Phthalocyanine compound synthesizer

A technology for synthesizing device and compound, applied in the field of phthalocyanine compound synthesizing device, can solve problems such as insufficient production equipment and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

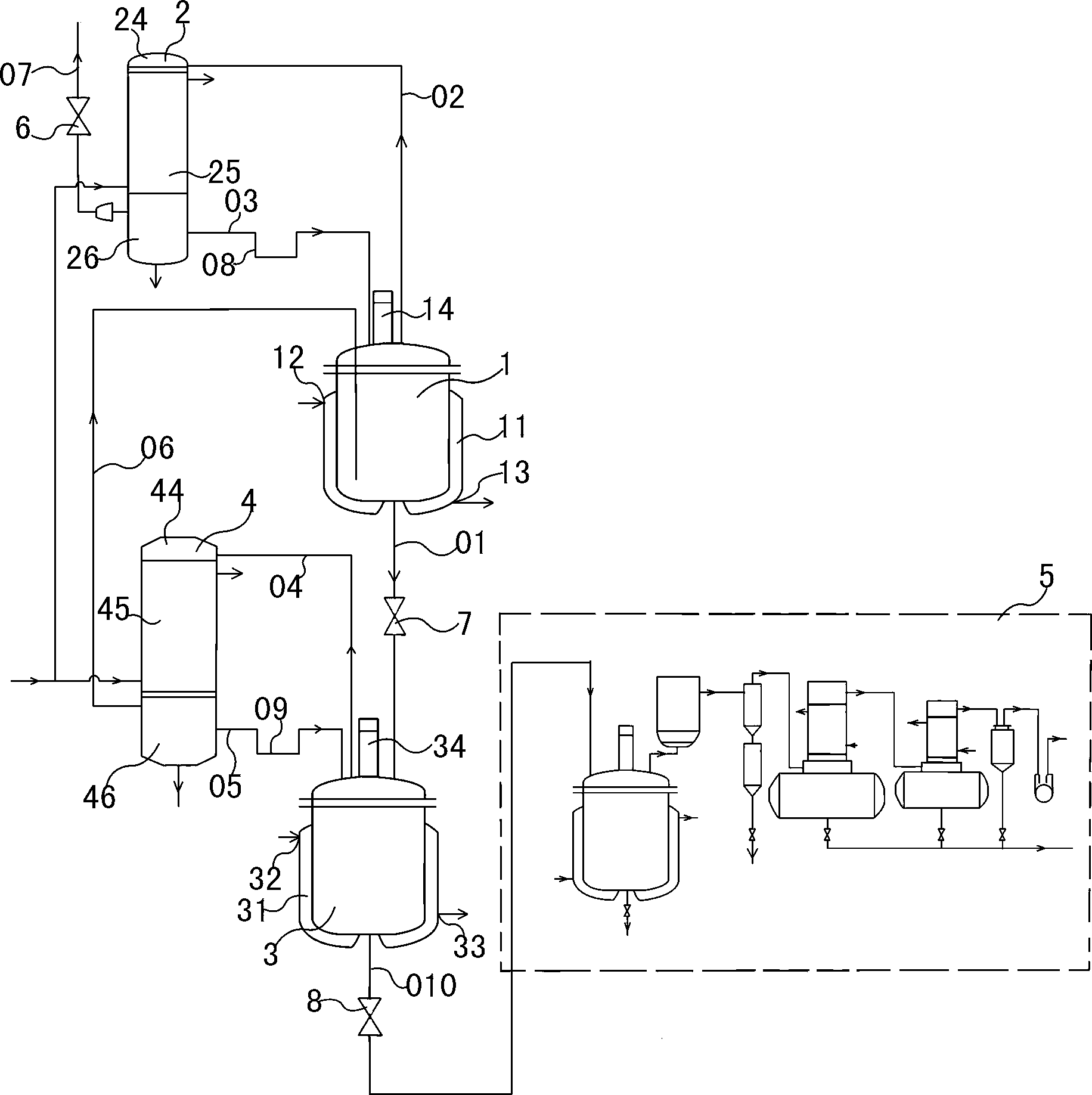

[0062] Such as figure 1 As shown, the phthalocyanine compound synthesis device includes a first reactor 1 , a first condenser 2 , a second reactor 3 , a second condenser 4 and a vacuum drying device 5 .

[0063] The cavity of the first reaction kettle 1 communicates with the cavity of the second reaction kettle 3 through the first material conveying pipe 01 .

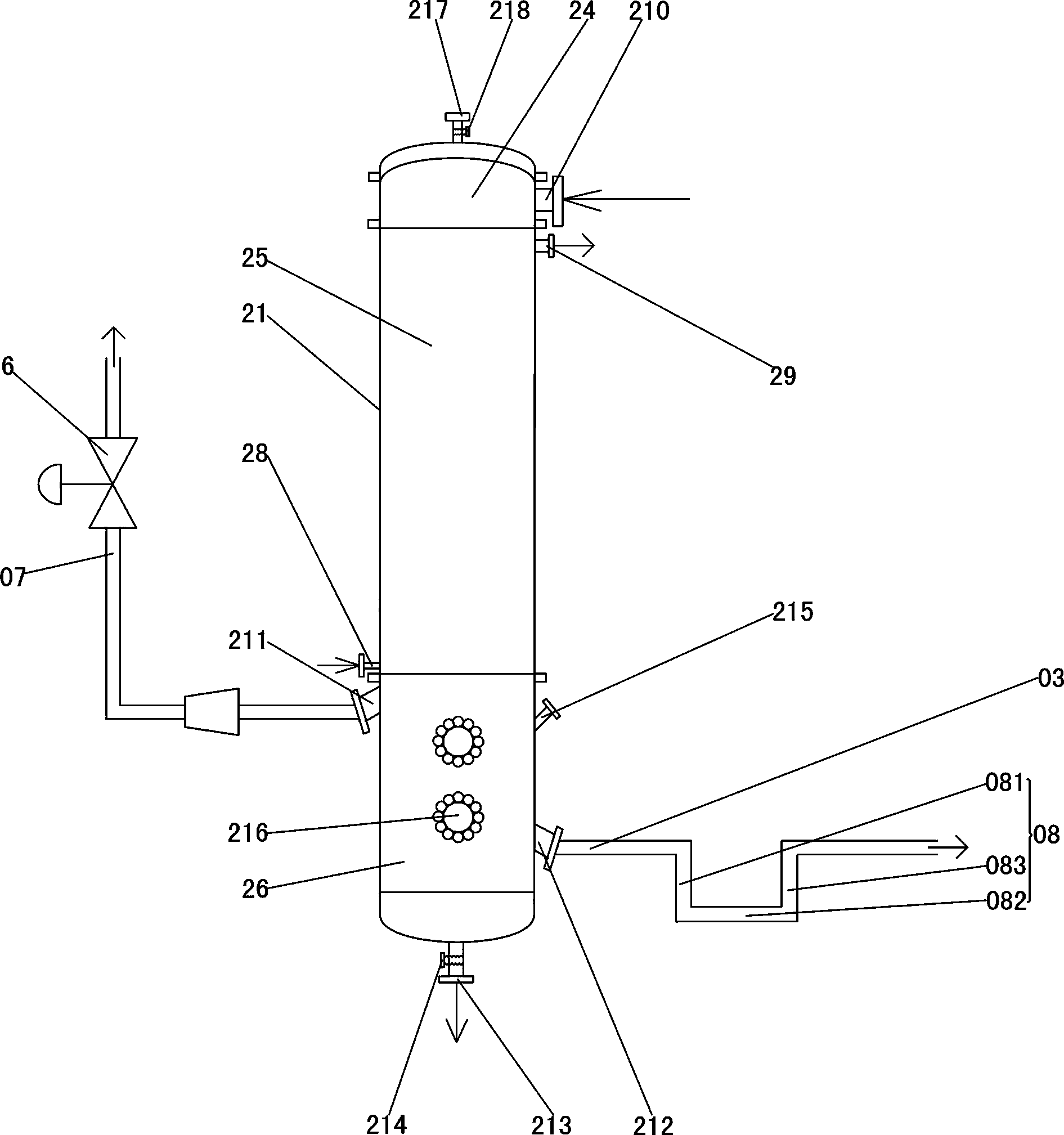

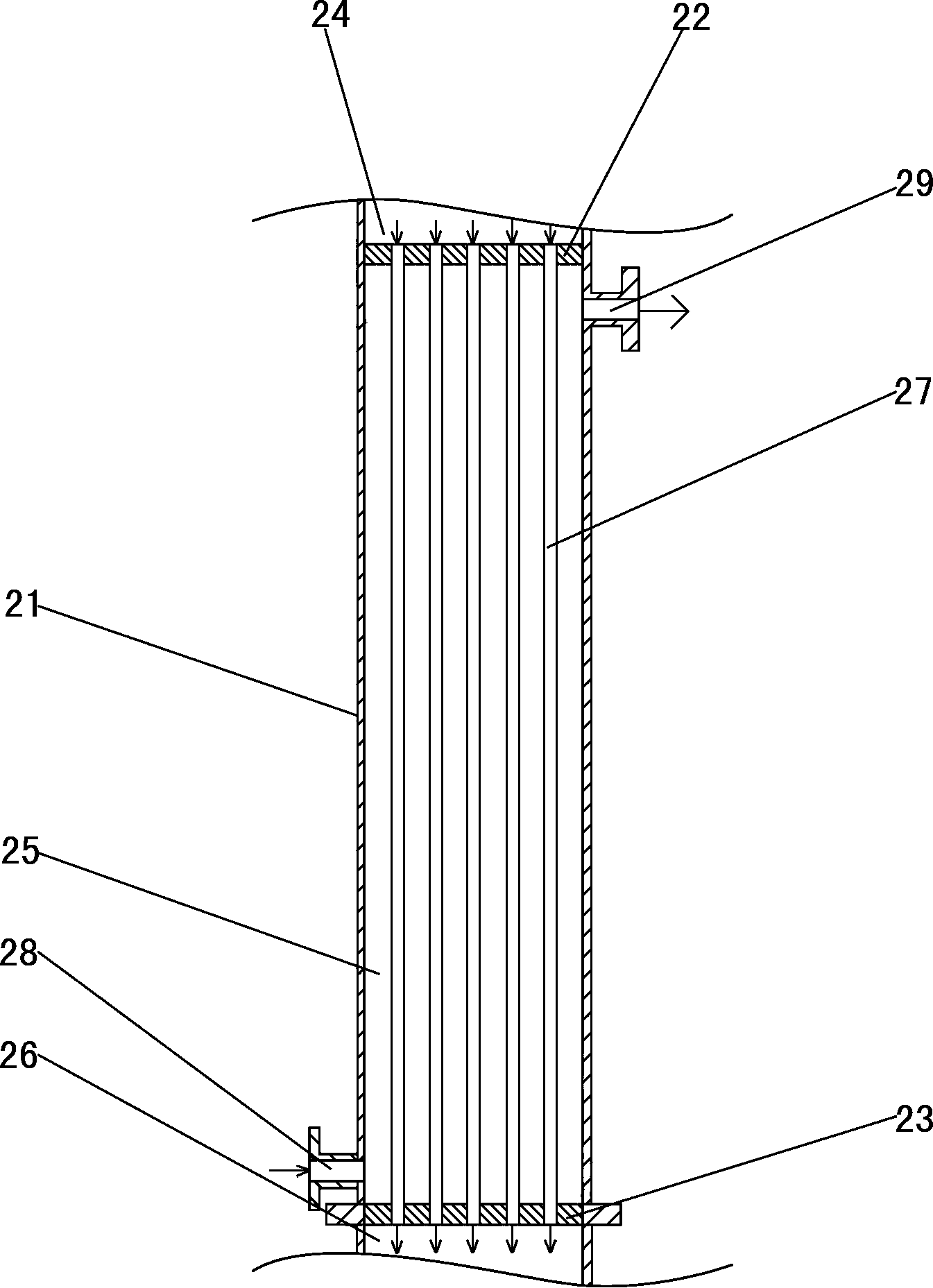

[0064] refer to figure 2 and image 3 , the first condenser 2 comprises a first condenser housing 21, a first upper partition 22 and a first lower partition 23 are arranged in the first condenser housing 21, the first upper partition 22 and the first lower partition The plate 23 divides the first condenser shell 21 into a first upper air chamber 24, a first condensation chamber 25 and a first liquid storage chamber 26 arranged from top to bottom, and a plurality of first condenser chambers 25 are provided with Heat exchange tube 27, the lower end of the first heat exchange tube 27 communicates with the cavity of the...

Embodiment 2

[0117] Such as Figure 9 As shown, the present embodiment is different from Embodiment 1 in that: in the vacuum drying device 5, the cyclone separator 53 is not provided between the buffer tank 52 and the third condenser 54, and the gas delivery pipe 503 is omitted. ; The steam outlet 522 of the buffer tank 2 communicates with the cavity of the third lower air chamber 546 through the gas delivery pipe 502 .

[0118] The rest of the structure of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0120] Such as Figure 10 As shown, the vacuum drying device of the present embodiment comprises a third reaction kettle 51, a third condenser 54, a first solvent recovery tank 55 and a vacuum pump 59, and the cavity of the third reaction kettle 51 is connected with the third downgas through the gas delivery pipe 501. The cavity of the chamber 546 is communicated, and the cavity of the third upper air chamber 544 is communicated with the vacuum pump 59 through the gas delivery pipe 506 . The positional relationship and connection relationship between the third condenser 54 and the first solvent recovery tank 55 are the same as those in Embodiment 1, and the rest of the structure of this embodiment is also the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com