Die casting method for light alloy

A light alloy and die-casting technology, which is applied in the field of light alloy die-casting to achieve the effects of reducing tensile stress, enhancing flatness and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

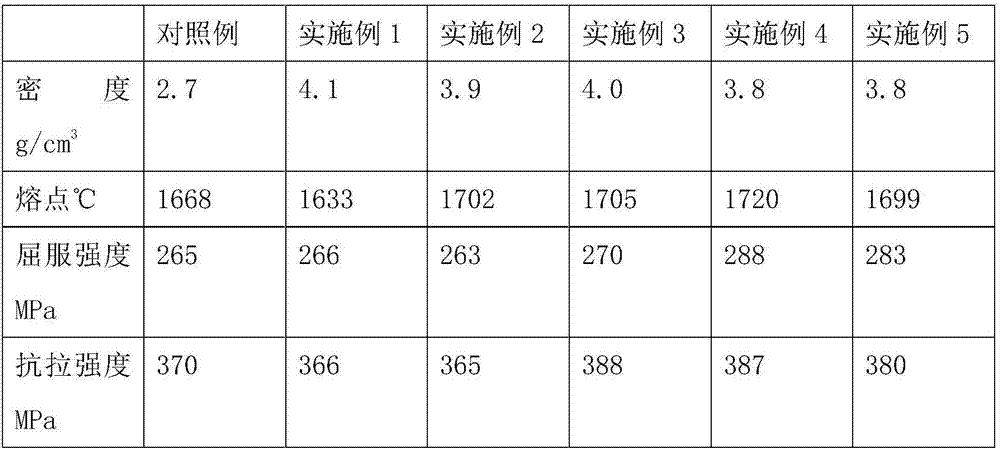

Examples

Embodiment 1

[0020] This embodiment provides a die-casting method for a light alloy, which specifically includes the following steps:

[0021] S1 Raw material preparation: place the light alloy in a heating furnace under a vacuum environment and continue heating. The temperature of the heating furnace is 700°C until the light alloy slowly melts into molten metal;

[0022] S2 Aluminum powder addition: In a vacuum environment, add a certain amount of aluminum powder to the molten metal prepared in S1, then place the molten metal in a heating furnace for heating, and continuously mechanically stir it through graphite rods for 1 hour during the heating process;

[0023] S3 exhaust: inert gas is passed into the molten metal obtained in S2 in a vacuum environment, and the molten metal is continuously affected by ultrasonic waves, and the undissolved bubbles in the molten metal are removed through the joint action of air blowing and ultrasonic vibration;

[0024] S4 Injection molding: inject the ...

Embodiment 2

[0032] This embodiment provides a die-casting method for a light alloy, which specifically includes the following steps:

[0033] S1 Raw material preparation: place the light alloy in a heating furnace under a vacuum environment and continue heating, the temperature of the heating furnace is 710°C, until the light alloy slowly melts into molten metal;

[0034] S2 Aluminum powder addition: In a vacuum environment, add a certain amount of aluminum powder to the molten metal prepared in S1, and then place the molten metal in a heating furnace for heating. During the heating process, mechanically stir continuously through graphite rods for 1.2 hours ;

[0035] S3 exhaust: inert gas is passed into the molten metal obtained in S2 in a vacuum environment, and the molten metal is continuously affected by ultrasonic waves, and the undissolved bubbles in the molten metal are removed through the joint action of air blowing and ultrasonic vibration;

[0036] S4 Injection molding: inject ...

Embodiment 3

[0044] This embodiment provides a die-casting method for a light alloy, which specifically includes the following steps:

[0045] S1 Raw material preparation: place the light alloy in a heating furnace under a vacuum environment and continue heating, the temperature of the heating furnace is 720°C, until the light alloy slowly melts into molten metal;

[0046] S2 Aluminum powder addition: In a vacuum environment, add a certain amount of aluminum powder to the molten metal prepared in S1, and then place the molten metal in a heating furnace for heating. During the heating process, it is continuously mechanically stirred by a graphite rod for 1.5 hours ;

[0047] S3 exhaust: inert gas is passed into the molten metal obtained in S2 in a vacuum environment, and the molten metal is continuously affected by ultrasonic waves, and the undissolved bubbles in the molten metal are removed through the joint action of air blowing and ultrasonic vibration;

[0048]S4 Injection molding: inj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com