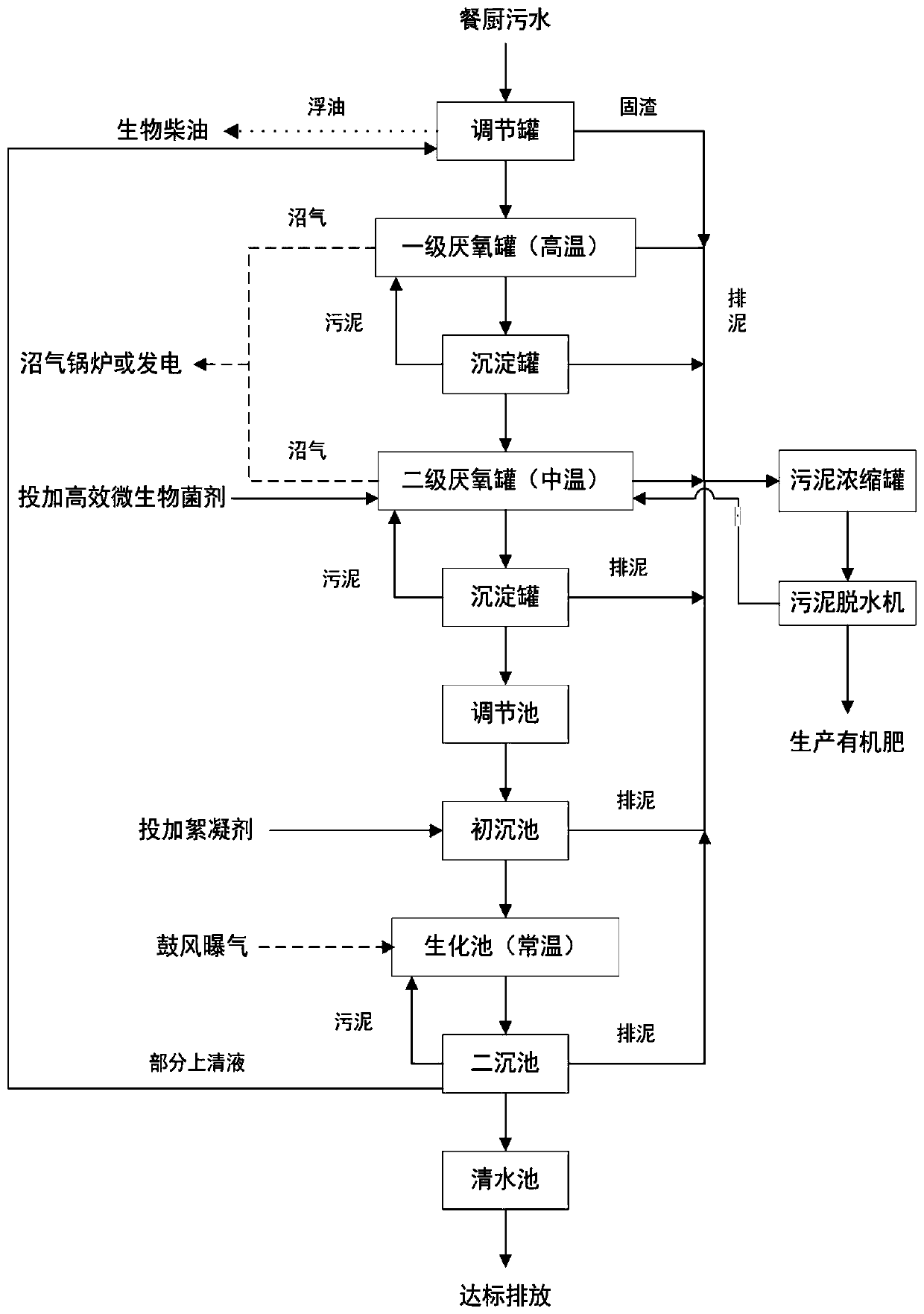

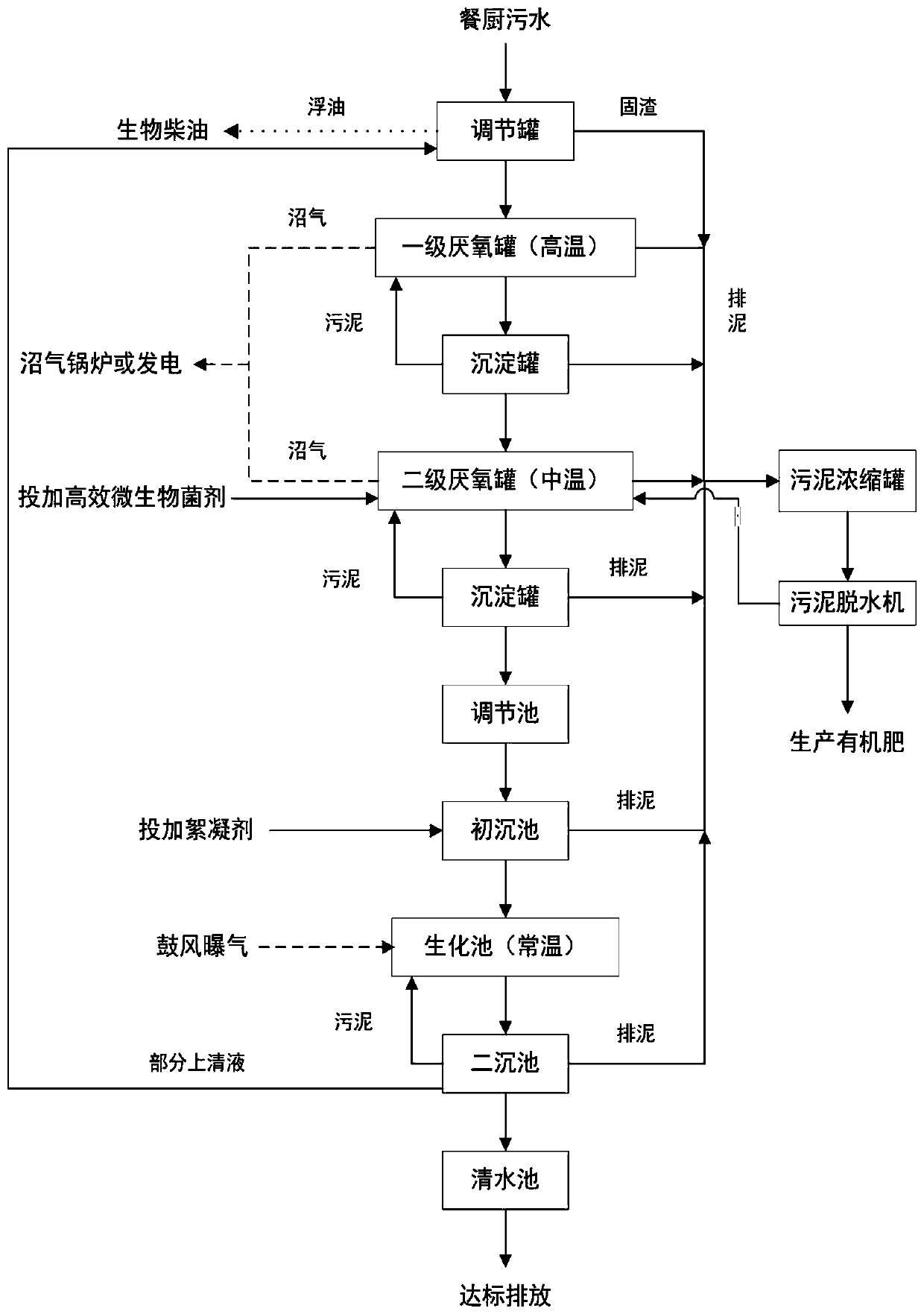

Multi-stage treatment process for kitchen sewage

A technology for treating process and sewage, which is applied in biological water/sewage treatment, water/sludge/sewage treatment, anaerobic digestion treatment, etc. It can solve the problems of sewage treatment process that is difficult to meet the discharge standards, the biochemical treatment system collapses, and the treatment effect is unstable to avoid acid inhibition, reduce the concentration of organic matter, and improve energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A multi-stage treatment process for kitchen sewage, comprising the following specific steps:

[0043] (1) The kitchen sewage is pretreated by the front-end machine to remove the kitchen waste, and enters the regulating tank for stirring and homogenizing the sewage, and separates the three phases of solid, liquid and oil, and the temperature of the sewage in the regulating tank is 58°C;

[0044] (2) The sewage treated by the regulating tank enters the first-level anaerobic high-temperature fermentation tank for high-temperature anaerobic fermentation. The temperature of the first-level anaerobic high-temperature fermentation tank is controlled at 50-58 ° C, and the hydraulic retention time is about 20 days. The treatment produces biogas, The biogas is dehydrated through the gas-water separator and collected by the biogas flame arrester in turn;

[0045] (3) The sewage treated by the first-level anaerobic high-temperature fermentation tank enters the sedimentation tank fo...

Embodiment 2

[0052] On the basis of Example 1, the temperature of the sewage in the regulating tank before the primary anaerobic is 62°C; the temperature of the primary anaerobic high-temperature fermentation tank is controlled at 50-58°C, and the hydraulic retention time is 15d; The treatment temperature of the fermenter is controlled at 30-38°C, and the hydraulic retention time is 15d; the second-level medium-temperature anaerobic fermenter is added with suspended biological filler, and the filling volume of the filler is 1 / 3 of the fermenter volume; when performing A / O biochemical treatment In Pond A for denitrification and denitrification, the temperature is controlled at 20-40°C, the DO content is controlled to be less than 0.5mg / l, and the residence time is 4d; then it enters the O pool for nitrification reaction, and the temperature is controlled at 20-30°C; Fiber soft filler, at the same time put into sludge to domesticate and cultivate into activated sludge, form an aerobic contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com