Turbocharger with two-stage supercharging function

A turbocharger and supercharger technology, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc., can solve problems such as insufficient low-speed torque, poor acceleration performance, and slow transient response, so as to avoid air leakage phenomenon, the effect of improving reliability and accelerating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

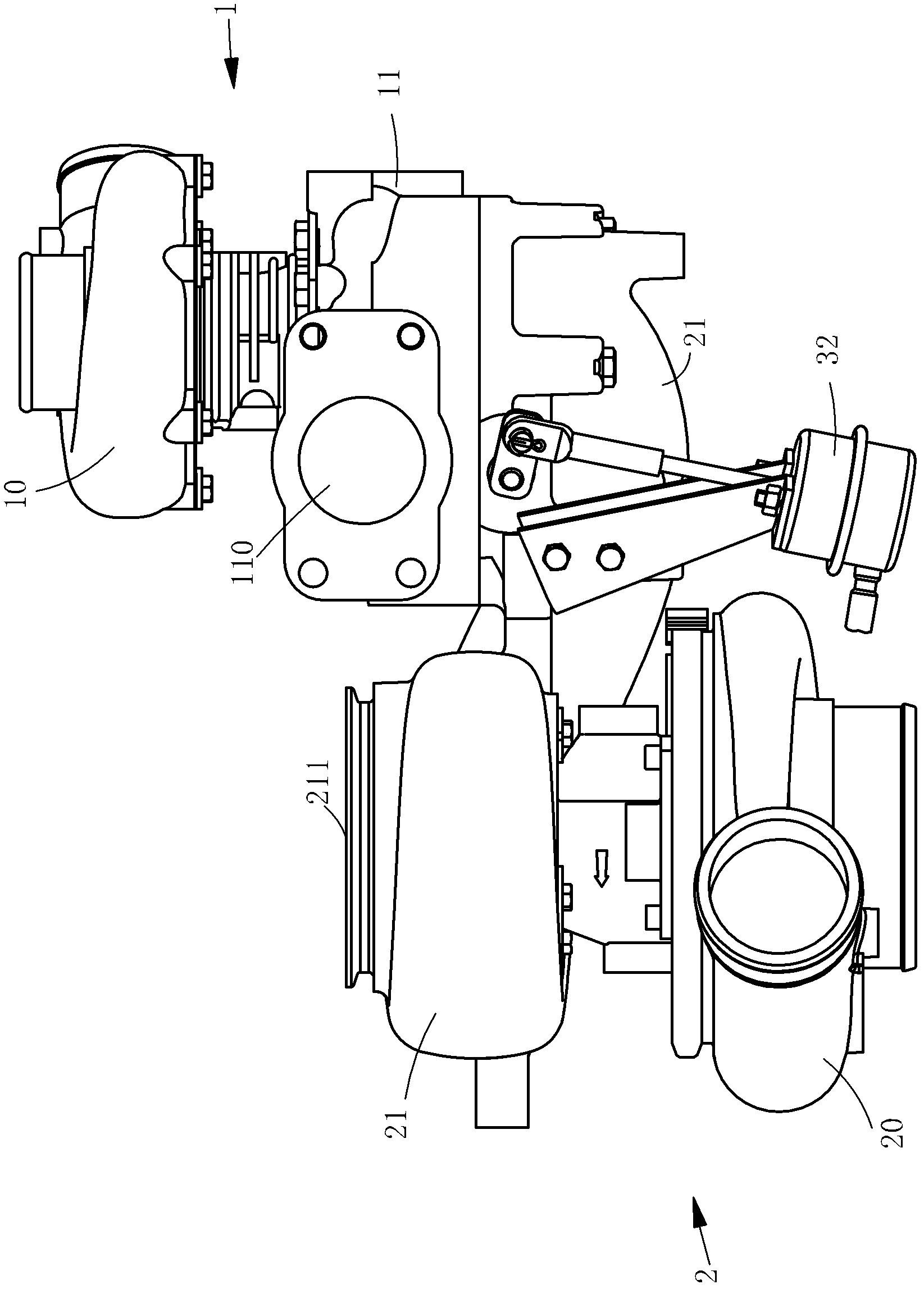

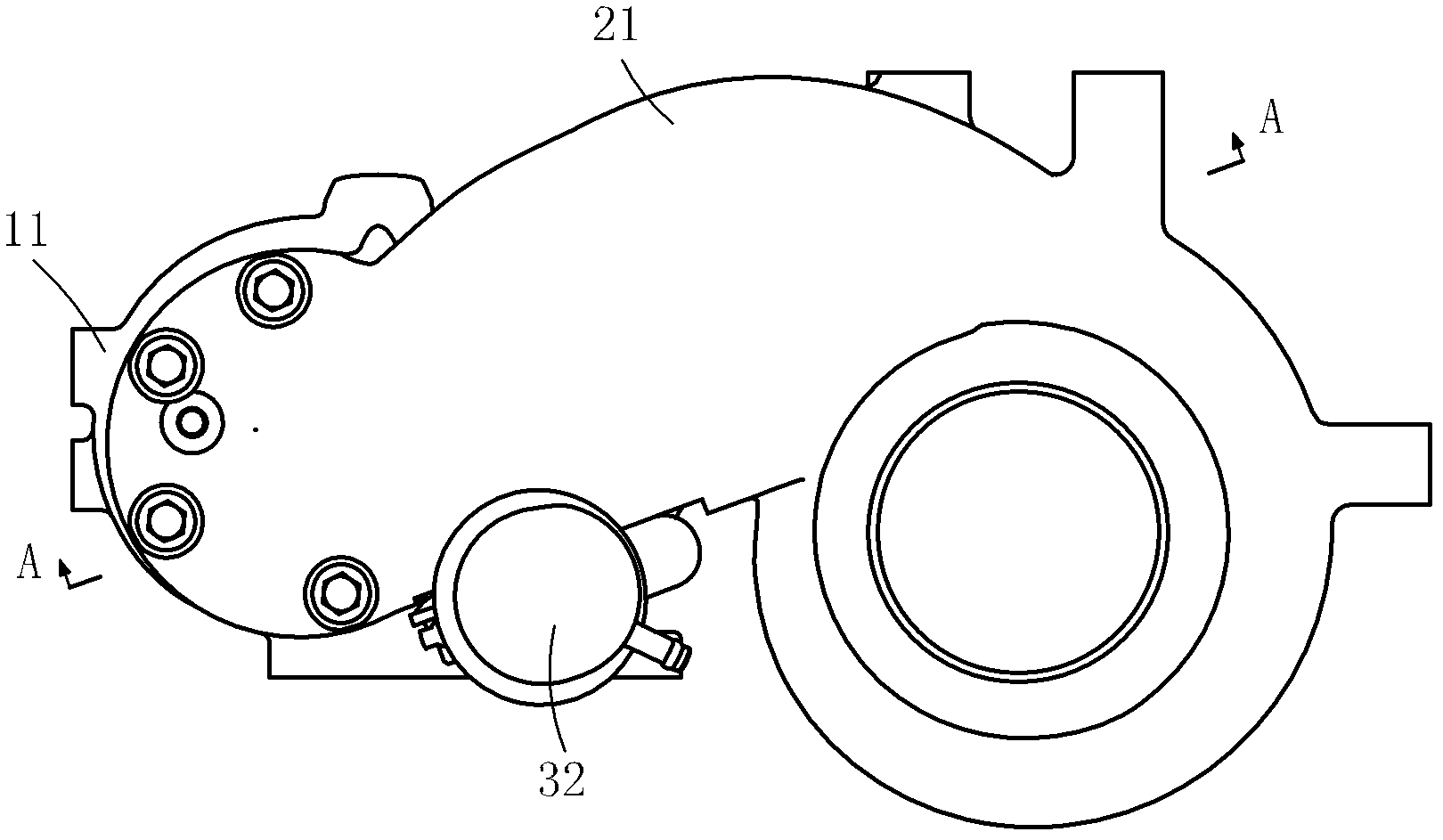

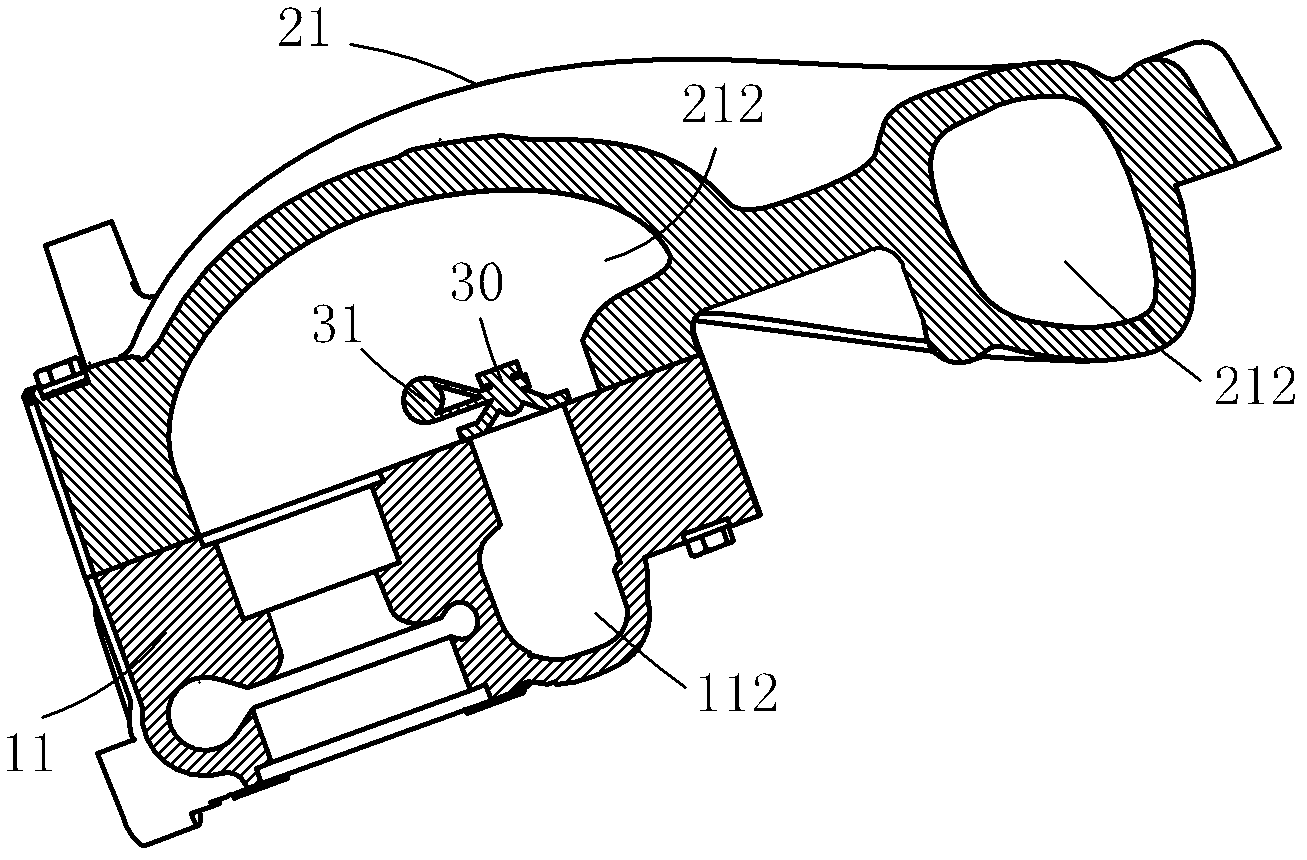

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Commonly shown, a two-stage supercharging turbocharger includes a high-pressure supercharger 1 and a low-pressure supercharger 2 connected together. The high-pressure supercharger 1 includes a high-pressure compressor 10 and a high-pressure turbine. A high-pressure turbine casing 11 is provided, and a high-pressure turbine casing 11 is provided with a high-pressure turbine exhaust port 111 and a high-pressure turbine air inlet 110 for connecting an engine exhaust pipe; the low-pressure supercharger 2 includes a low-pressure compressor 20 and a low-pressure turbine, The low-pressure turbine is provided with a low-pressure turbine housing 21 outside, and the low-pressure turbine housing 21 is provided with a low-pressure turbine inlet 210 and a low-pressure turbine exhaust port 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com