Motor stator fixture

A motor stator and fixture technology, applied in the field of tooling and fixtures, can solve the problems of motor stator pressure deformation, poor applicability, and low precision, and achieve the effects of avoiding damage and deformation, easy operation, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

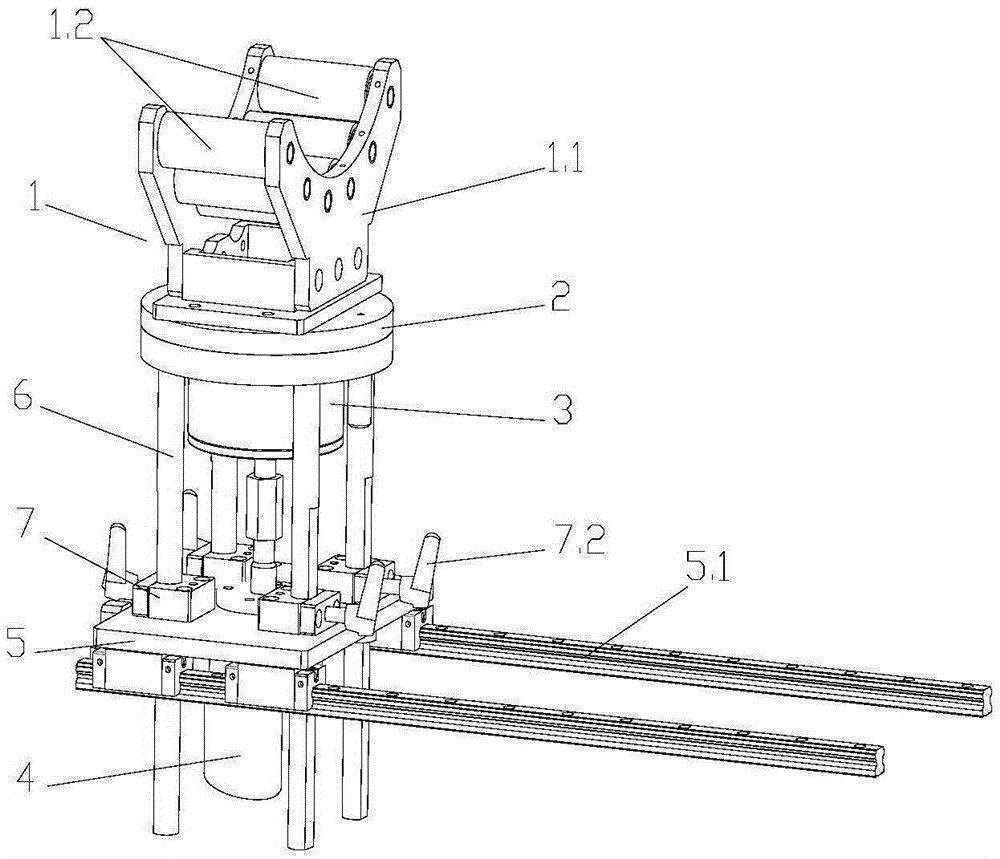

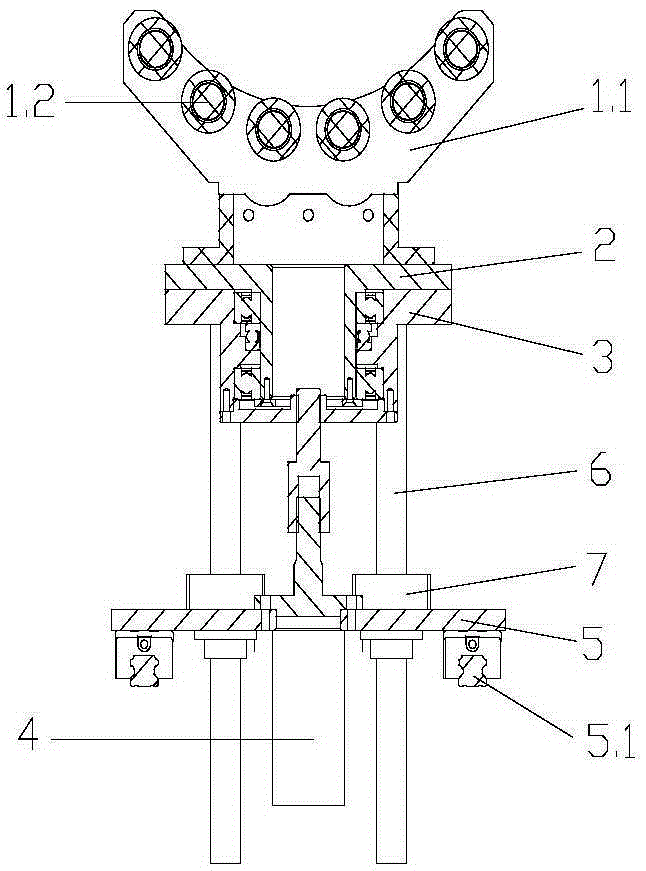

[0014] Embodiment 1: as figure 1 , figure 2 A motor stator fixture shown includes a stator bracket 1 and a rotating seat 2 at the bottom of the stator bracket 1. The bottom of the rotating seat 2 is provided with a bracket seat 3 that is rotatably connected to the rotating seat 2. The bracket seat 3 is sleeved On the protrusion of the shaft center of the bottom surface of the rotating base 2, a bearing connected between the protrusion and the bracket base 3 is provided, and evenly distributed positioning holes are arranged on the rotating base 2 and the bracket base 3, and the rotating base 1 is provided with There are locating pins that are movably connected, and the rotating seat 2 can adjust the angle to be positioned by the locating pins. The stator bracket 1 is composed of two opposite supporting plates 1.1 and a plurality of magnetic rollers 1.2 between the supporting plates 1.1. The plurality of magnetic rollers 1.2 are Arranged in an arc, and the upper part of the su...

Embodiment 2

[0015] Embodiment 2: as figure 1 , figure 2 A motor stator fixture shown includes a stator bracket 1 and a rotating seat 2 at the bottom of the stator bracket 1. The bottom of the rotating seat 2 is provided with a bracket seat 3 that is rotatably connected to the rotating seat 2. The bracket seat 3 is sleeved On the protrusion of the shaft center of the bottom surface of the rotating base 2, a bearing connected between the protrusion and the bracket base 3 is provided, and evenly distributed positioning holes are arranged on the rotating base 2 and the bracket base 3, and the rotating base 1 is provided with There are locating pins that are movably connected, and the rotating seat 2 can adjust the angle to be positioned by the locating pins. The stator bracket 1 is composed of two opposite supporting plates 1.1 and a plurality of magnetic rollers 1.2 between the supporting plates 1.1. The plurality of magnetic rollers 1.2 are Arranged in an arc shape, and the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com