Contact pressure control mechanism for molded case low-voltage circuit breaker

A low-voltage circuit breaker, contact pressure technology, applied in the direction of protection switch operation/release mechanism, etc., can solve the problem of unresolved contact pressure, affecting circuit breaker temperature rise, change, etc., to achieve current limiting and arc extinguishing, Improved opening speed and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

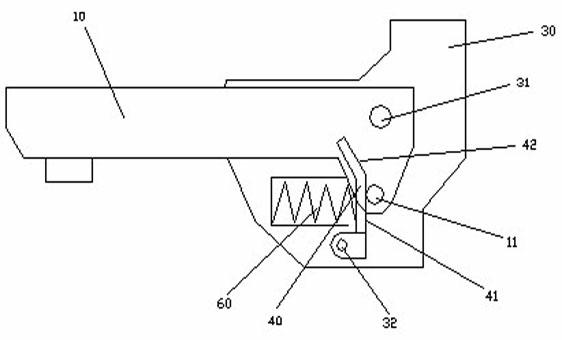

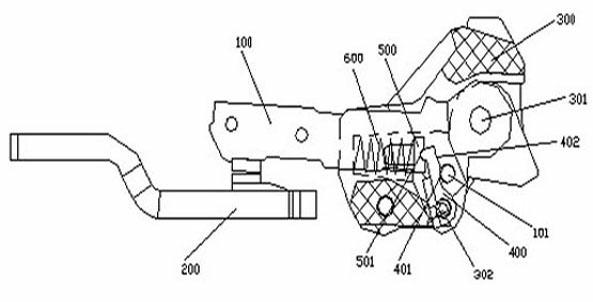

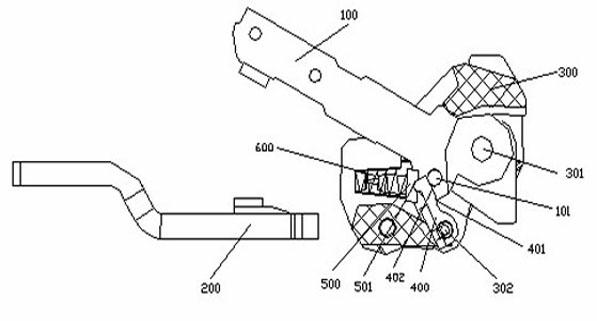

[0019] see Figure 2-6 , the low-voltage circuit breaker includes a rotating shaft 300 fixed therein, and the rotating shaft 300 rotates with the operating mechanism. The rear end of the moving contact 100 is the rotating end, and the rotating end is connected to the rotating shaft 300 through the first rotating central axis 301, so that the moving contact 100 surrounds the second rotating shaft. A rotation center shaft 301 rotates, and the first rotation center shaft 301 is parallel to the rotation axis of the rotation shaft 300 . The front end of the movable contact 100 is a movable end, and the movable end corresponds to the static contact 200 .

[0020] Located below the first central axis of rotation 301, a shaft 101 parallel to the first central axis of rotation 301 is provided on the movable contact 100; a second central axis of rotation 302 parallel to the axis 101 is provided on the rotating shaft 300 below the shaft 101 , the second rotating central shaft 302 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com