Rotor with inclined magnetic pole and asymmetric salient pole and high-performance permanent magnet motor

A permanent magnet motor, asymmetrical technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electromechanical devices, etc., can solve the problems of underutilized components, high torque ripple, difficult to realize, etc., to avoid torque density The effect of excessive attenuation, reduction of harmonic content, and no decrease in torque density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

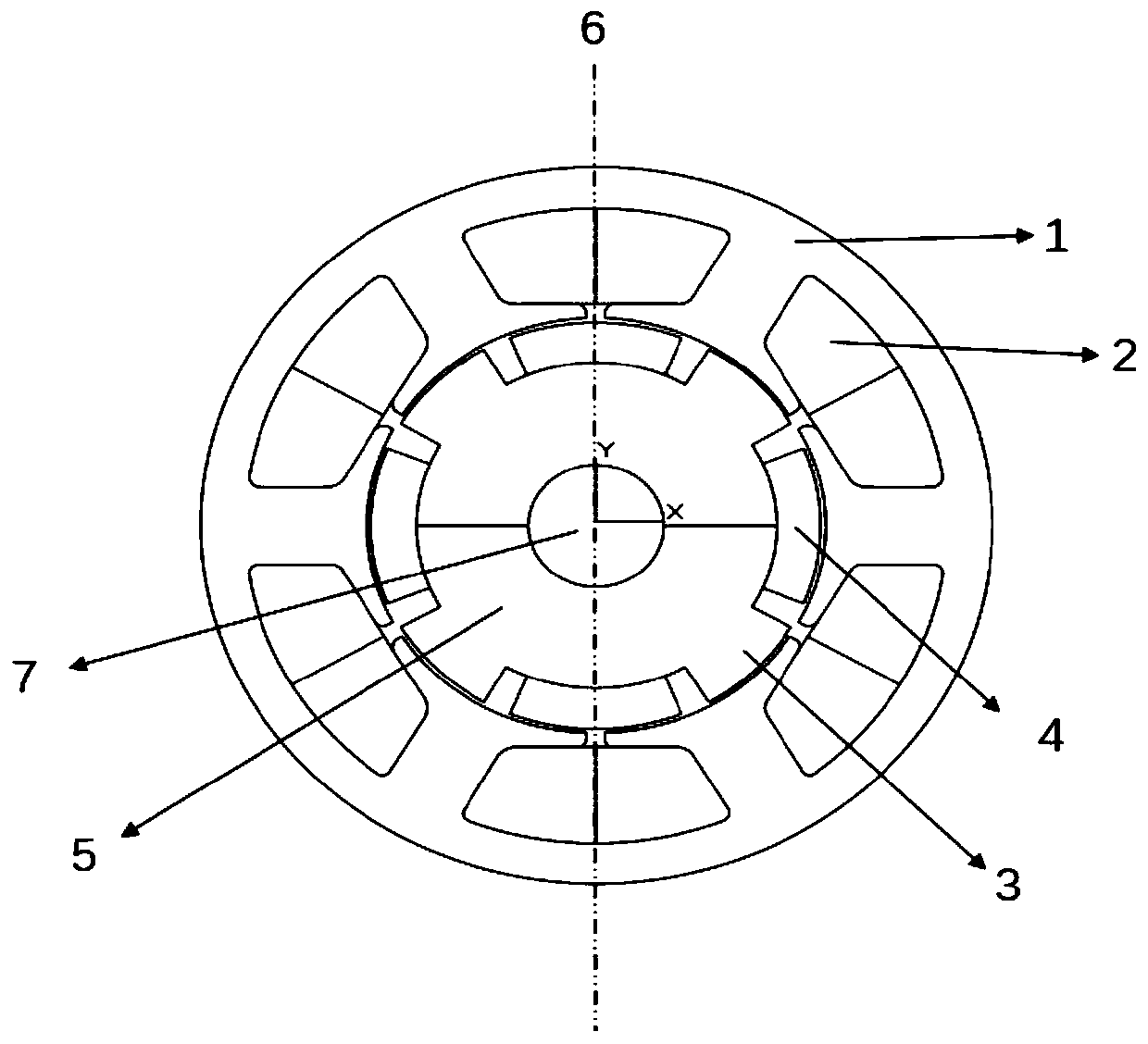

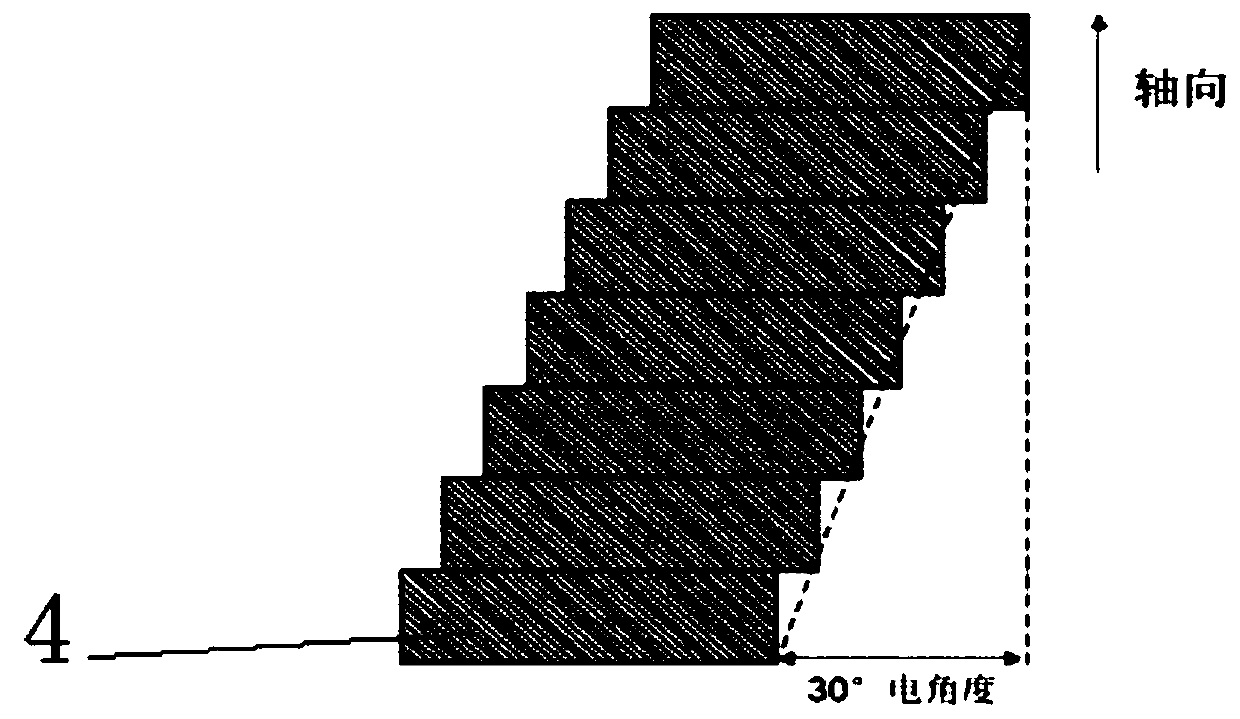

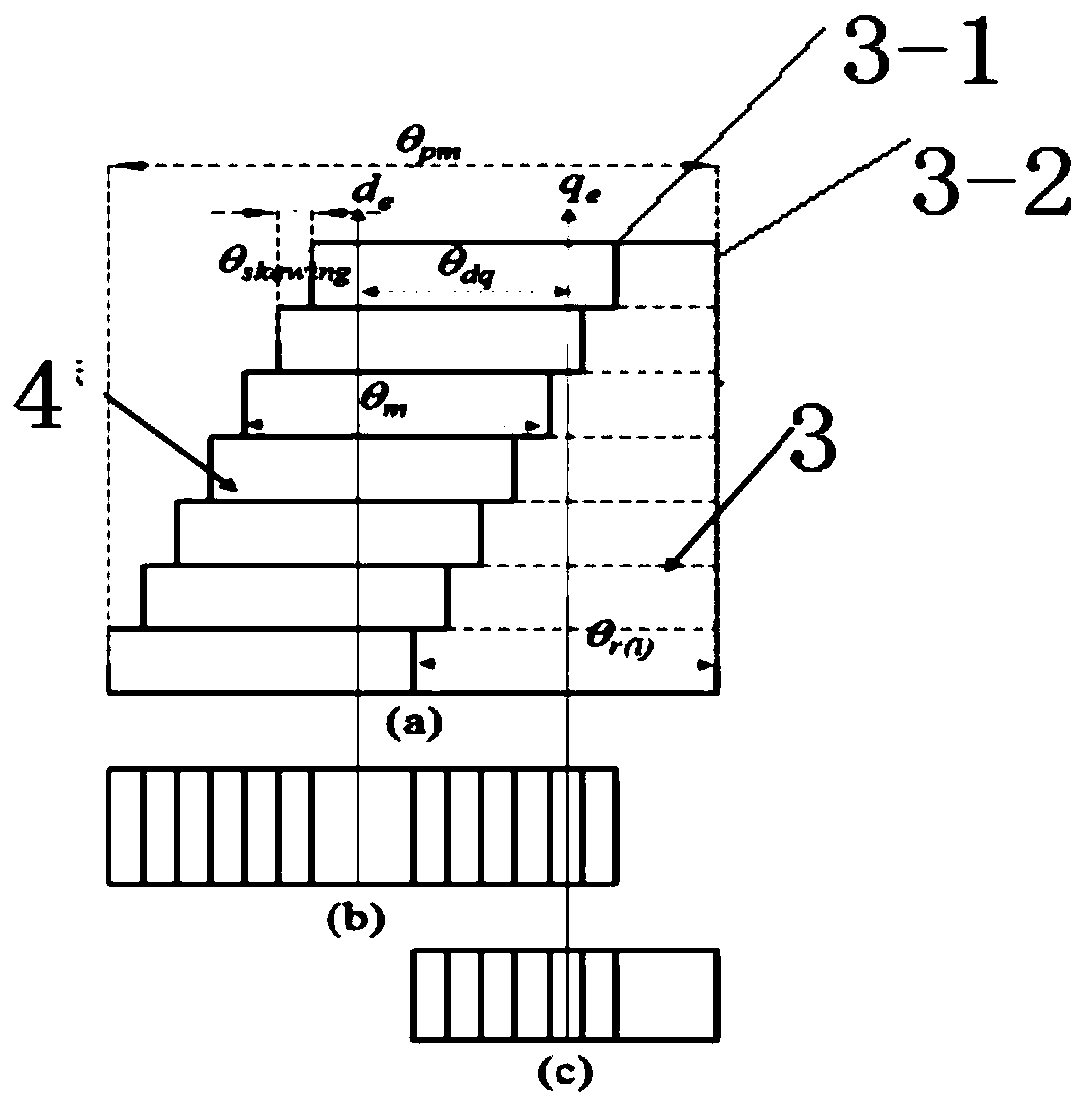

[0033] In the technical solutions disclosed in one or more embodiments, such as Figure 5 with 6 As shown, an asymmetrical rotor with inclined magnetic poles and salient poles includes a rotor core 5-2 and magnetic poles arranged on the rotor iron core 5-2, and each magnetic pole includes salient poles 3 and Rotor slot 5-1, segmented permanent magnets 4 are arranged in the rotor slot 5-1, and the permanent magnets 4 of each segment are extended and arranged along the direction of the rotating shaft 7, and are set in sequence on the circumference of the rotor core 5-2. Misalignment of angles. In this disclosure, the tilted magnetic poles obtained by using the 4-stage dislocation method of permanent magnets can effectively weaken the cogging effect and reduce the cogging torque when applied to permanent magnet motors, and at the same time reduce the harmonic content of back electromotive force to generate sinusoidal or quasi-sinusoidal countermeasures. The electromotive force ...

Embodiment 2

[0049] This embodiment provides a permanent magnet motor with tilted rotor magnetic poles, including a rotor, a stator and a rotating shaft, the rotor and the stator are coaxially arranged, the rotor is arranged inside the stator through the rotating shaft, and there is a gap between the rotor and the stator, so The rotor adopts the rotor with inclined magnetic poles and asymmetry described in Embodiment 1.

[0050] Such as Image 6 As shown, the stator includes a stator core and a stator slot, and a stator winding 2 is arranged in the stator slot, and a radial gap 18 is formed between the stator winding 2 and the outer periphery of the rotor 5 .

[0051] The stator slots are arranged at equal intervals along the circumferential direction on the inner periphery of the stator 1 , and extend from the side of the stator core to the direction of the rotating shaft in a convex shape. The stator can be a common six-slot structure.

[0052] In Embodiment 2, by using an asymmetrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com