Hydraulic energy recovery system

A technology of energy recovery and hydraulic circuit, applied in the field of hydraulic circuit, can solve problems such as limitation, affecting the overall performance of the circuit, and impossible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

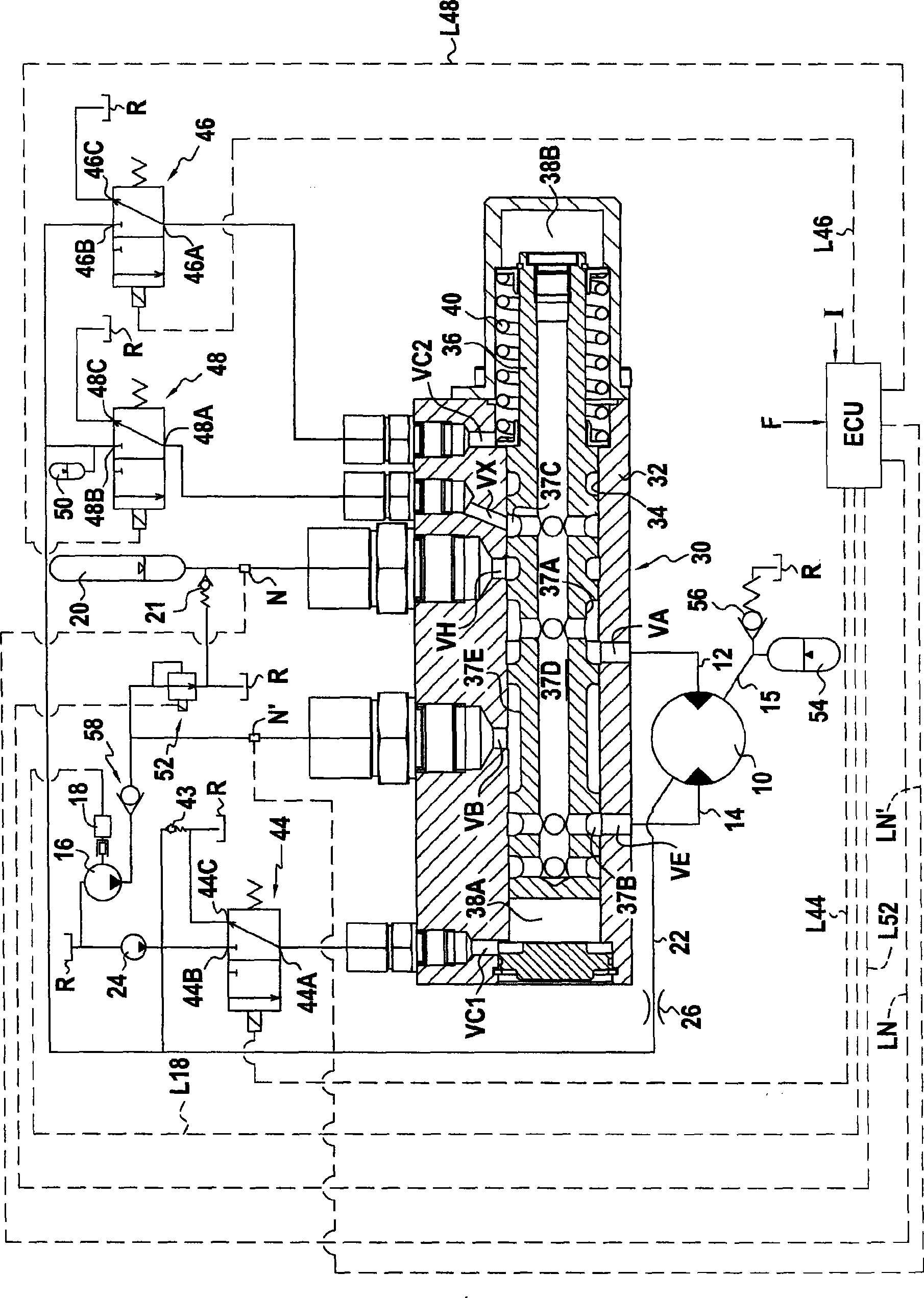

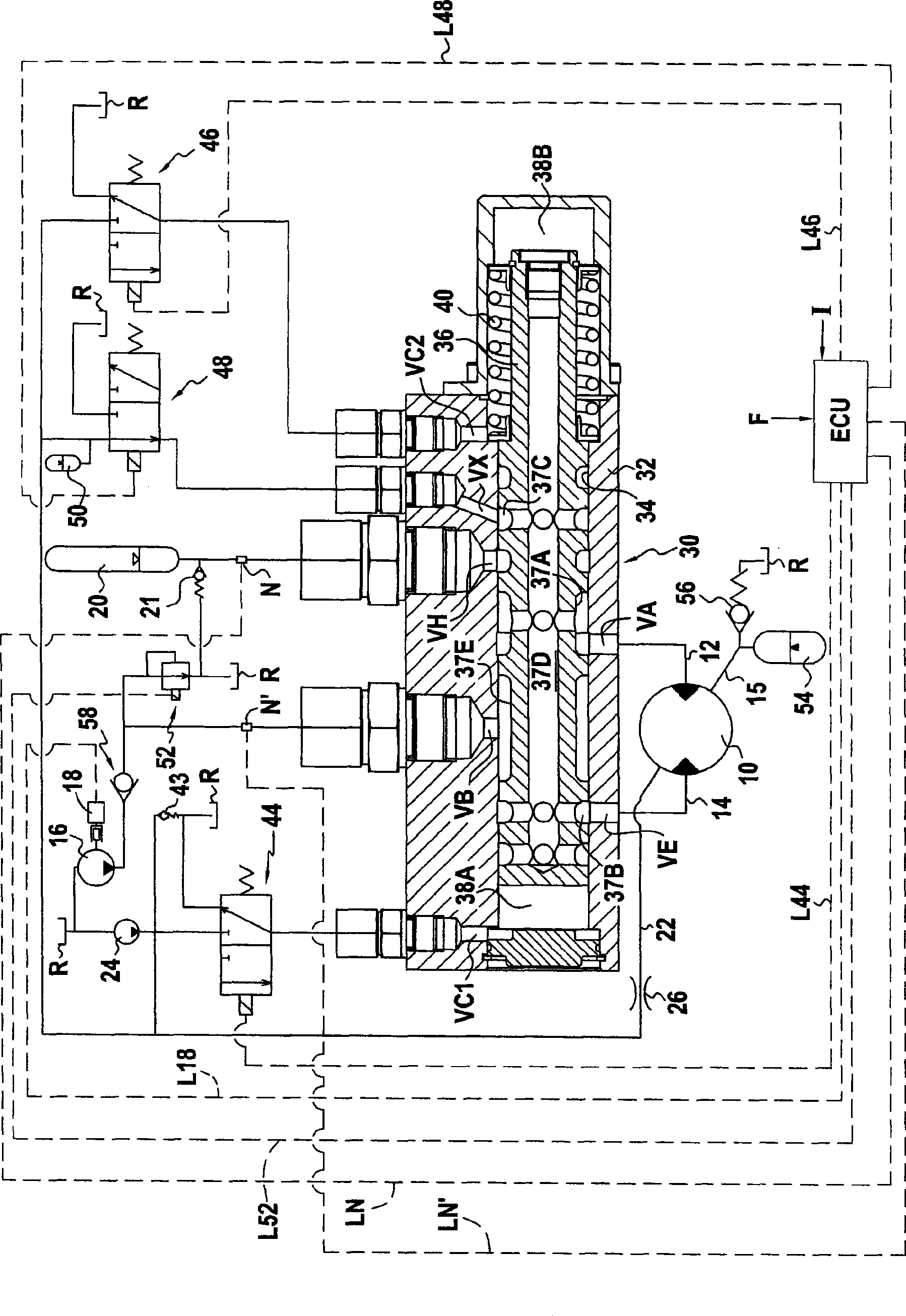

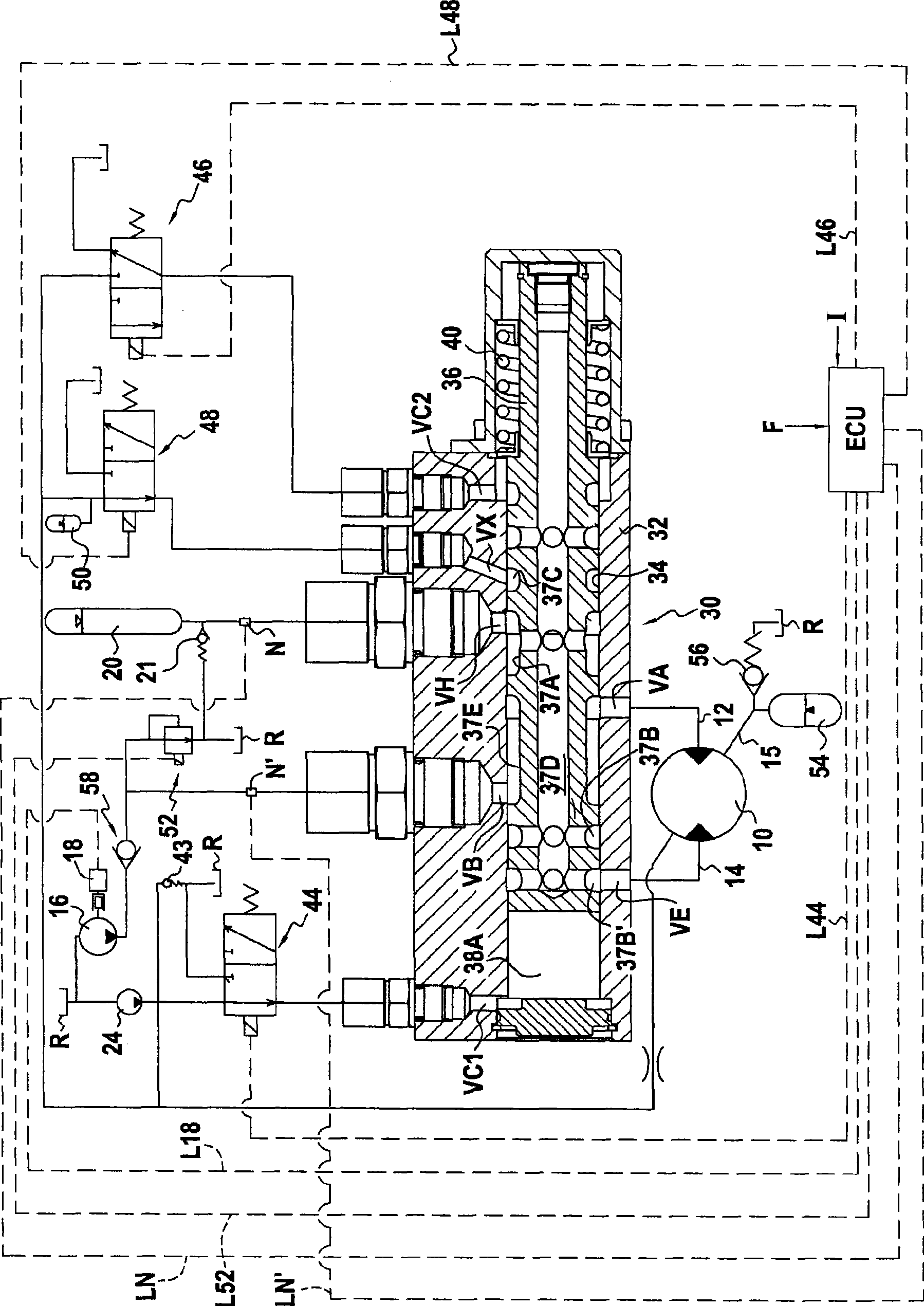

[0032] exist Figure 1A to Figure 1E The circuit shown in includes a hydraulic motor 10 having two main conduits 12 and 14 for supplying fluid to or draining fluid from said motor. The circuit also includes a low pressure liquid source 16 formed by a high flow rate booster pump pumping liquid from a pressureless reservoir R (reservoir at atmospheric pressure). The pump is selected to be adapted to deliver fluid at a velocity sufficient to feed fluid into the hydraulic motor when the motor is at its highest speed in an energy recovery configuration. When having multiple motors in a circuit, it is preferable to use the same high flow rate booster pump sized, when the motor is at its highest speed, to supply fluid to the different motors sufficiently without creating The velocity of the air pockets to transport the liquid.

[0033] The pump 16 is driven by an engine, which may be the vehicle's conventional propulsion engine. This circuit is provided with means for activating o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com