Axial magnetic field printed circuit board permanent magnet brushless DC motor

A permanent magnet brushless DC, printed circuit board technology, applied in the shape/style/structure of winding conductors, can solve the problems of high labor and material costs, unstable quality, large eddy current loss, etc., and achieve flexible and changeable design , Eliminate eddy current loss, improve the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a specific embodiment of the present invention, and the present invention will be further described in conjunction with the accompanying drawings.

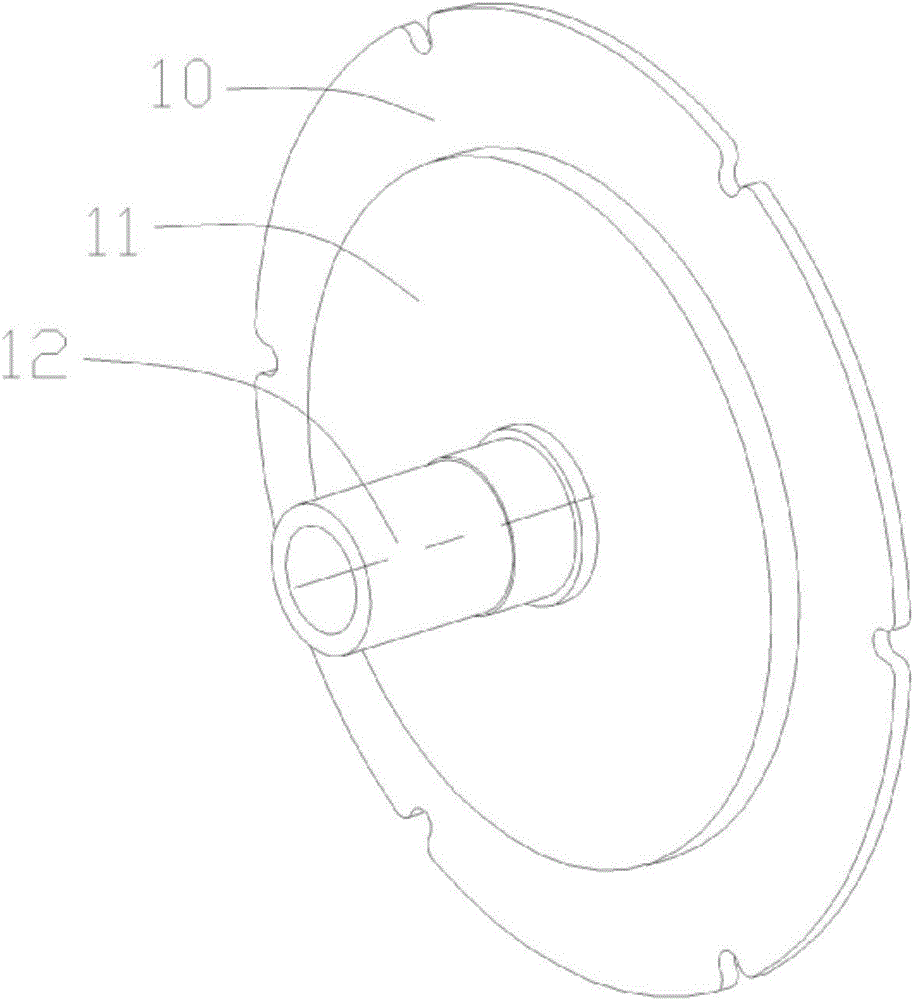

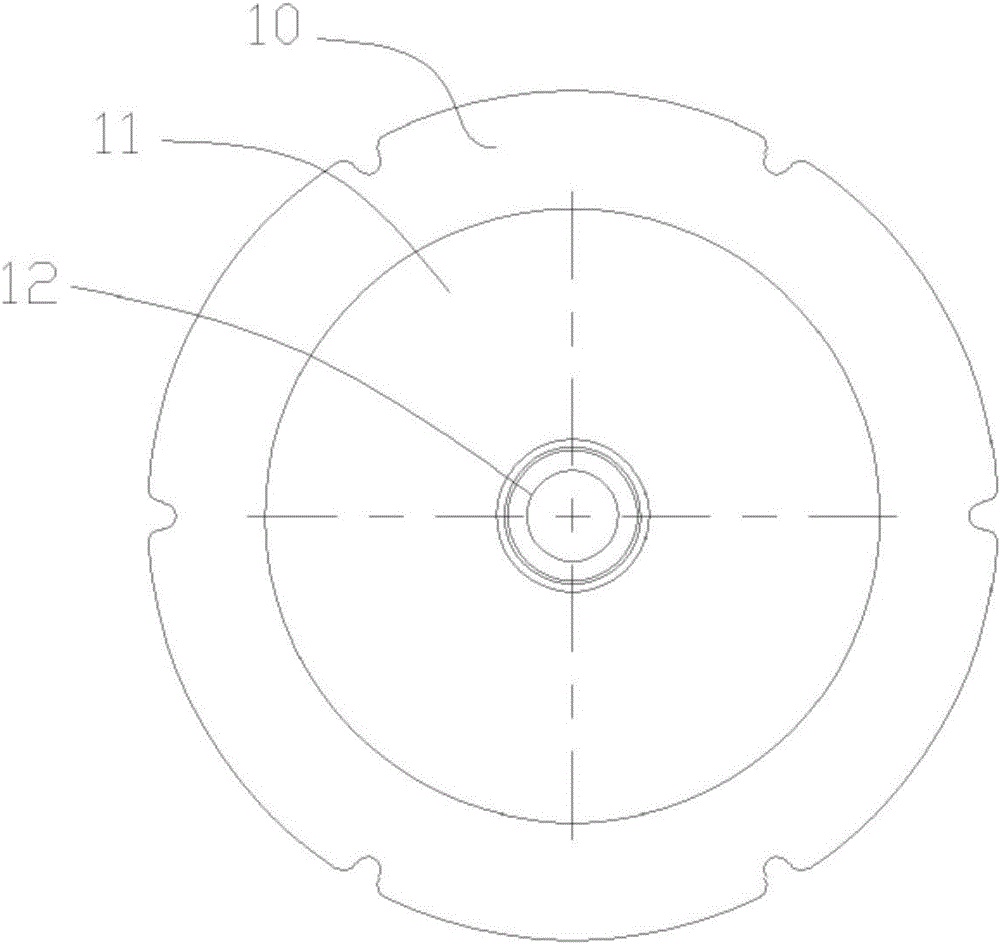

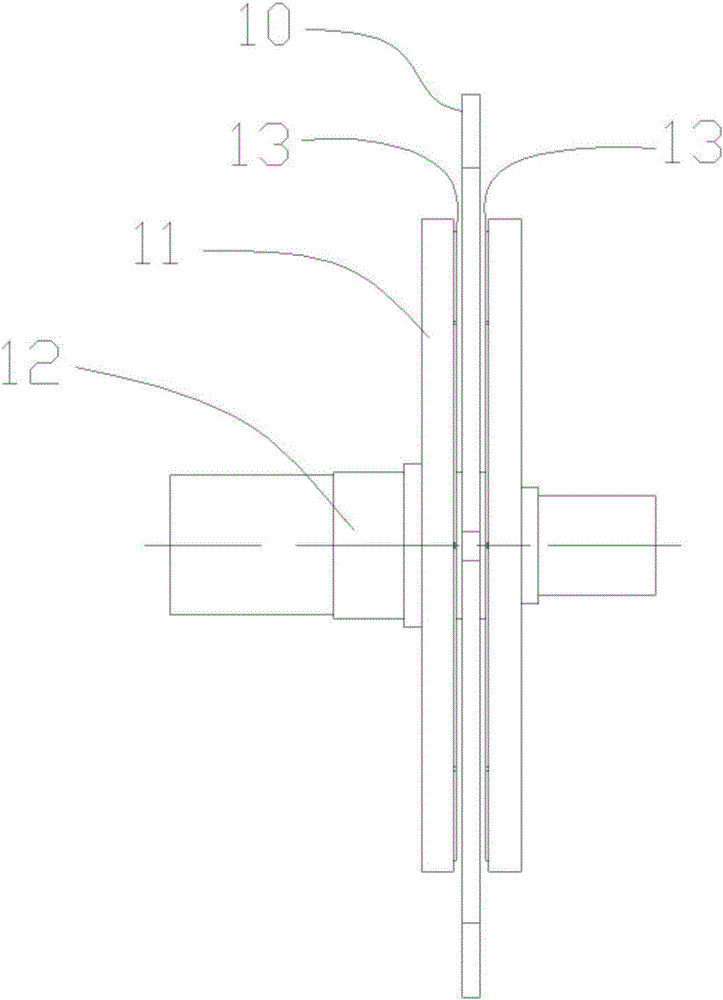

[0026] Such as Figure 1A , Figure 1B and Figure 1C As shown, an axial magnetic field printed circuit board permanent magnet brushless DC motor; a pair of symmetrically arranged turntables 11 are installed on the rotating shaft 12, and permanent magnets 13 are fixed on the opposite surfaces of the two turntables 11; The printed circuit board 10 arranged in parallel with the turntable 11, the rotating shaft 12 has a positioning platform for maintaining the distance between the permanent magnets 13 embedded in the two rotor turntables 11, so that the magnetic pole surface of each permanent magnet 13 and the printed circuit board 10 winding Parallel with equal spacing.

[0027] combine Figure 3A , Figure 3B As shown, the printed circuit board 10 is provided with a winding terminal 30, and a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com