Same-distribution-angle hydraulic cylinder motor

A hydraulic cylinder and equal distribution technology, applied in the field of mining hydraulic motors, can solve the problems of high safety factor of underground workers, potential safety hazards of high-temperature hot gas, and restrictions on the development of underground equipment, so as to achieve more effective working hours and improve production safety Coefficient, the effect of solving explosion-proof problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

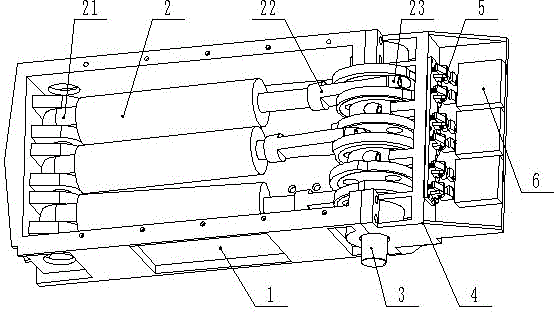

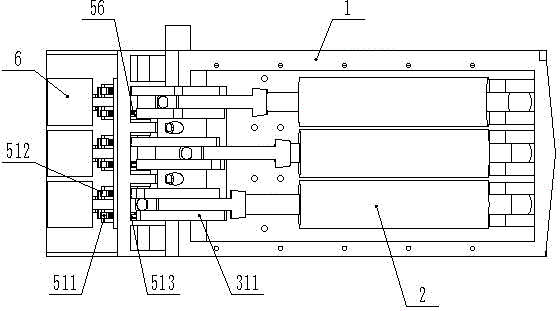

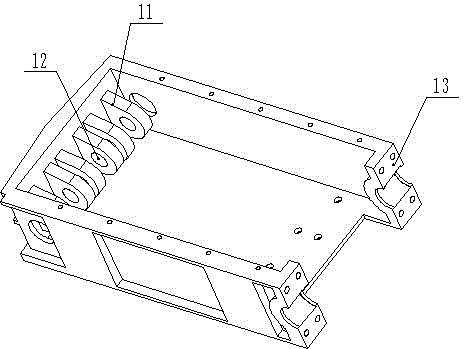

[0037] Such as figure 1 — image 3As shown, the equal distribution angle hydraulic cylinder motor includes a box body 1, three hydraulic cylinders 2, a crankshaft 3, a front end assembly of the box body 4, and a control system 5. The box body 1 is a shell structure as a whole, and the inside of the box body 1 Three earrings 11 for installing the hydraulic cylinder 2 are arranged side by side at the rear end of the box. The earrings 11 are provided with a hydraulic cylinder installation hole 12. The front end of the box body 1 is provided with a box semicircular seat 13 for installing the crankshaft 3. The box The body semicircular seat 13 is provided with a threaded hole connected with the box front end assembly 4; The internal hydraulic cylinder installation hole 12 is fixedly connected, and the hydraulic cylinder piston end 22 is connected to the crankshaft 3 through the piston end cover 23. The reciprocating motion of the hydraulic cylinder 2 drives the crankshaft 3 to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com