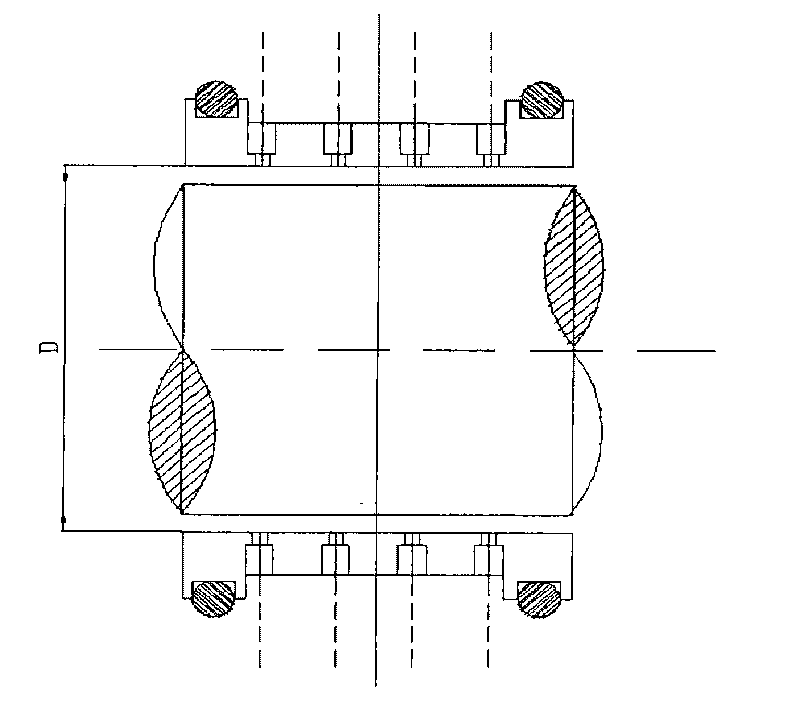

Dynamic and static pressure composite gas bearing with internal pi shaped air wedge groove

An air bearing, dynamic and static pressure technology, used in bearings, bearing components, shafts and bearings, etc., can solve problems such as instability, poor dynamic pressure effect of air bearings, and reduced bearing capacity of air bearings, so as to improve stability, The effect of reducing axial vibration and widening the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

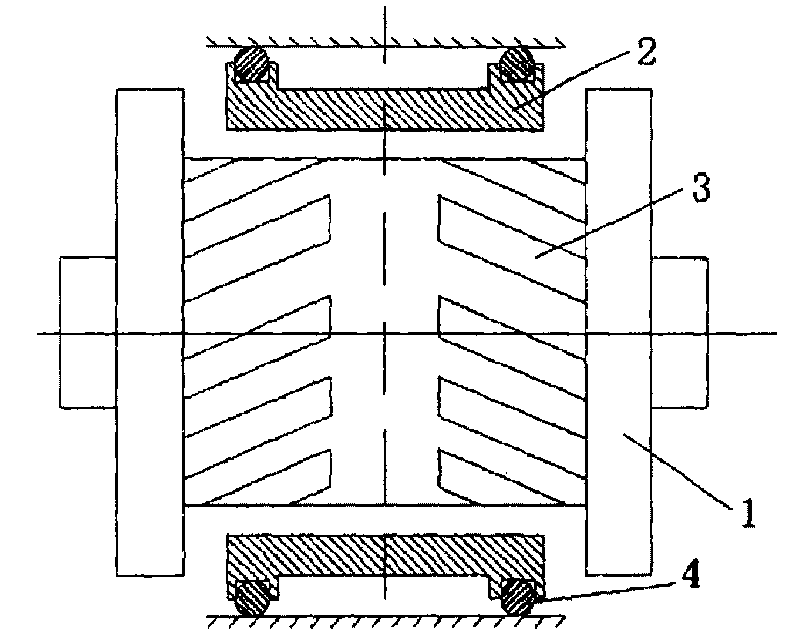

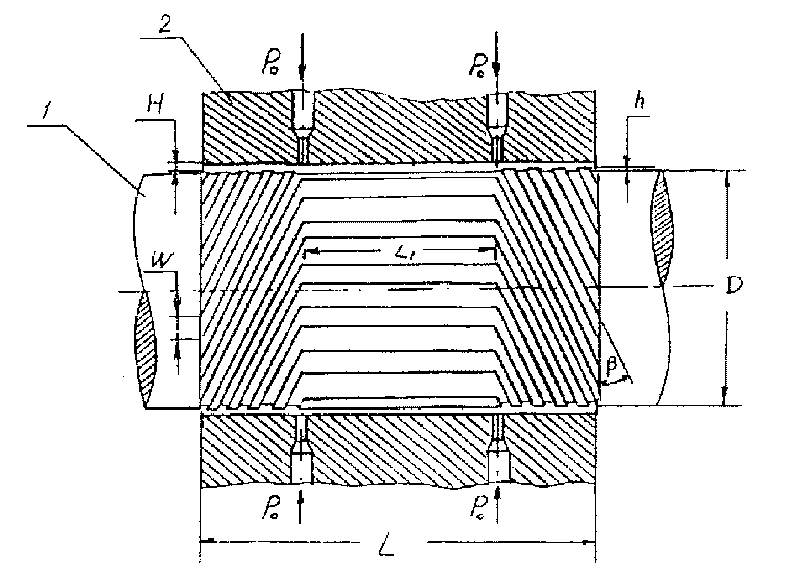

[0026] Embodiments are described in detail below in conjunction with technologies and accompanying drawings.

[0027] As shown in the figure, the inner π-shaped air wedge groove dynamic and static pressure composite air bearing of the present invention is composed of the static pressure air supply hole 01 on the thrust surface, the static pressure air supply hole 02 on the inner surface, the static pressure vertical nozzle 03 on the thrust surface, the inner surface It consists of static pressure tangential nozzle 04, inner surface dynamic pressure π-shaped air wedge groove 05, thrust surface dynamic pressure spiral groove 06, and sealing ring 07. The inner π-shaped air wedge groove dynamic and static pressure composite air bearing mainly provides support stiffness for the rotor journal through the static pressure system and the dynamic pressure system, among which,

[0028] The static pressure system includes thrust surface static pressure inlet hole 01, thrust surface static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com