Bearing component of molecular pump

A technology of bearing components and molecular pumps, which is applied to pump components, pumps, components of pumping devices for elastic fluids, etc., can solve problems such as large frictional heat, reduce friction, facilitate circulation and heat dissipation, reduce Effect of Axial Vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

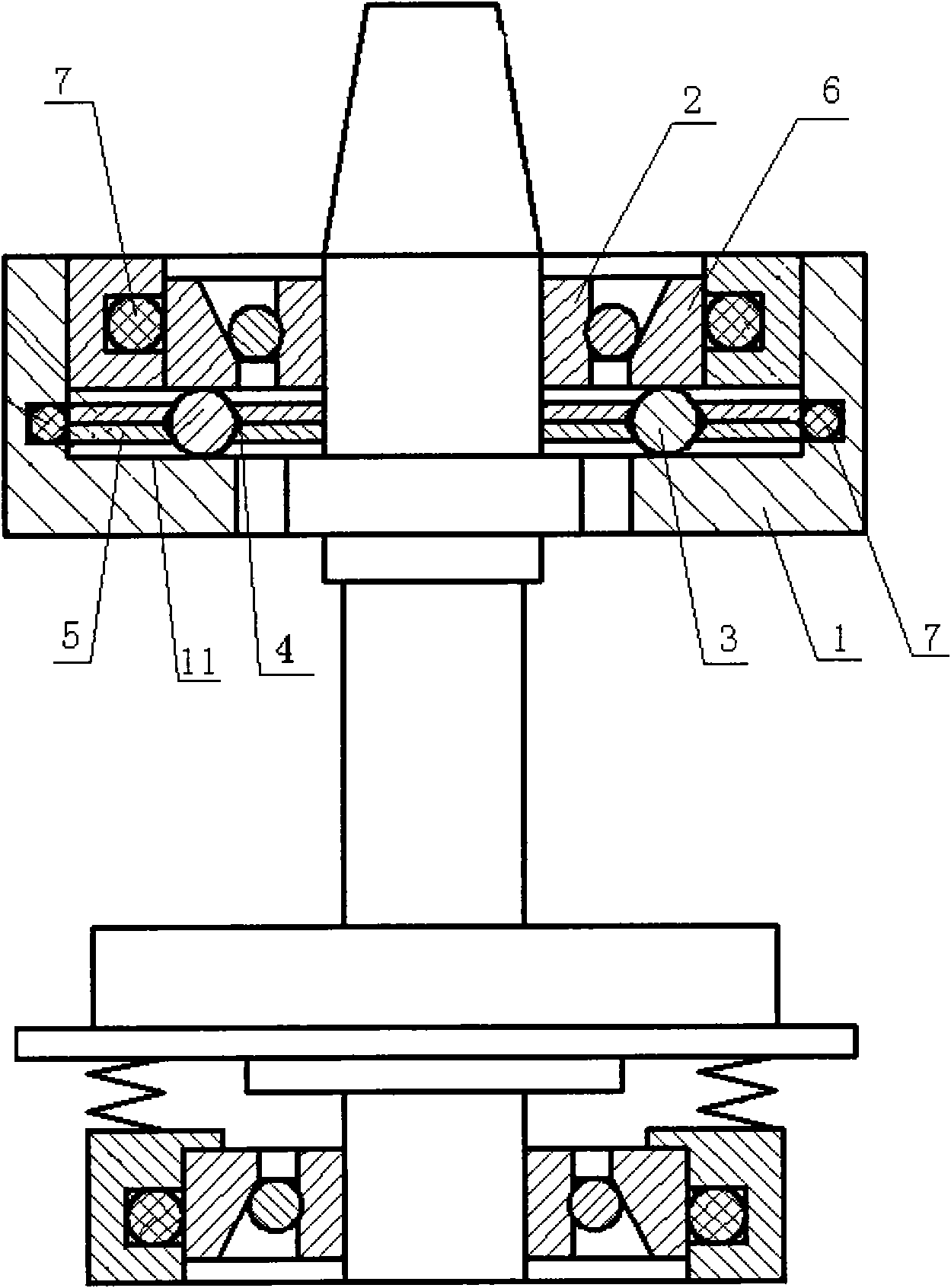

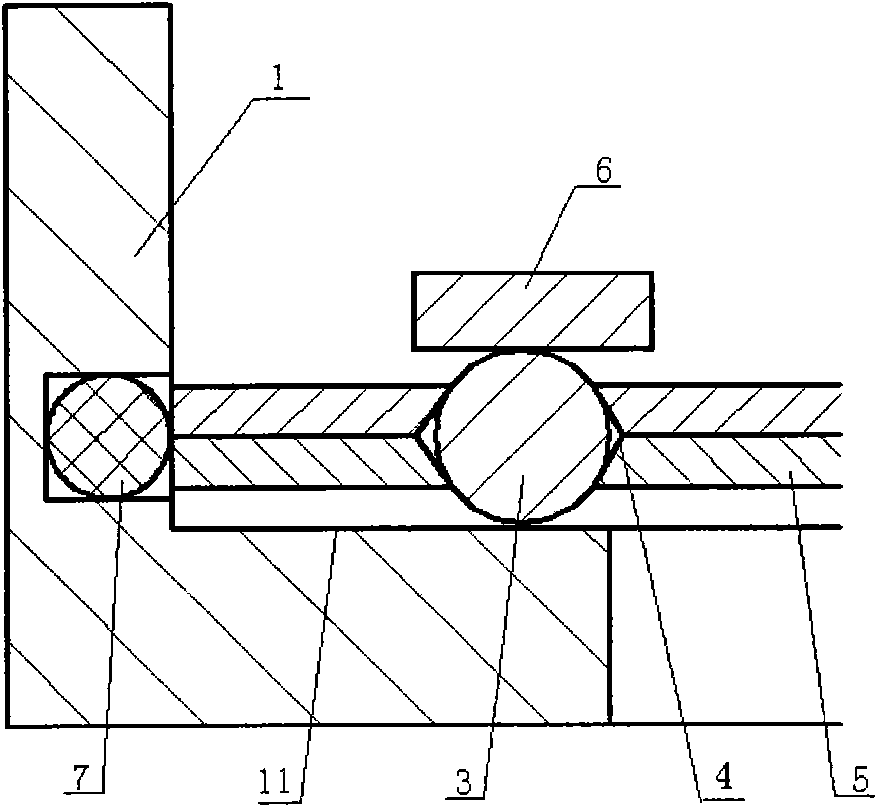

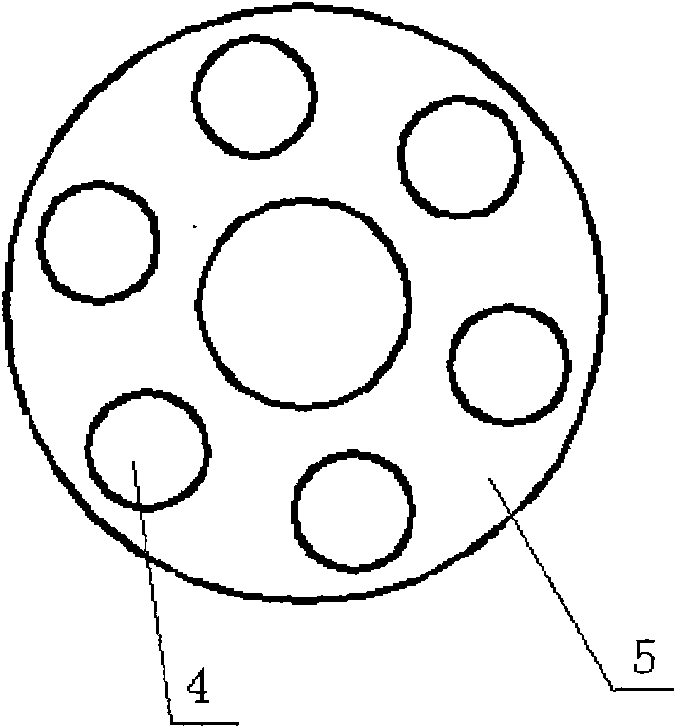

[0025] like Figure 1-3 As shown, the molecular pump bearing assembly of Embodiment 1 includes a bearing seat 1 having an axial positioning end face 11 and a bearing seat 1 that is used in cooperation with the bearing seat 1 and whose end face presses against the axial positioning end face 11 of the bearing seat 1. The bearing 2 is provided with several balls 3 between the bearing 2 and the axial positioning end surface 11 of the bearing housing 1 . The setting of the ball 3 can reduce the contact area between the bearing 2 and the end surface of the bearing seat 1, and the original annular contact surface becomes a point contact, which reduces friction and heat generation of the bearing 2, effectively protects the bearing 2 and can Extend the service life of the molecular pump. Moreover, since the contact surface between the bearing 2 and the end surface of the bearing seat 1 is reduced, the chance of grinding the lubricating oil on the contact surface is reduced, and the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com