Composite diamond drill bit with fixed buffer structure

A technology of diamond drill bit and buffer structure, applied in drill bits, drilling tools, drilling equipment, etc., can solve the problems of impact collapse or even brittle fracture, load state change, lateral vibration and other problems of PDC teeth outside the blade.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

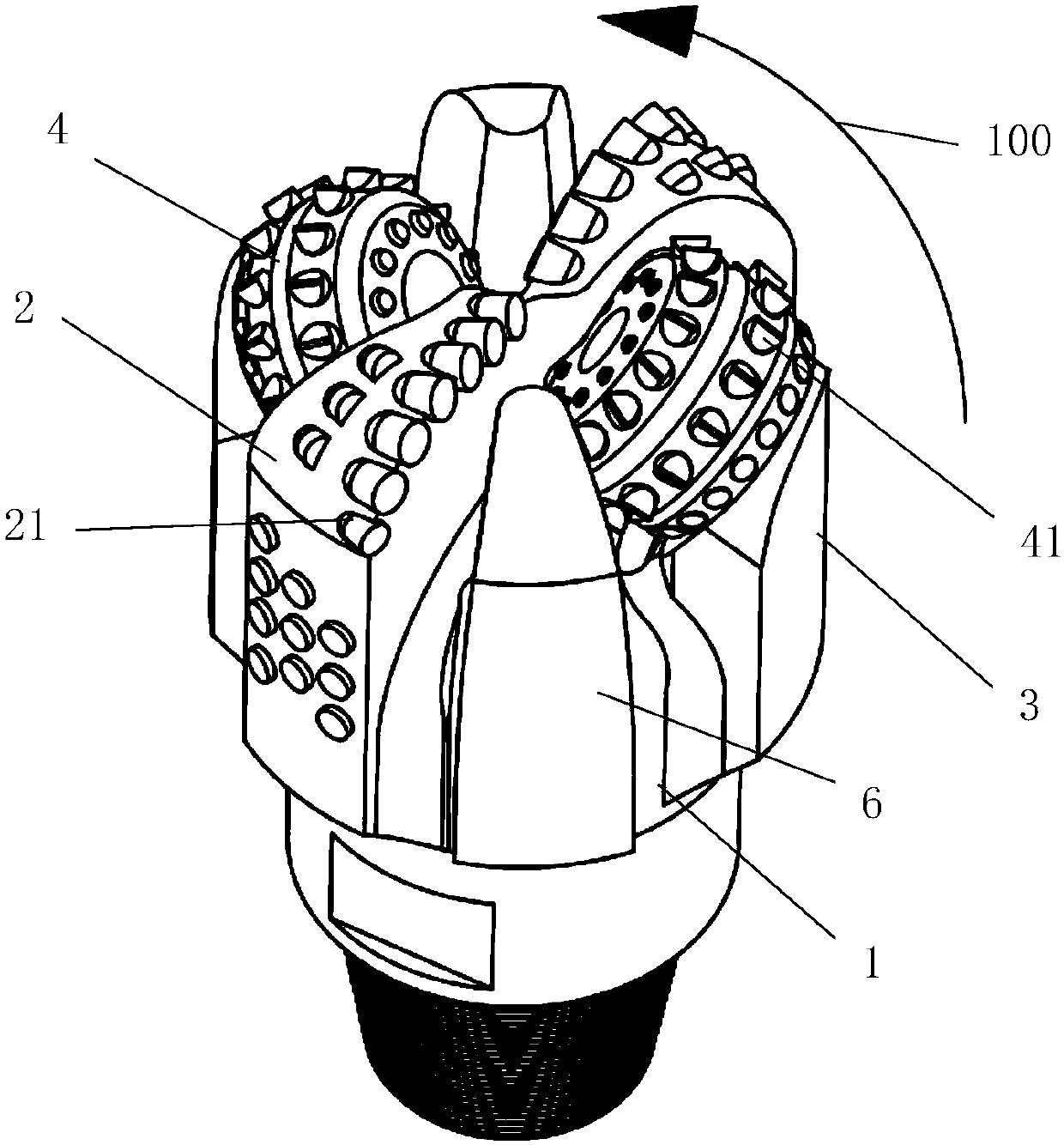

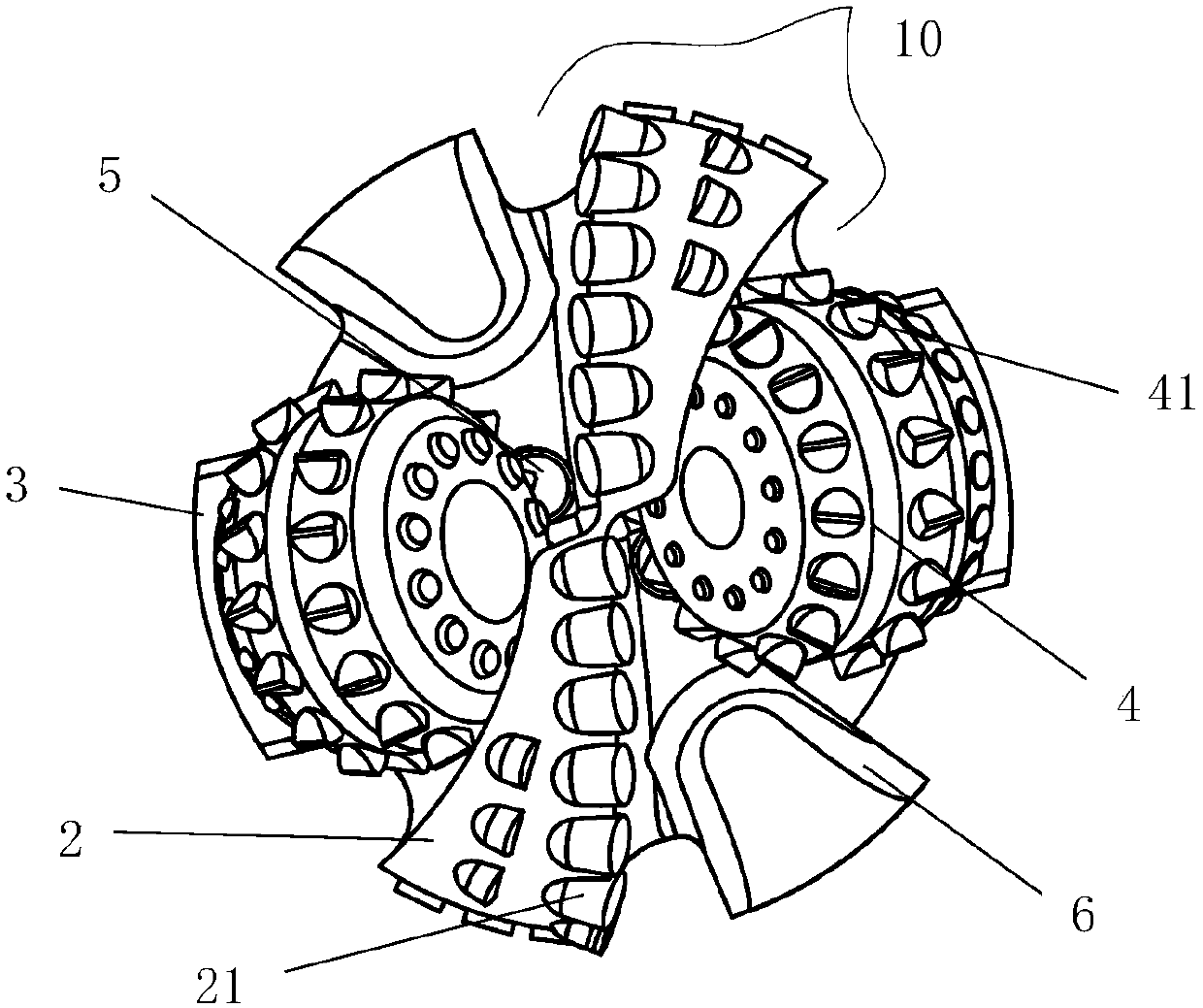

[0082] An embodiment of the present invention provides a composite diamond drill bit with a fixed buffer structure. see figure 1 and figure 2 , The drill bit includes a drill bit body 1, a blade 2, a cone consisting of two cone bodies 4 and teeth 41, a tooth palm 3, a water eye or a nozzle 5, and a buffer seat 6. The blade 2 extends from the drill body 1 or is fixed on the drill body 1 , and scraping teeth 21 are arranged on the blade 2 . A blade 2 is arranged between the front gear and the rear gear, and the buffer seat 6 is independently arranged between the front gear and the blade 2 following rotation.

[0083] see figure 1 , there are only two cones on the drill bit in this embodiment, and each cone can be either a front cone or a rear cone. When one cone is a front cone, the other cone is a rear cone. vice versa. More specifically, if in the drilling direction (item number 100), designate the cone on the palm marked 3 as the front cone, and the other cone following...

Embodiment 2

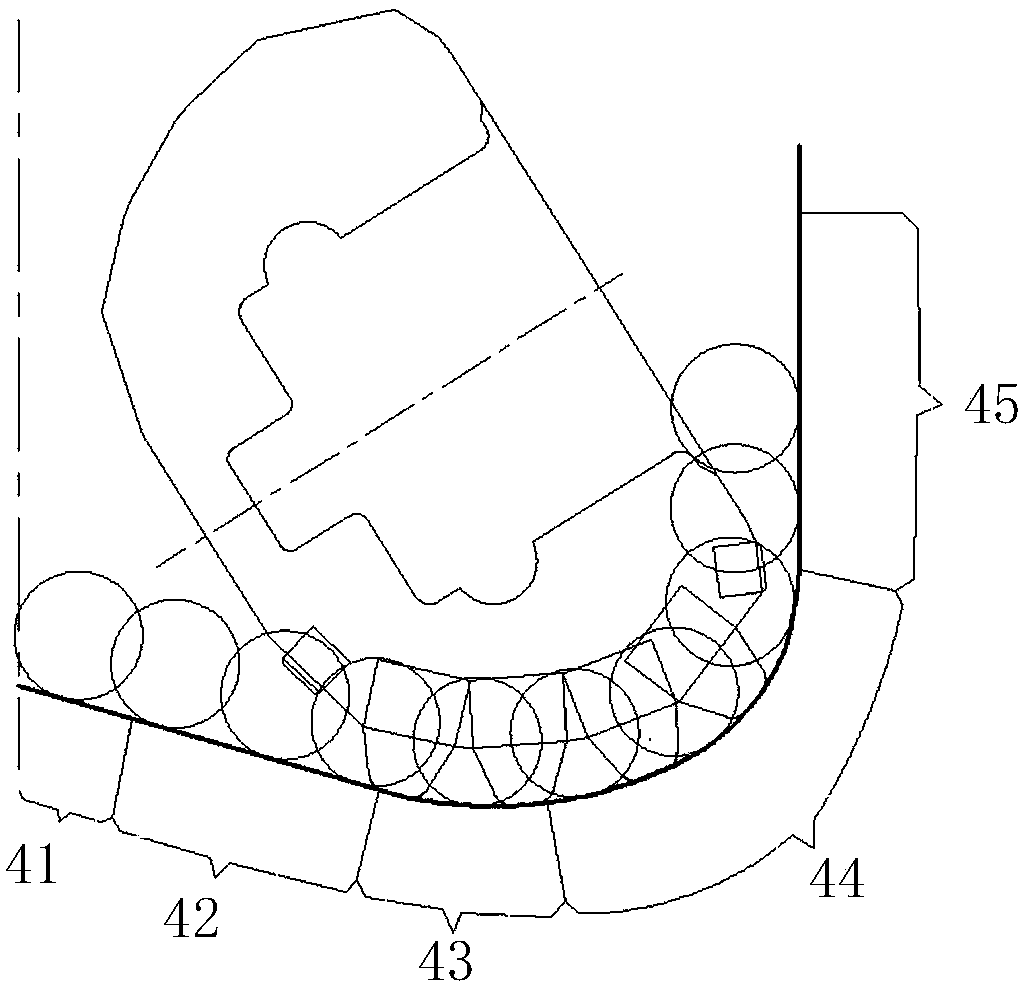

[0094] The embodiment of the present invention provides a composite drill bit suitable for directional drilling in hard formations. see Figure 14~17 , the drill bit includes a drill bit body 1, a blade 2, a cone consisting of two cone bodies 4 and teeth 41, a tooth palm 3, a water eye or a nozzle 5, and a buffer seat 6. The blade 2 extends from the drill body 1 or is fixed on the drill body 1 , and scraping teeth 21 are arranged on the blade 2 . A blade 2 is arranged between the front gear and the rear gear. The buffer seat 6 is independently arranged between the front toothed wheel and the first blade following its rotation. The working surface of the buffer seat 6 is provided with an accommodating groove 61 and a buffer element 7 , and the buffer element 7 is fixedly connected with the buffer seat 6 through the accommodating groove 61 . in, Figure 17 In the scheme, two blades are arranged between the front gear and the rear gear.

[0095] The cross-sectional shape of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com