Fixing device for optical fiber hydrophone

A fiber optic hydrophone and fixing device technology, which is applied in the direction of measuring devices, instruments, measuring vibration, etc., can solve the problem that the axial acceleration cannot be offset, and achieve the effect of improving the acoustic sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in conjunction with the accompanying drawings.

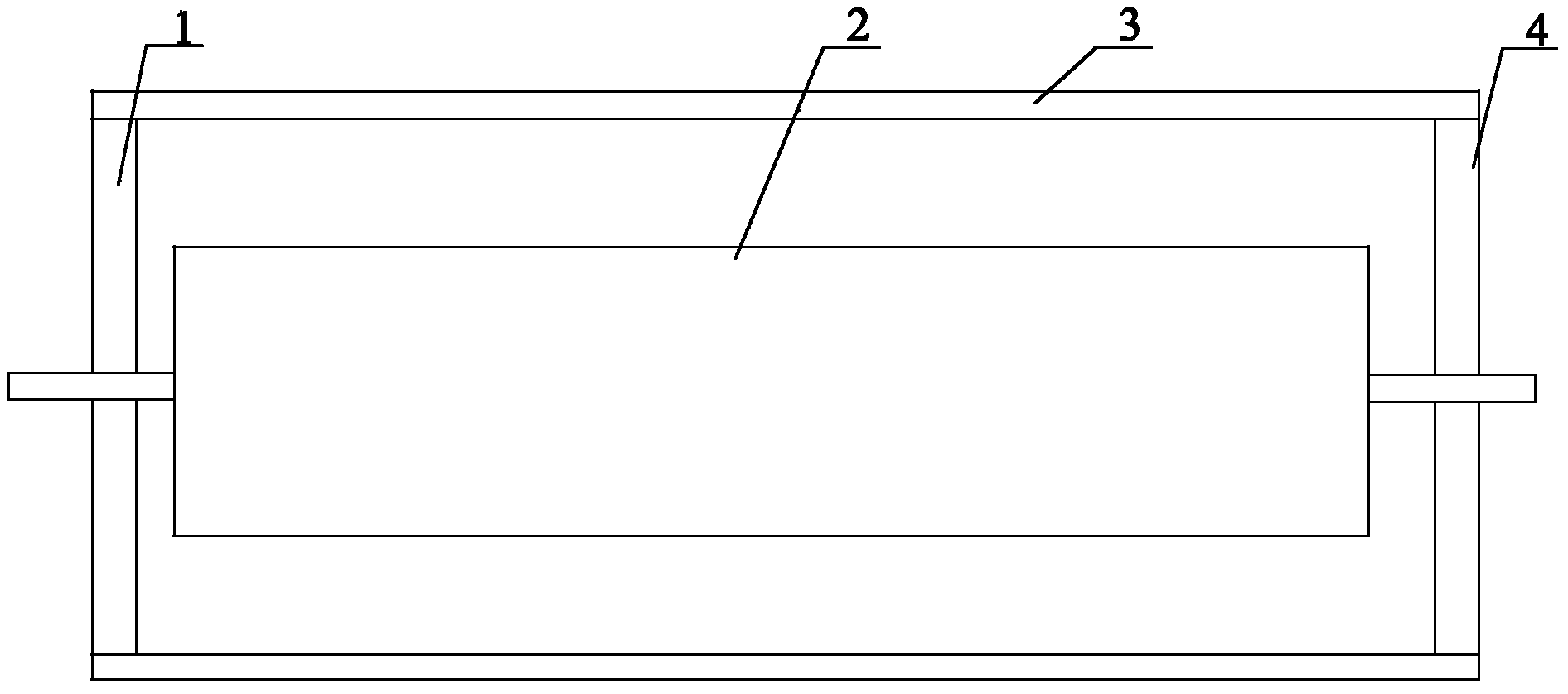

[0015] Such as figure 1 As shown, the present invention is made up of optical fiber hydrophone protective casing 3, front packaging part 1, rear packaging part 4, and front packaging part 1, rear packaging part 4 are respectively fixed behind the two ends of optical fiber hydrophone 2 , the front packaging part and the rear packaging part are respectively fixed on the pressure-resistant shell of the optical fiber hydrophone. The front packaging part 1 and the rear packaging part 4 are all cylindrical structural parts, which are composed of a rigid outer ring and an elastic inner ring. Both ends of the pressure-resistant housing 3 are fixed, and the elastic inner rings of the front packaging part 1 and the rear packaging part 4 are respectively fixed with the optical fiber hydrophone 2. The elastic inner ring in the front packaging part 1 and the rear packaging part 4 can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com