Method for reducing axial vibration of electric spindle of spinning machine

A technology of axial vibration and electromechanical ingot, which is applied in the direction of textiles and papermaking, can solve the problems of complex manufacturing process, rising use cost, high precision requirements, etc., and achieve the effect of enhancing stability, reducing axial vibration and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

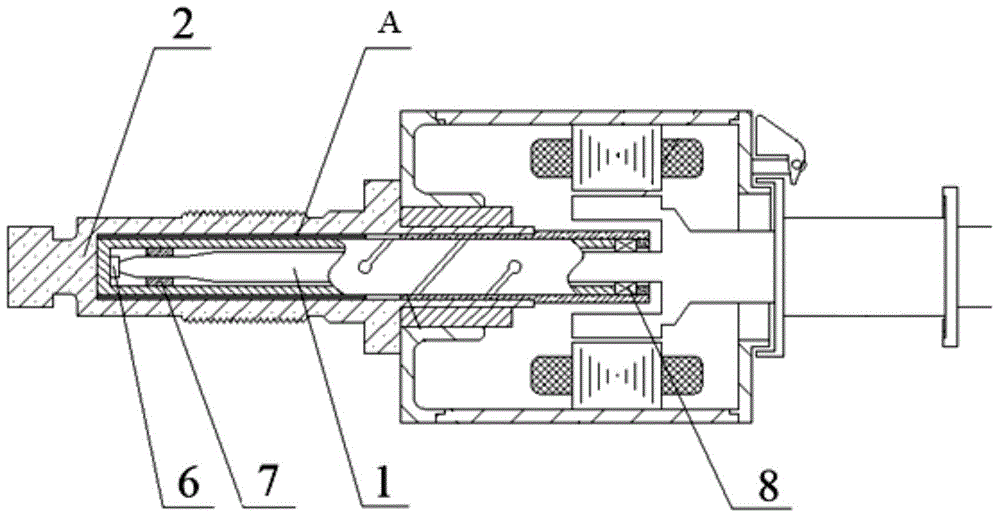

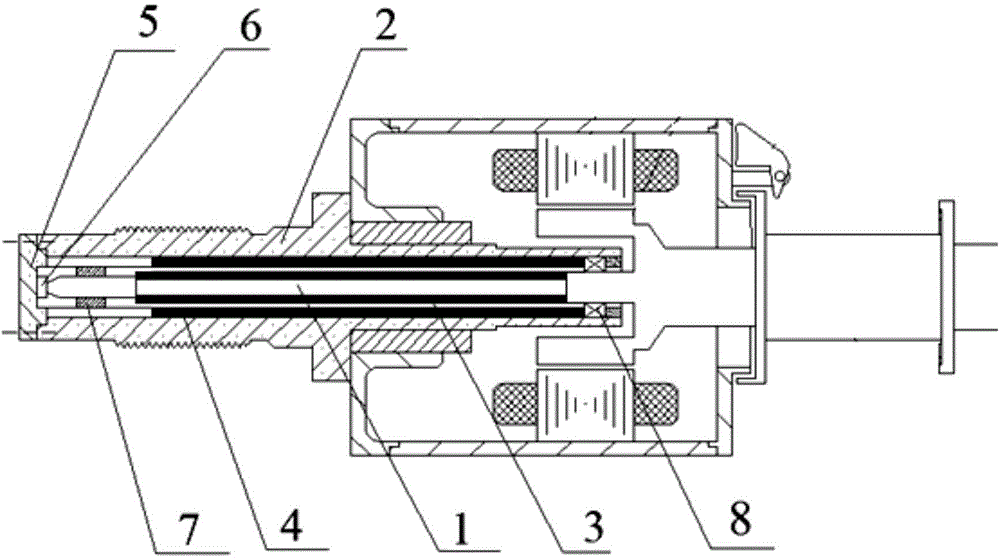

[0013] Example: A method for reducing axial vibration of the spinning machine spindle, figure 2 , image 3 It is the engineering diagram corresponding to this embodiment.

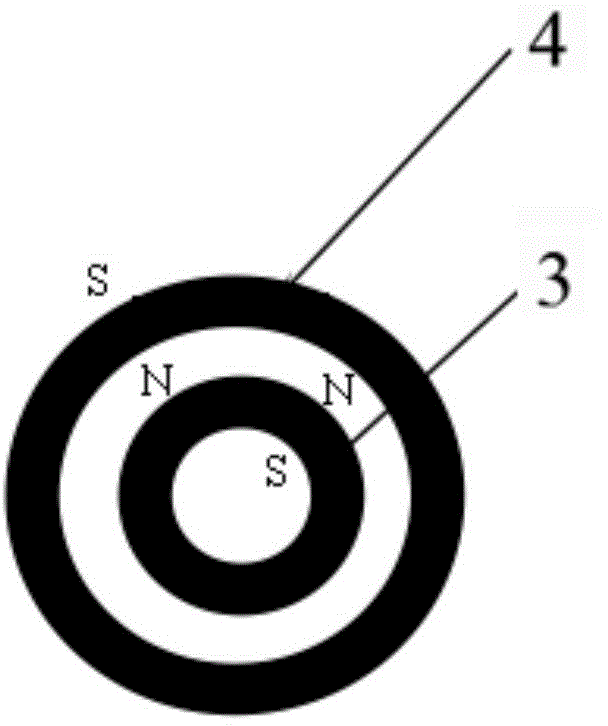

[0014] Among them, the stator part is to press the motor stator core containing the coil into the motor casing, and then cooperate them with the spindle foot 2 . For the rotor part, a needle bearing 8 is installed on the top of the spindle foot 2, a thrust bearing 6 is installed at the bottom of the spindle, and the tip of the spindle rod 1 is placed on the thrust bearing 6. The bottom of the ingot and the bottom end cover 5 are in one structure, and are connected with the ingot foot by screws. A sliding bearing 7 is provided between the tip of the spindle rod 1 and the spindle foot 2 for radial support. The motor rotor is placed inside the stator core, and the rotor core embedded with magnetic steel is aligned with the stator part; the outer middle part of the spindle bar 1 is inlaid with magnetic stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com