Ultra-thin strap combined forming rolling mill with different speed ratios capable of being adjusted online and continuously

A different speed ratio, ultra-thin strip technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of roll torsional vibration, high purchase, operation and maintenance costs, and transmission line length, etc. The effect of small roll torsional vibration, increasing the amount of thinning, and preventing belt breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

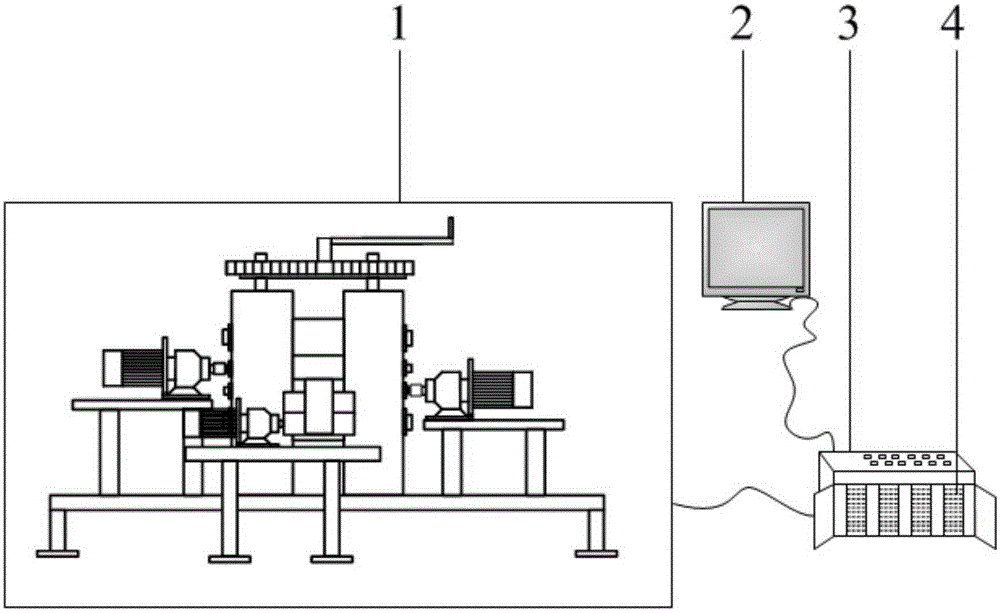

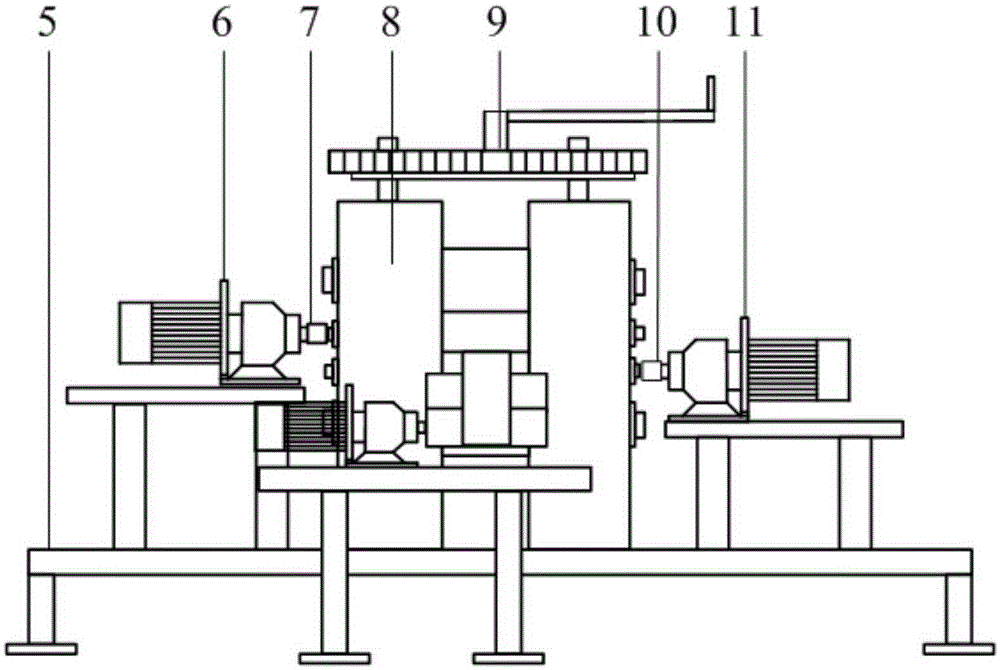

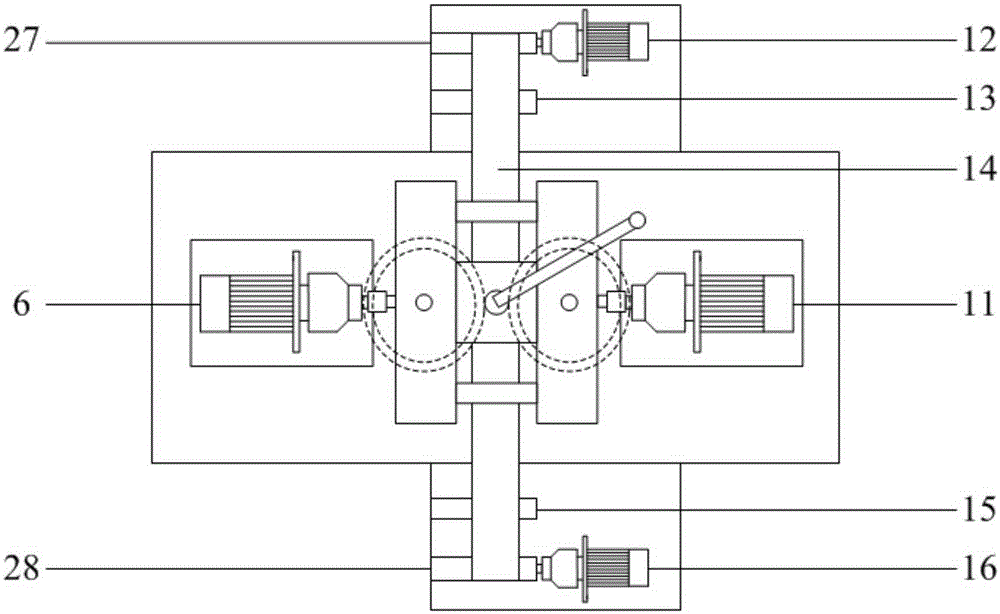

[0027] Such as Figure 1~5 As shown, an ultra-thin strip combined forming rolling mill with different speed ratios that can be continuously adjusted online includes a main control part of the rolling mill and a mechanical part of the rolling mill. The main control part of the rolling mill includes a main control computer 2, an operating console 3 and a PLC4. The mechanical part 1 of the rolling mill includes a base 5, a first main drive motor 6, a second main drive motor 11, an upper work roll 23, a lower work roll 25, an upper support roll 22, a lower support roll 26, a pressing device 9, and an archway 8 , the first tension motor 12 and the second tension motor 16;

[0028] The man-machine interface of the rolling mill control system is provided in the main control computer 2, and the speed setting input and output domains of the u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com