High-rigidity transmission mechanism

A transmission mechanism, high rigidity technology, applied in transmission devices, mechanical equipment, belts/chains/gears, etc., to achieve the effect of high transmission rigidity, improved rigidity, and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

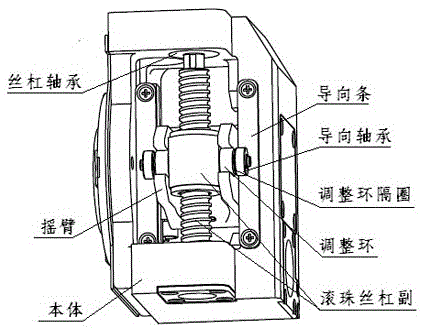

[0017] Such as figure 1 Shown is a high-rigidity transmission mechanism, which is composed of a body, a screw bearing, a ball screw pair (including a ball screw and a ball nut), a rocker arm, an adjusting ring, an adjusting ring spacer, a guide bearing, and a guide bar.

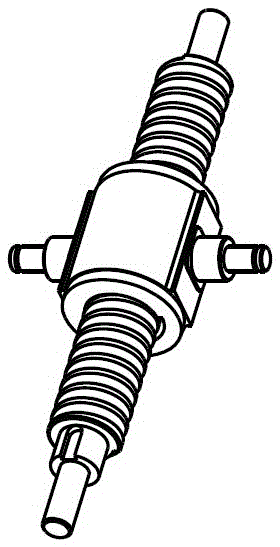

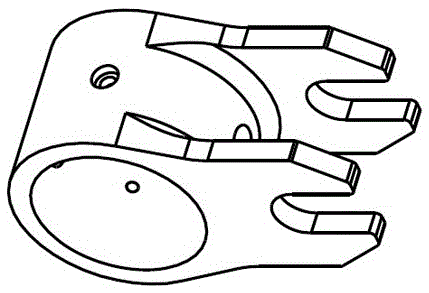

[0018] Figure 2-5 It is a schematic diagram of the structure of the ball screw pair, the rocker arm, the adjustment ring and the guide bar.

[0019] Such as figure 1 As shown, the ball screw makes a circular motion. Due to the existence of the guide bearing during the motion, the ball nut can only move up and down. The translation is transformed into the circular motion of the rocker arm. The ball screw is fixed on the body through the screw bearings at both ends. In order to improve the bearing capacity, the screw bearing adopts double-row deep groove ball bearings; a support arm protrudes from each end of the ball nut, and the cylindrical section of the support arm is connected with the adjustment ring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com