Multifunctional rolling mill for producing thin metal straps and ultra-thin metal straps

An ultra-thin strip and multi-functional technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of high cost, difficult rolling of liquid, powder and granular metal raw materials, non-changeable disassembly And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

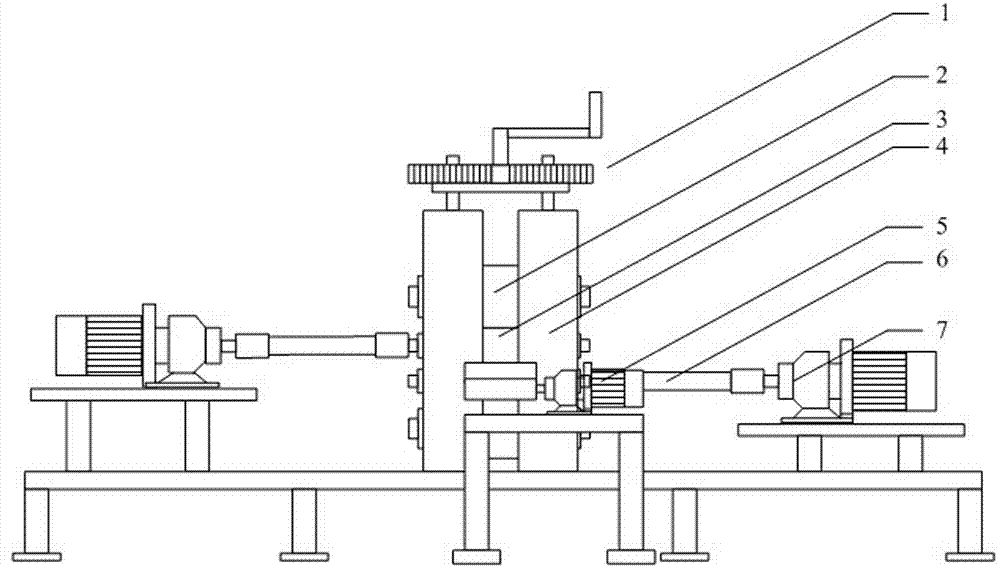

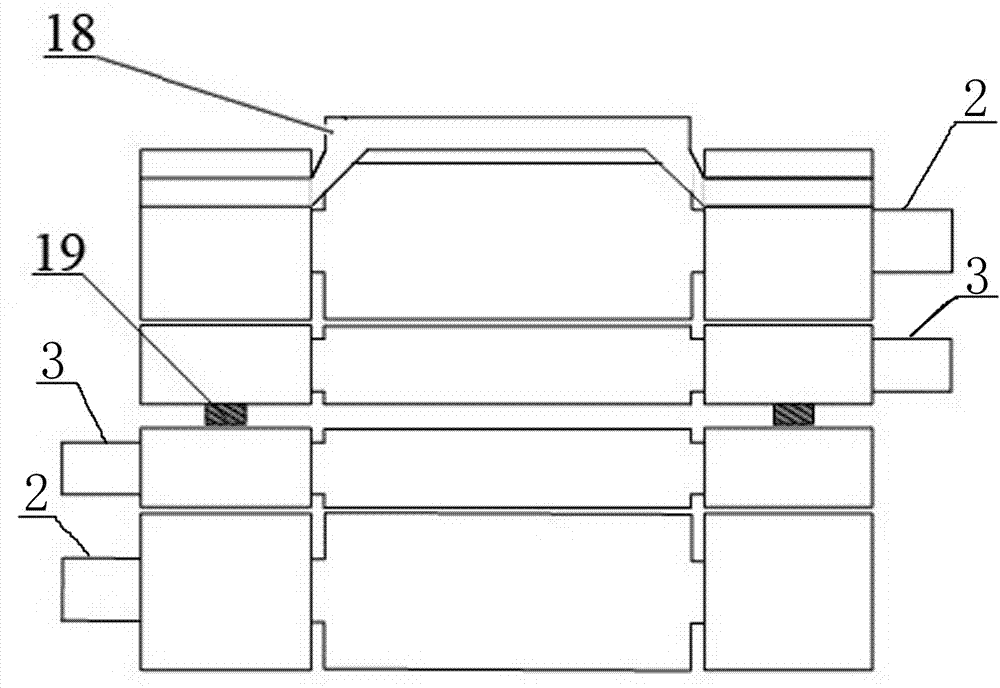

[0052] The four-roller vertical distribution rolling mill includes a pressing device 1, a pair of vertically distributed work rolls 3 and a pair of support rolls 2, a archway 4 and a base 10, a tension motor 5, a main drive motor 7, a drum 8 and a tension roll 9. The archway 4 is fixed on the base 10 by bolts on the contact surface 15 between the archway and the base in a vertical arrangement. Both ends of the roll are fixed by sliding bearing seats, and the roll and bearing seats move at the same time. The bearing seats of the upper backup roll 2 are balanced by The beam 18 is hoisted, the bearing seat of the lower back-up roll 2 is fixed at the bottom of the archway 4, the bearing seats of the upper and lower work rolls 3 are connected by a spring 19 between the work rolls, and the upper surface of the bearing seat of the lower work roll 3 has holes and grooves, so that the springs between the work rolls 19 is fixed inside, the upper end of the spring 19 between the work roll...

Embodiment 2

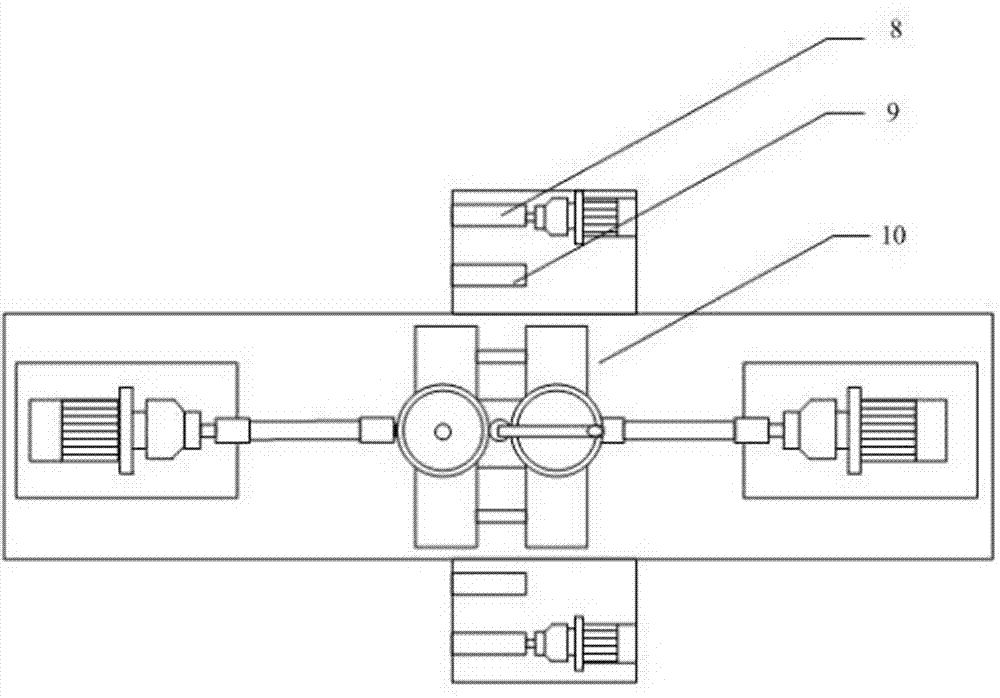

[0056] The two-roll horizontally arranged rolling mill is composed of two work rolls 3 arranged horizontally on the left and right, the archway 4 and the base 10, the main drive motor 7, the feeding port 11 and the discharge port 12, and the archway 4 passes through the two-roller horizontally arranged archway. The contact surface 14 with the base is fixed on the base 10 by bolts. The work rolls 3 are the work rolls 3 in the four-roll vertical arrangement after disassembly, and the backup rolls 2 in the four-roll vertical arrangement are used as the work rolls 3 in the two-roll horizontal arrangement.

[0057] Start the power supply of the rolling mill system. During rolling, liquid, powder or particles are sent into the roll gap through the feeding port, and the finished strip is obtained after rolling.

Embodiment 3

[0059] The two-roll vertically arranged rolling mill is composed of a pressing device 1, a pair of vertically distributed work rolls 3, an archway 4 and a base 10, a tension motor 5, a main drive motor 7, a reel 8 and a tension roll 9; The work roll 3 is the work roll 3 of the four-roll vertical arrangement after disassembly, and the backup roll 2 in the four-roll vertical arrangement is used as the work roll 3 in the two-roll vertical arrangement. The archway 4 is vertically arranged The arch and the base contact surface 15 are fixed on the base 10 by bolts.

[0060] Start the power supply of the rolling mill system, and carry out synchronous or asynchronous rolling and forming of the thin strip billet. The rolling process is carried out under the condition of strip tension. After multiple passes of repeated rolling, the thickness range is below 0.05mm, until it is below 0.005mm. Finished functional material for thin strips.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com