Rapid pineapple harvester

A picking machine and pineapple technology, which is applied in the field of fast pineapple picking machines, can solve problems such as low accuracy, high environmental requirements, and high manual labor intensity, and achieve good precision retention, sensitive and stable transmission, and simple and reliable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

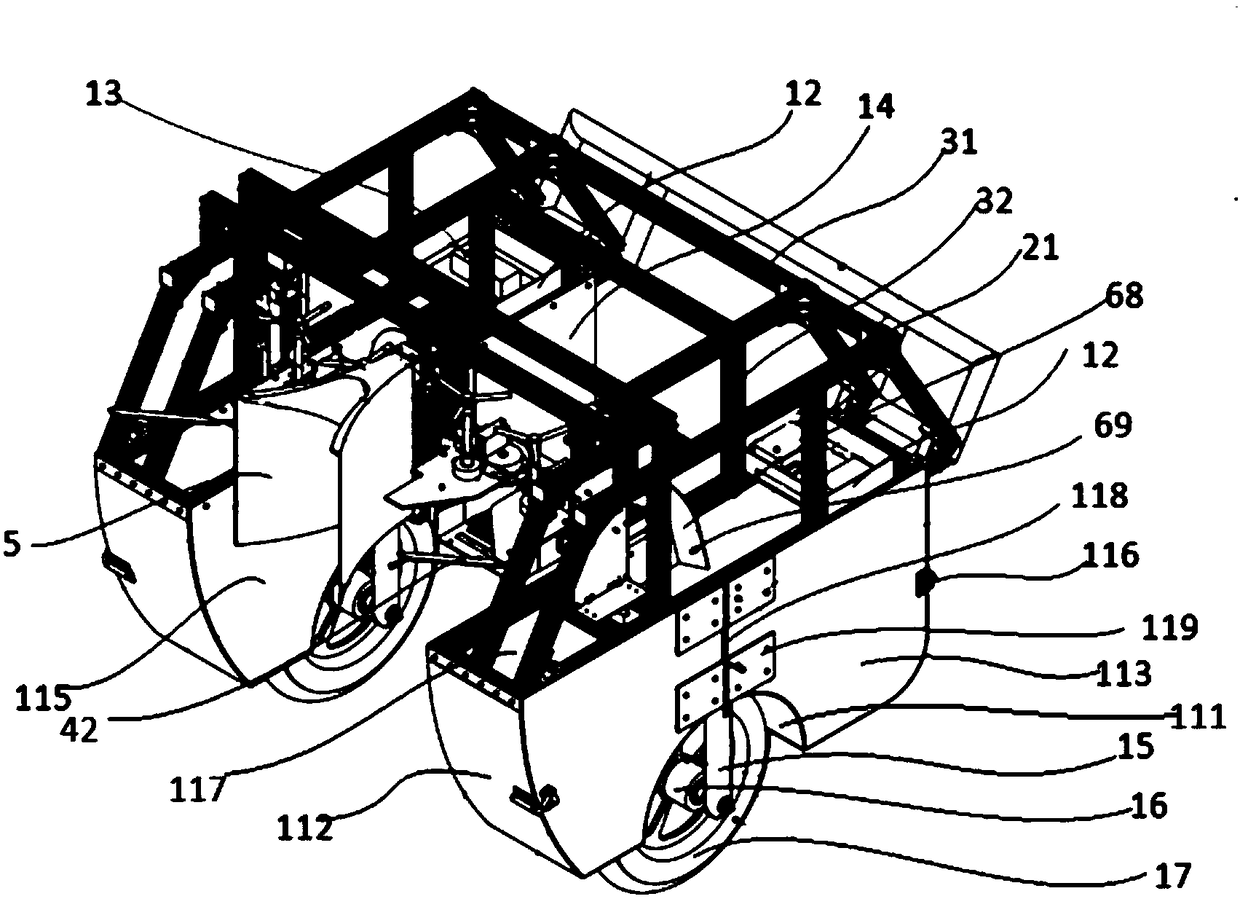

[0075] A fast pineapple picking machine mainly includes the following modules:

[0076] Collecting module I1, collecting module II2, connecting module 3, shearing module 4, leaf pressing block 5 and lifting mechanism 6.

[0077] The collection module I1 mainly includes a collection box 11 , an installation box 12 , a storage battery 13 , an LED display 14 , a wheel frame 15 , an axle 16 and wheels 17 .

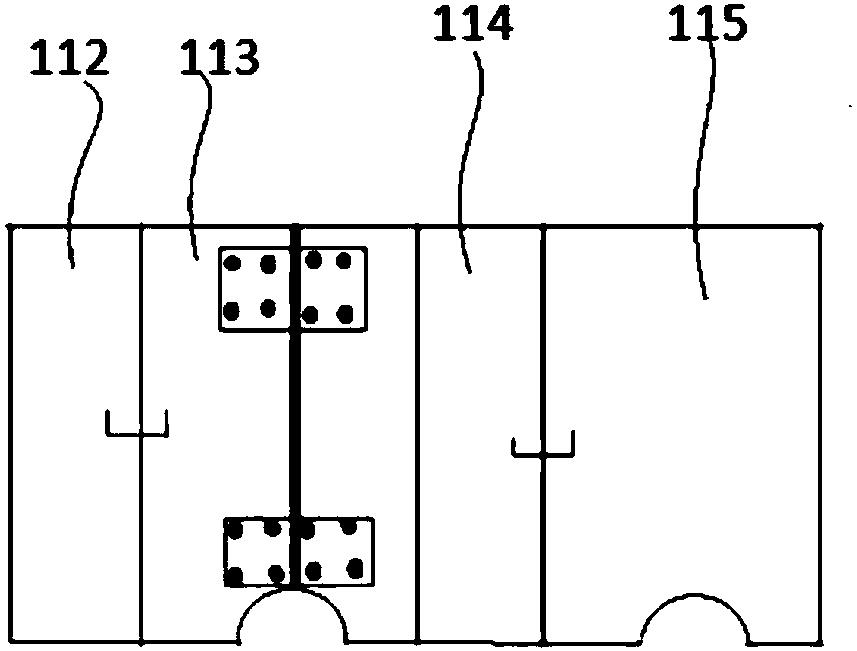

[0078] The collection box 11 mainly includes a groove 111 , an A side 112 , a B side 113 , a C side 114 , a D side 115 , a door handle 116 , a collection frame 117 , a pin 118 and a hinge piece 118 .

[0079] The top of the collection box 11 is open. The bottom of the collection box 11 has the groove 111 . The shape of the groove 111 matches the shape of the wheel 14 .

[0080] The collection box 11 includes four sides, namely A side 112 , B side 113 , C side 114 and D side 115 .

[0081] The side B 113 is a side door.

[0082] The vertical pin 118 is welded in the middle...

Embodiment 2

[0141] A method for using a fast pineapple picking machine mainly includes the following steps:

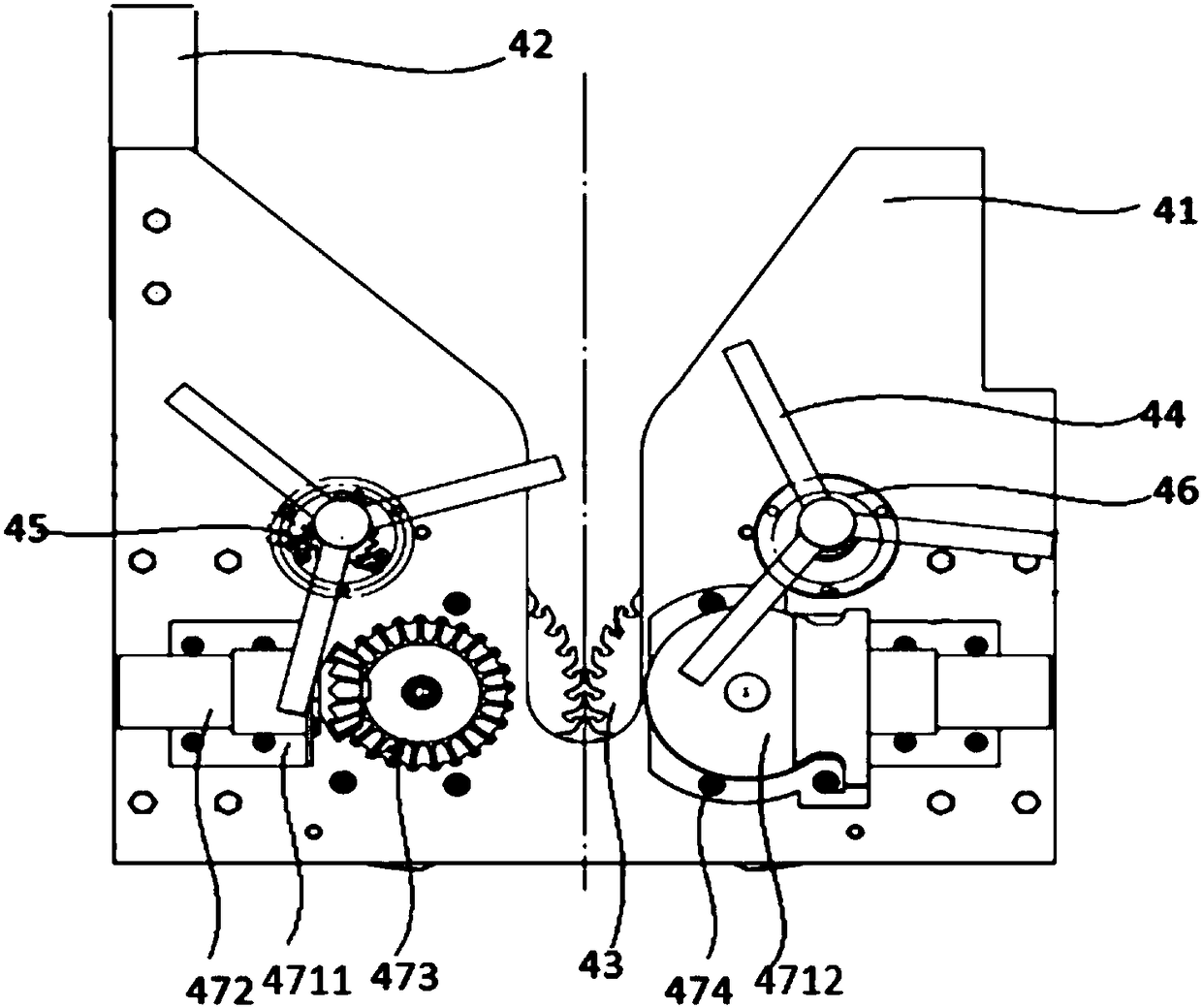

[0142] 1) Assemble the Quick Pineapple Picker. Wherein, the motor I472 and the motor II61 are DC motors, and the maximum power is set to 80W. The torque of the motor I472 is 1.8N·m. The minimum torque of the cemented carbide saw blade 43 is 30N, and the speed n ranges from 600 to 2000rpm.

[0143] 2) Put the fast pineapple picker in the pineapple field.

[0144] 3) When picking pineapple, the pressing blade 42 and the leaf pressing block 5 press the pineapple blade under the cemented carbide saw blade 43 .

[0145] 4) The pineapple reaches the hard alloy circular saw blade 43 through the tripod 44 through the automatic guiding effect of the picking front plate 41 .

[0146] 5) According to the height of the pineapple plant and the topography of the pineapple field, the lifting mechanism 6 adjusts the height of the cutting module 4, so that the hard alloy circular saw blade 43 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com