Dual-purpose main shaft in Electric Discharge Machining machine tool

A technology for EDM machine tools and spindles, which is used in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large motion inertia, limited linear speed, acceleration and positioning accuracy, heavy tasks, etc., to expand the processing range, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and in the form of embodiments.

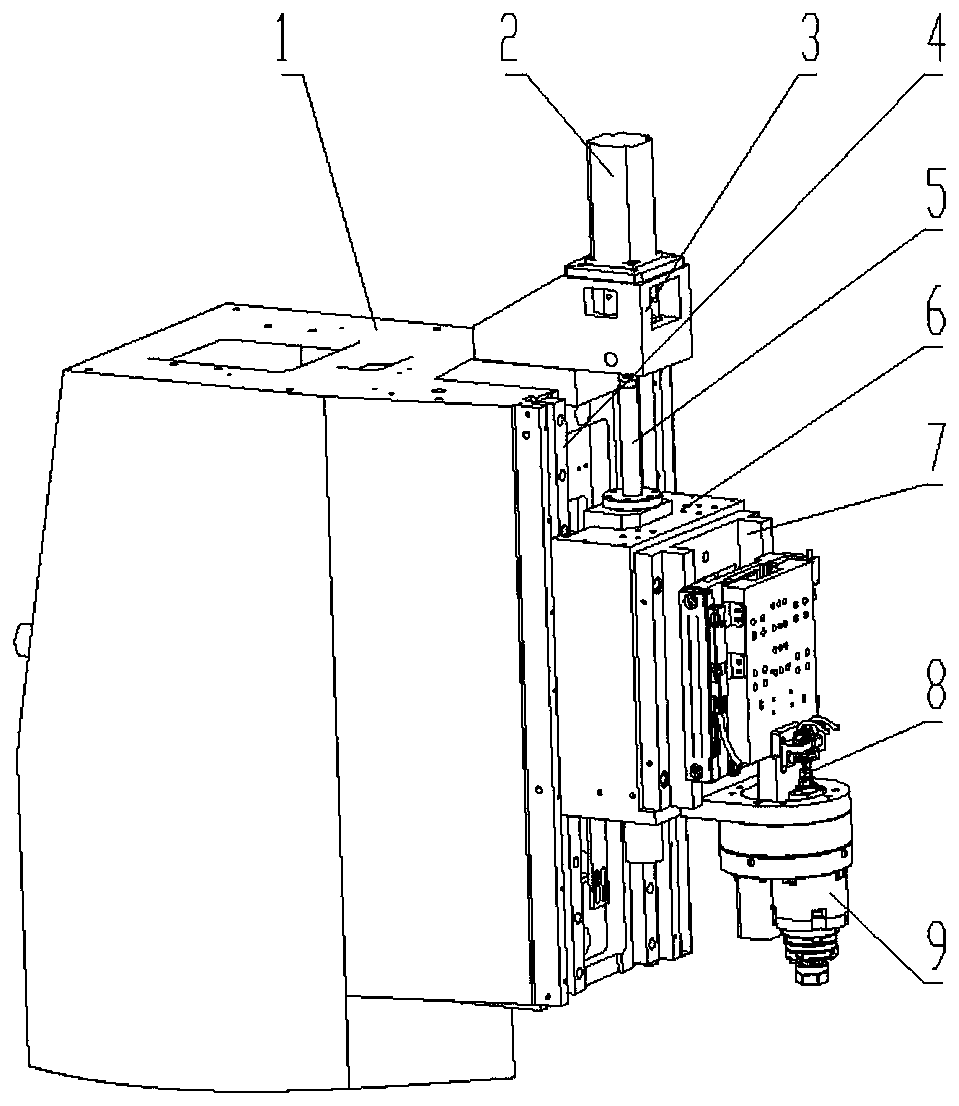

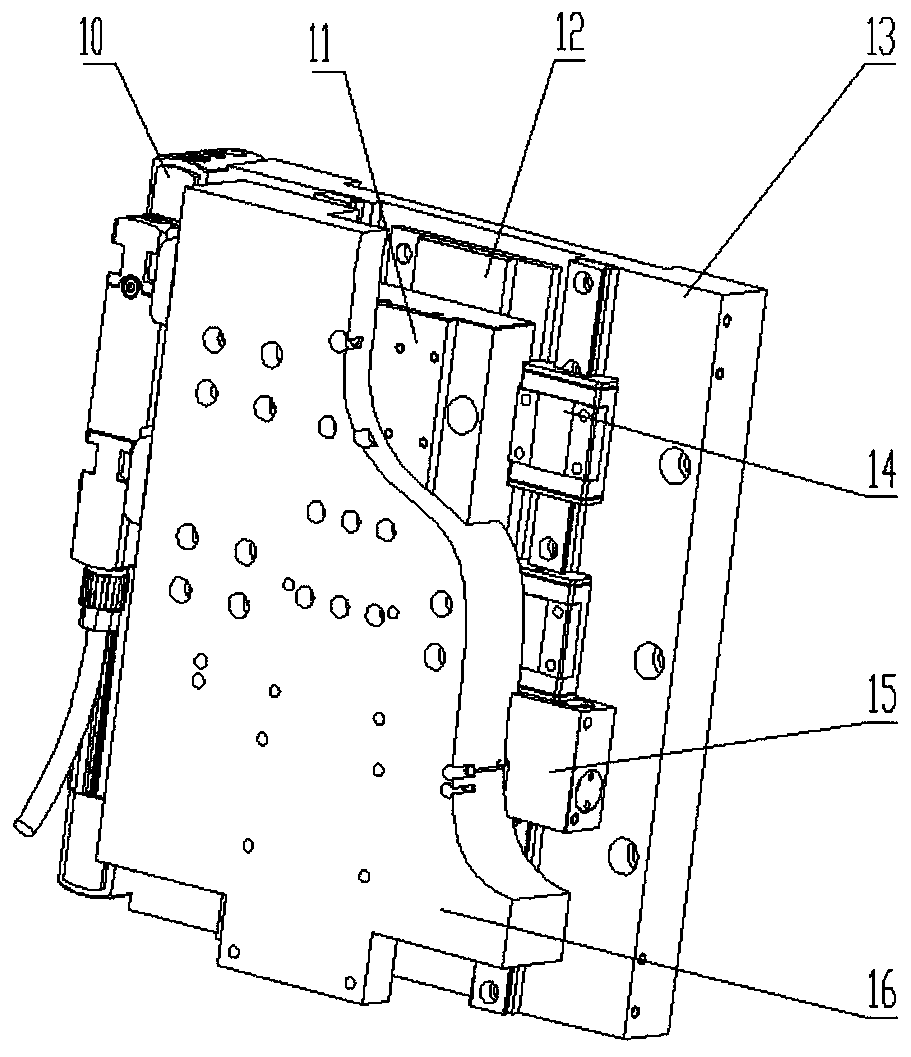

[0025] Such as Figure 1-Figure 2 As shown, a dual-purpose spindle in an EDM machine tool includes a spindle system, namely the Z system, and a linear motor system, namely the W system;

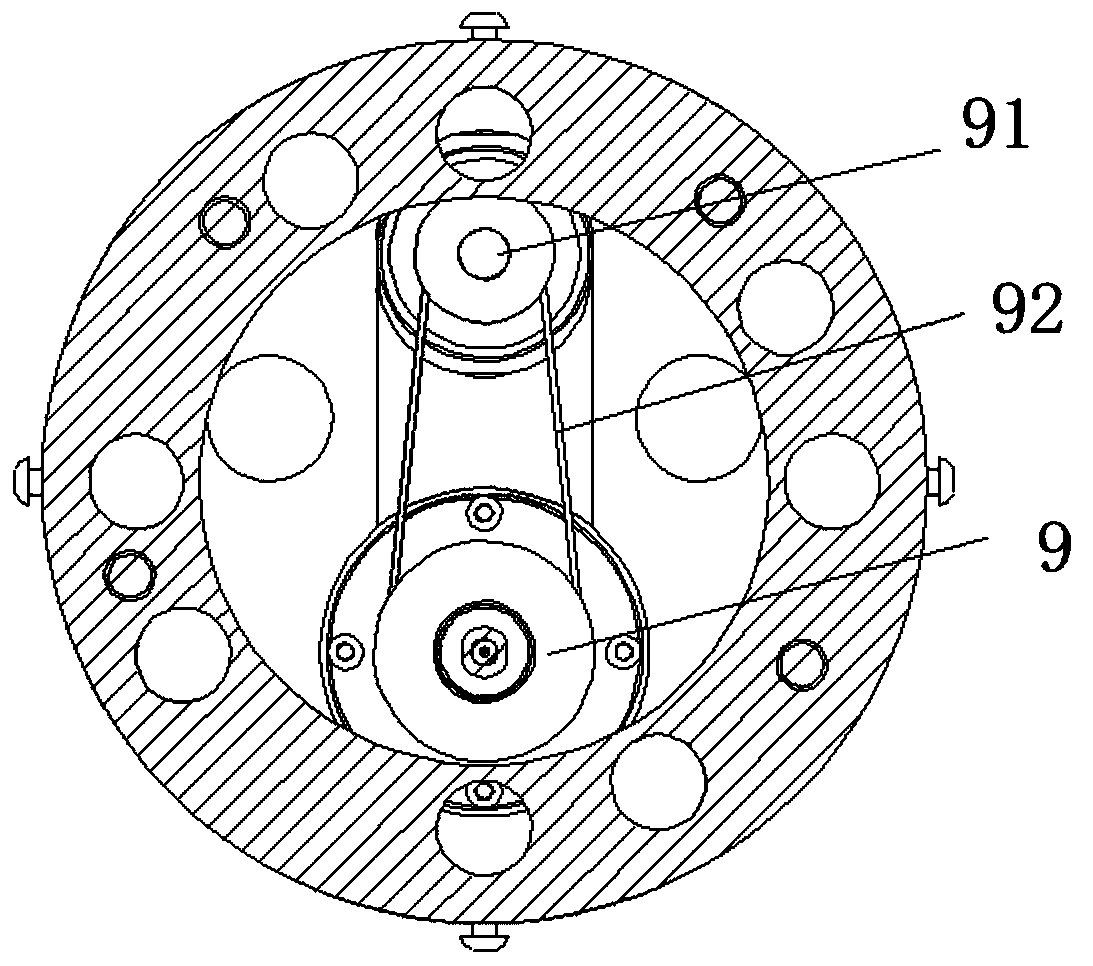

[0026] The spindle system is set on the column 1 of the EDM machine tool, including the Z-axis servo motor 2, the ball screw 5, the Z-axis slide seat 6 and the R-axis 9, and the Z-axis servo motor 2 is fixed on the column 1 through the motor bearing seat 3. Specifically, the Z-axis servo motor 2 is fixed on the motor bearing seat 3 through bolts, and the Z-axis servo motor 2 is connected with the Z-axis ball screw 5 through a coupling. The Z-axis servo motor 2 drives the Z-axis ball screw 5 to rotate so as to drive the Z-axis sliding seat 6 to move up and down, and the R-axis 9 is fixed on the R-axis bracket fixedly connected to the lower part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com