Multistage-transmission speed-reduction clearance-elimination gear box for airplanes and clearance-elimination method

A technology of gearboxes and driven gears, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve problems such as large gaps and large nonlinear manipulation, and achieve the effects of saving space and strong transmission stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

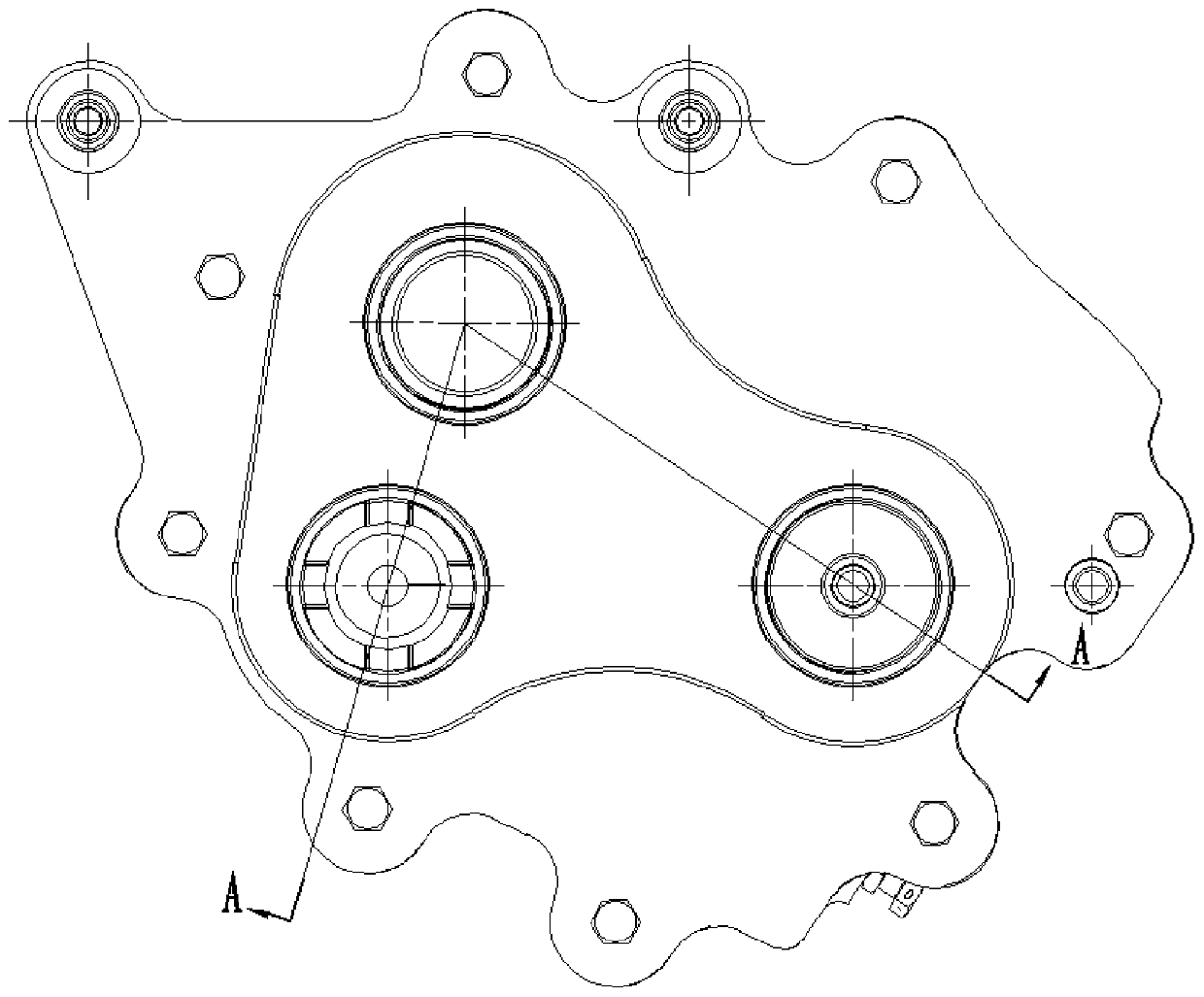

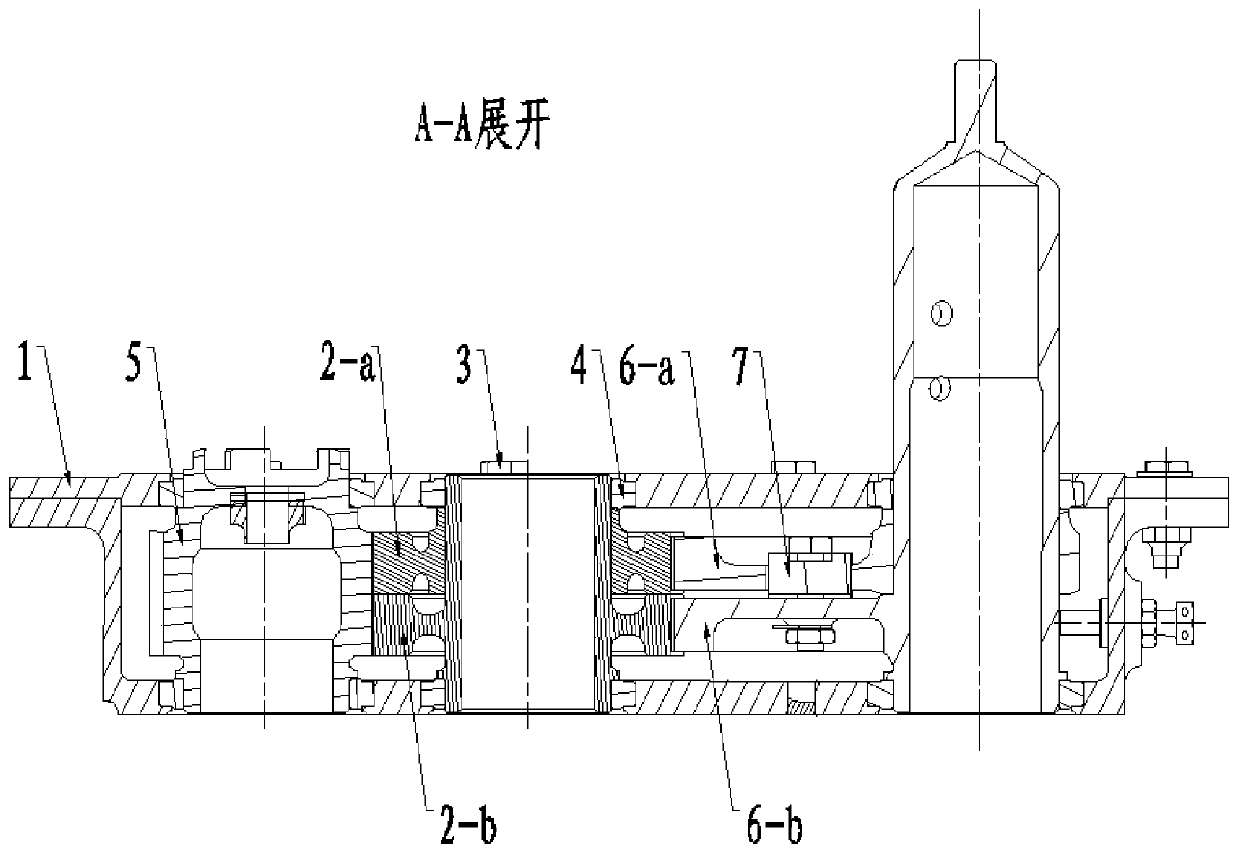

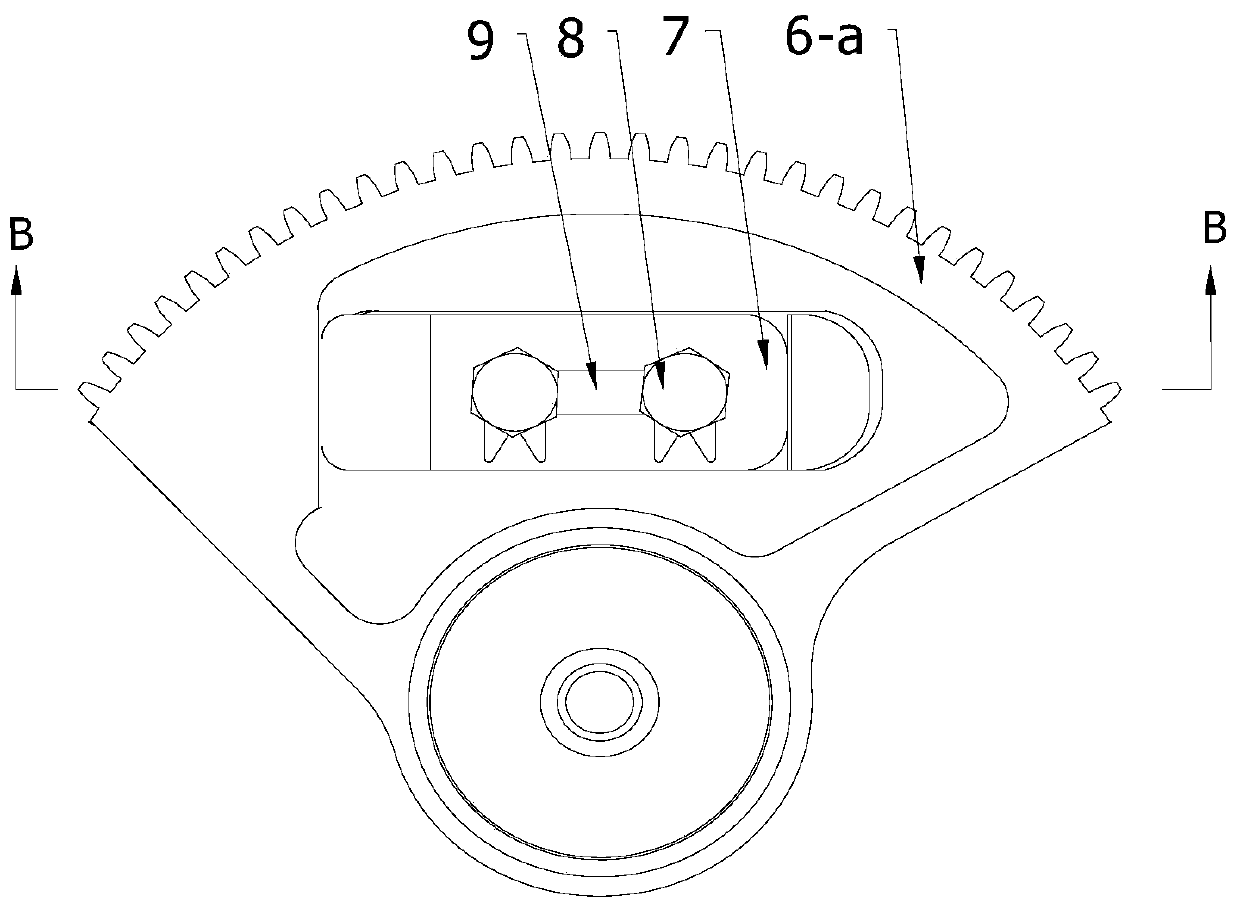

[0040] like figure 1 and figure 2 As shown, the present invention is a multi-stage transmission deceleration anti-backlash gear box for aircraft, comprising driving gear 5, intermediate gear set, driven gear set, gear box body 1, deep groove ball bearing 4, first hexagon head bolt 3. Anti-backlash block 7. The driven gear set includes: driven gear thin gear 6-a and driven gear thin gear shaft 6-b; the intermediate gear set includes: intermediate gear thin gear 2-a and intermediate gear thin gear shaft 2-b; driving gear 5 , the intermediate gear set and the driven gear set are arranged inside the gear box body 1, the driving gear 5 meshes with the intermediate gear set, and the intermediate gear set meshes with the driven gear set. The driving gear is a thick gear, and the intermediate gear set and the driven gear set are composed of two thin gears with the same number of teeth and tooth width. The tooth width of the thin gear is about 1 / 2 of the tooth width of the thick gea...

Embodiment 2

[0044] A two-stage transmission anti-backlash gear compensation mechanism for aircraft: the driving gear 5 is a thick gear with a tooth width of 30 mm, the intermediate gear set is composed of two thin gears with the same number of teeth, and the tooth width is 15 mm, and the driven gear set is composed of two thin gears with the same number of teeth. Composed of two thin gears, the tooth width is 13mm; the driving gear 5 is a one-piece spur gear, the driving gear 5 meshes with the intermediate gear set, and the intermediate gear set meshes with the driven gear set. One of the thin gears is set on the shaft integrated with the other thin gear, and can perform relative rotation. The driven gear thin gear 6-a and the driven gear thin gear shaft 6-b of the driven gear set are sector gears . A piece of thin gear in the driven gear set has a rectangular notch in the hub web, the rectangular notch is vertically and radially arranged in the middle of the web, one side of the rectangu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com