Nutation oscillating-tooth speed reducer

A movable tooth deceleration and movable tooth technology, applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of low transmission efficiency, low bearing capacity, complex structure, etc., achieve high bearing capacity, reduce the number of parts, The effect of reducing the size of the mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

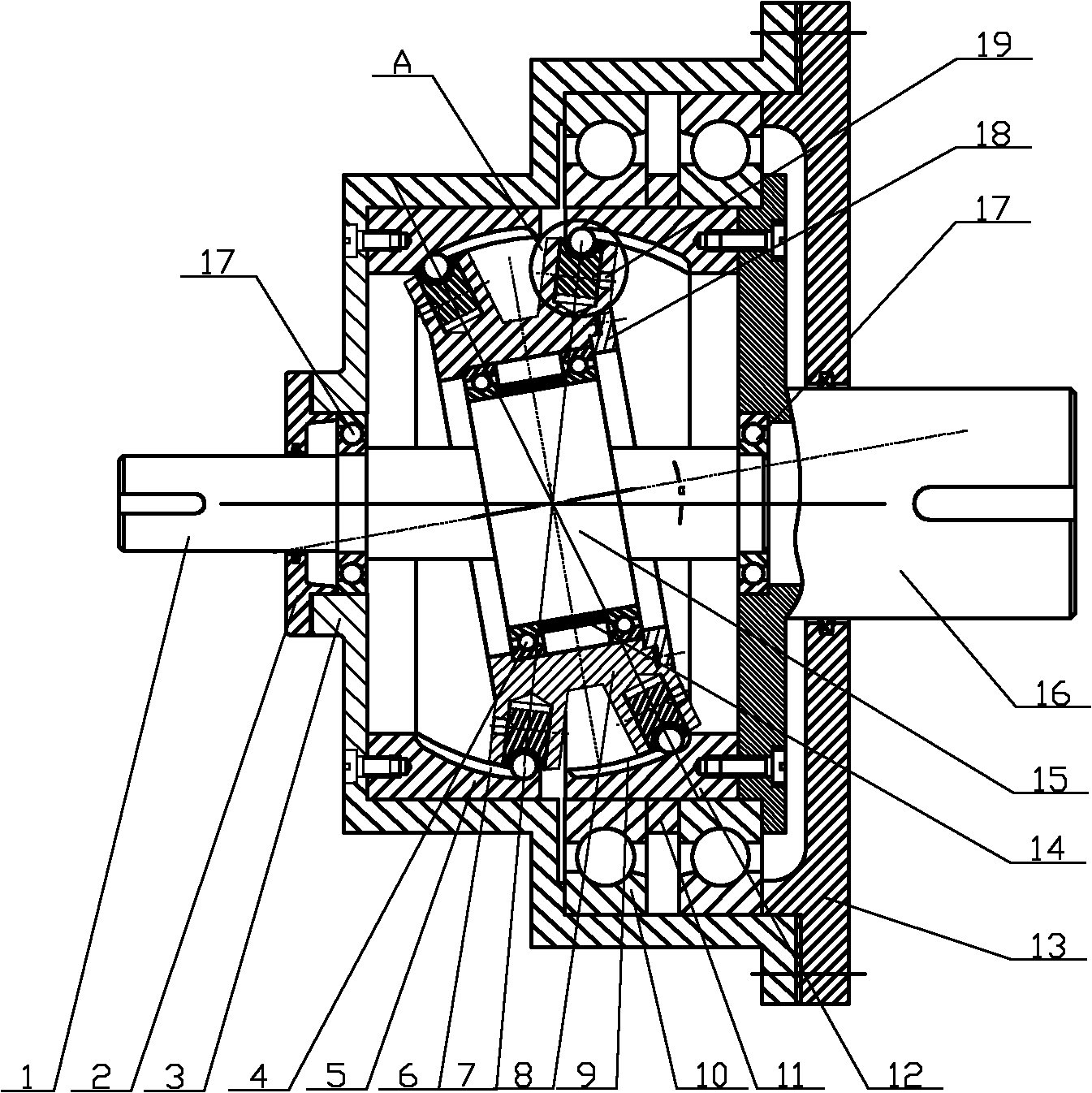

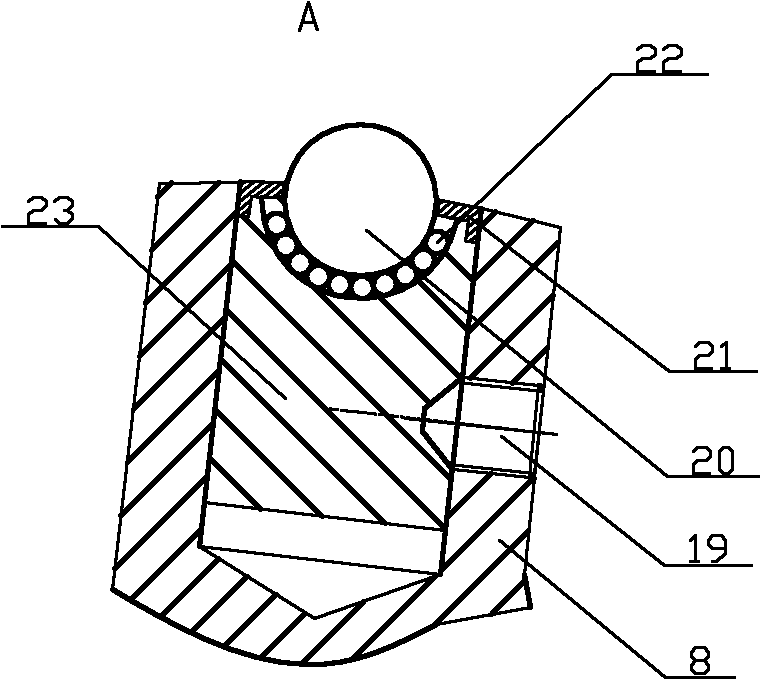

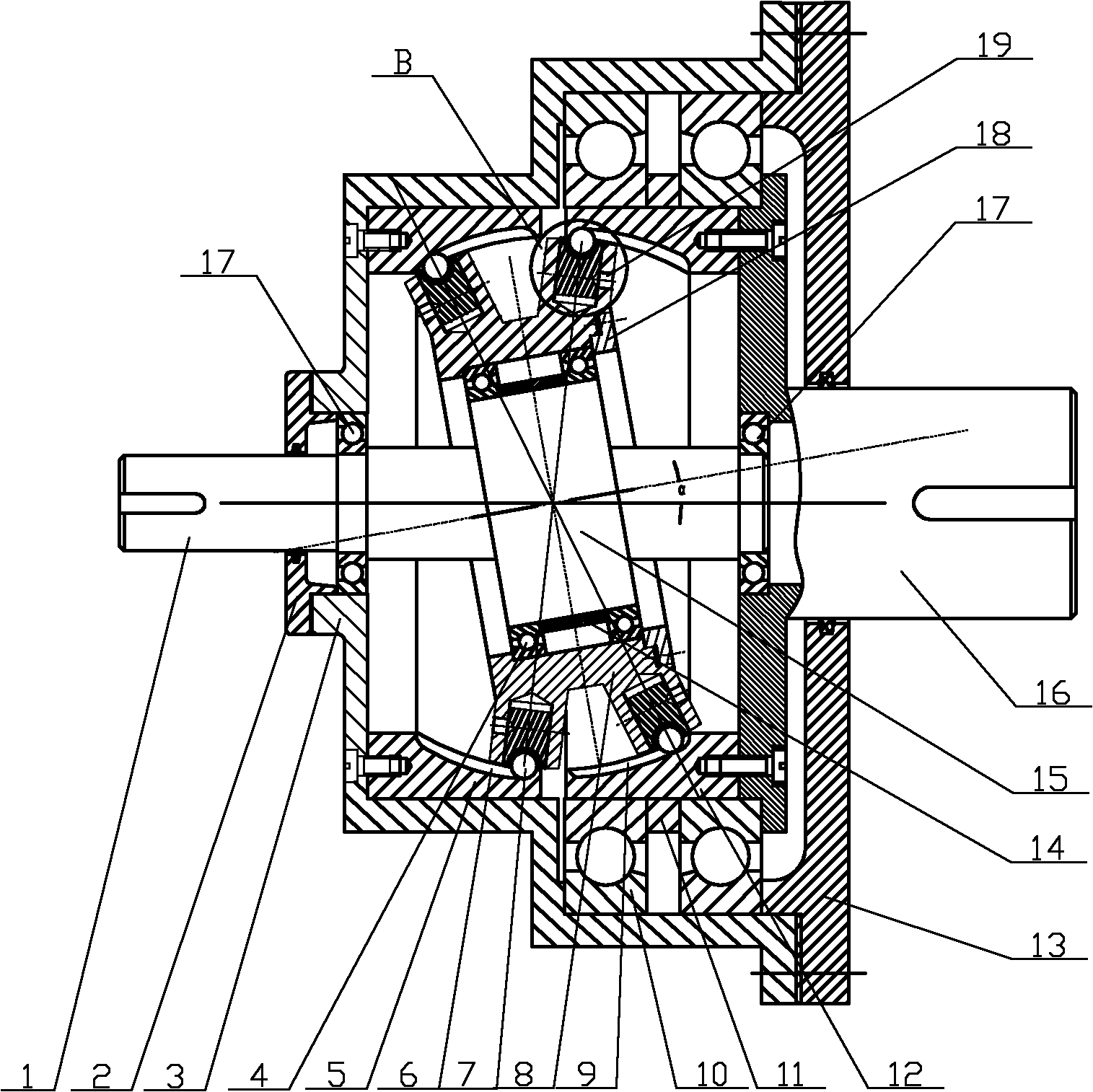

[0024] figure 1 , 2Shown is one of the embodiments of the present invention, it is two bulls-eye type ball rolling pairs 7 in the fixed disk tooth groove 6 and the rotating disk tooth groove 9 adopting closed meshing transmission nutating movable tooth reduction device; Its structure includes machine base 3, input shaft 1, support bearing 17, fixed disk 5, rotating disk 12, rotating disk bearing 10, nutating disk movable tooth transmission mechanism, output shaft end cover 13 and output shaft 16; Support bearing end cover 2, support bearing 17, fixed disc 5, rotating disc 12, output shaft 16 and output shaft end cover 13 connected with rotating disc 12 are installed in the shaft hole of input end in sequence; 3 Two rotating disk bearings 10 are installed on the rotating disk 12 between the inner walls, and a rotating disk sleeve 11 is arranged on the rotating disk between the two rotating disk bearings 10, and one end of the input shaft 1 is connected to the On the motor sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com