Fatigue testing machine

A technology of fatigue testing machine and motor cover, applied in the field of fatigue testing machine, can solve the problems of increased processing time, waste of processing materials, simple processing method, etc., and achieve the effects of unlimited stroke length, material saving and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

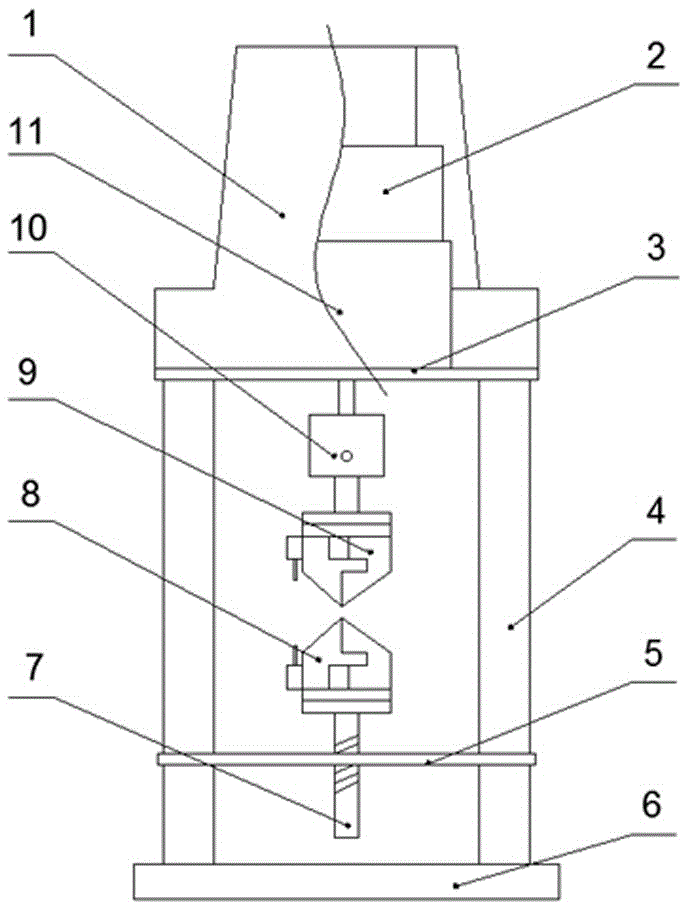

[0014] exist figure 1 Among them, the mechanical part of the fatigue testing machine is composed of a motor cover, a voice coil motor, a fixture, an upper support plate, a motor support plate, a middle plate, a column, a bottom plate, etc.; the voice coil motor is fixed on the motor support, and the motor is equipped with Motor cover; the two columns stand vertically on the bottom plate, and the middle plate and the upper support plate are installed on the columns; the upper clamp is connected with the upper support plate through the connecting piece; the lower clamp is installed on the The middle plate; the frame part includes two support columns, the middle plate, an adjusting rod with threads and an upper support plate supporting the voice coil linear motor. The threaded adjusting rod passes through the middle plate, and when the adjusting rod is manually operated, the two clamps can freely move up and down. In this way, the adjustment range of the two clamps can be determ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com