Short tube flexible gear harmonic reducer of rigid wheel tooth dip angle and transmission rigidity testing device thereof

A harmonic reducer and flex wheel technology, applied in the field of short-tube flex wheel harmonic reducer and its transmission stiffness testing device, can solve the problem of reduced transmission stiffness, complicated operation process, between the teeth of the rigid wheel and the teeth of the flex wheel. Reduce the contact area and other problems to achieve the effect of improving the transmission rigidity, increasing the contact area, and improving the meshing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

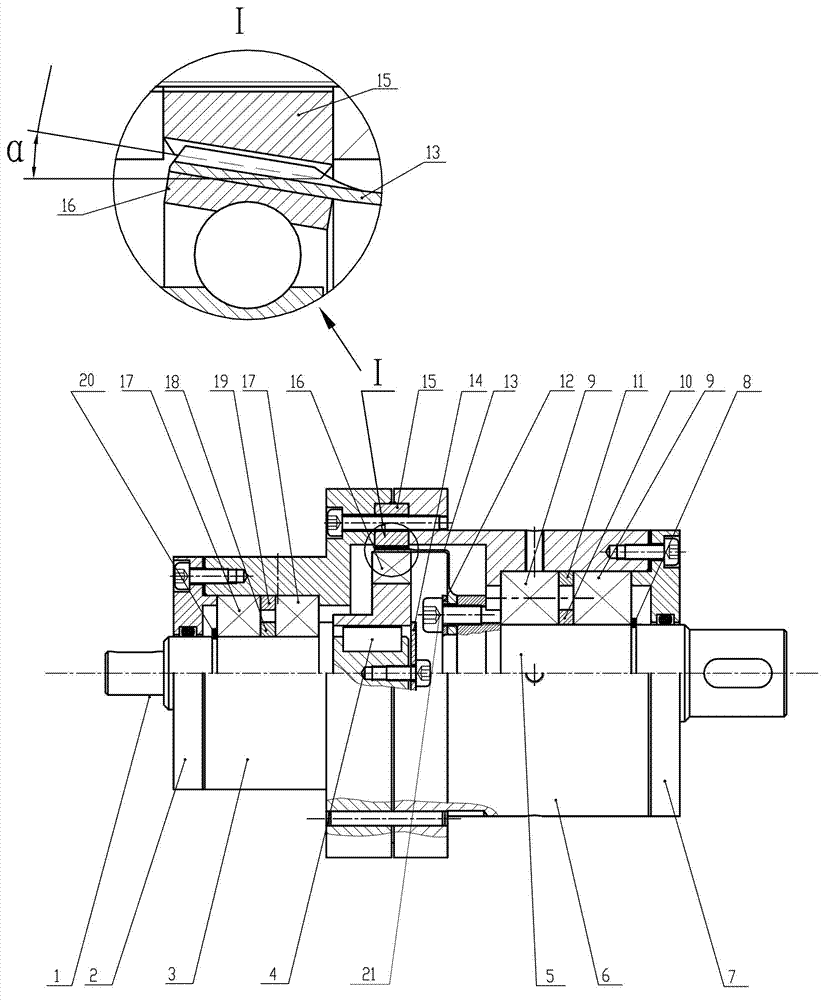

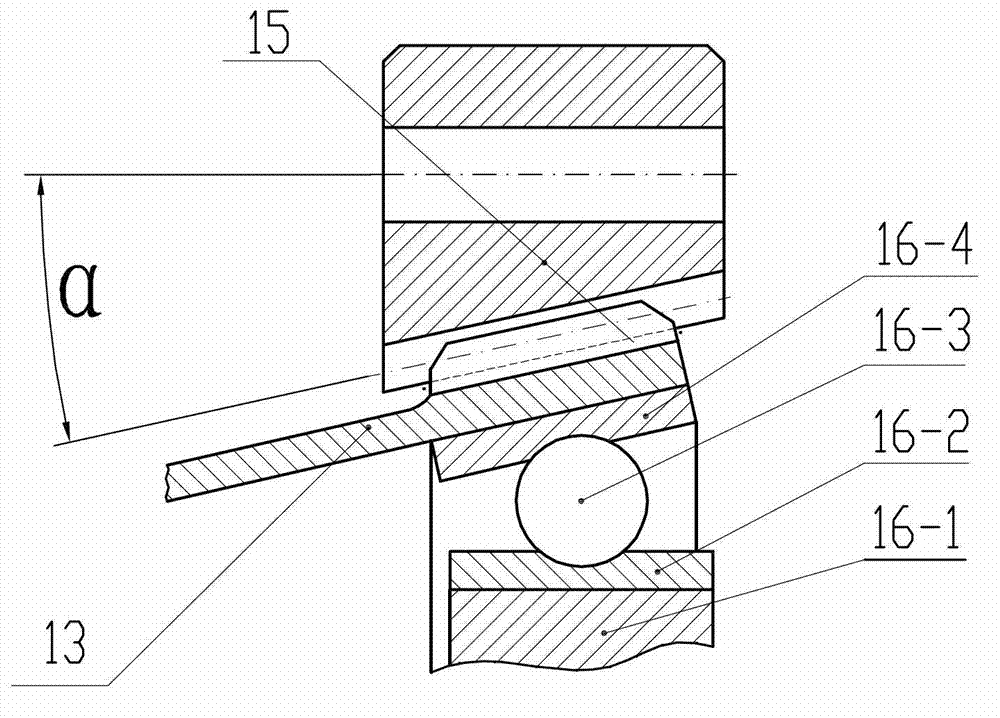

[0016] Specific implementation mode one: as Figure 1~2 As shown, the short tube flex spline harmonic reducer with inclination angle of the rigid wheel teeth described in this embodiment includes a rigid spline 15 with inclination teeth, a flex spline 13 and a wave generator 16, and the wave generator 16 is installed on the flex spline. Inside the wheel 13, the rigid spline 15 with inclination teeth is set on the flex spline 13, and the internal teeth on the rigid spline 15 with inclination angle mesh with the external teeth on the flex spline 13; the flex spline 13 has an aspect ratio of 1 / 4 to 3 / 5 of the flexible spline, the rigid spline 15 with the inclination angle of the tooth is the tooth with an inclination angle α along the axis of the rigid spline, and the inclination direction of the inclination angle α is the same as that of the flexspline at the long axis. The direction of opening angle is the same, and the inclination angle α is 0.1°~1°.

specific Embodiment approach 2

[0017] Specific implementation mode two: as Figure 1~2 As shown, the harmonic reducer in this embodiment also includes an input shaft 1, an output shaft 5, an input end cover 2, an input end housing 3, an output end cover 7, an output end housing 6, two input shafts Angular contact bearing 17, input shaft bearing inner ring gasket 18, input shaft bearing outer ring gasket 19, two output shaft angular contact bearings 9, output shaft bearing inner ring gasket 10, output shaft bearing outer ring gasket 11, The baffle plate 14 and the pressure plate 12, the input shaft spring retainer 20 and the output end spring retainer 8; the rigid wheel 15 with the inclination of the gear teeth is fixed on the input end housing 3 and the output end housing 6, and the input shaft 1 and the wave generation The device 16 is connected by the key 4, and the flexible spline 13 is fastened on the output shaft 5 by the screw 21 and the pressure plate 12; two input shaft angular contact ball bearings...

specific Embodiment approach 3

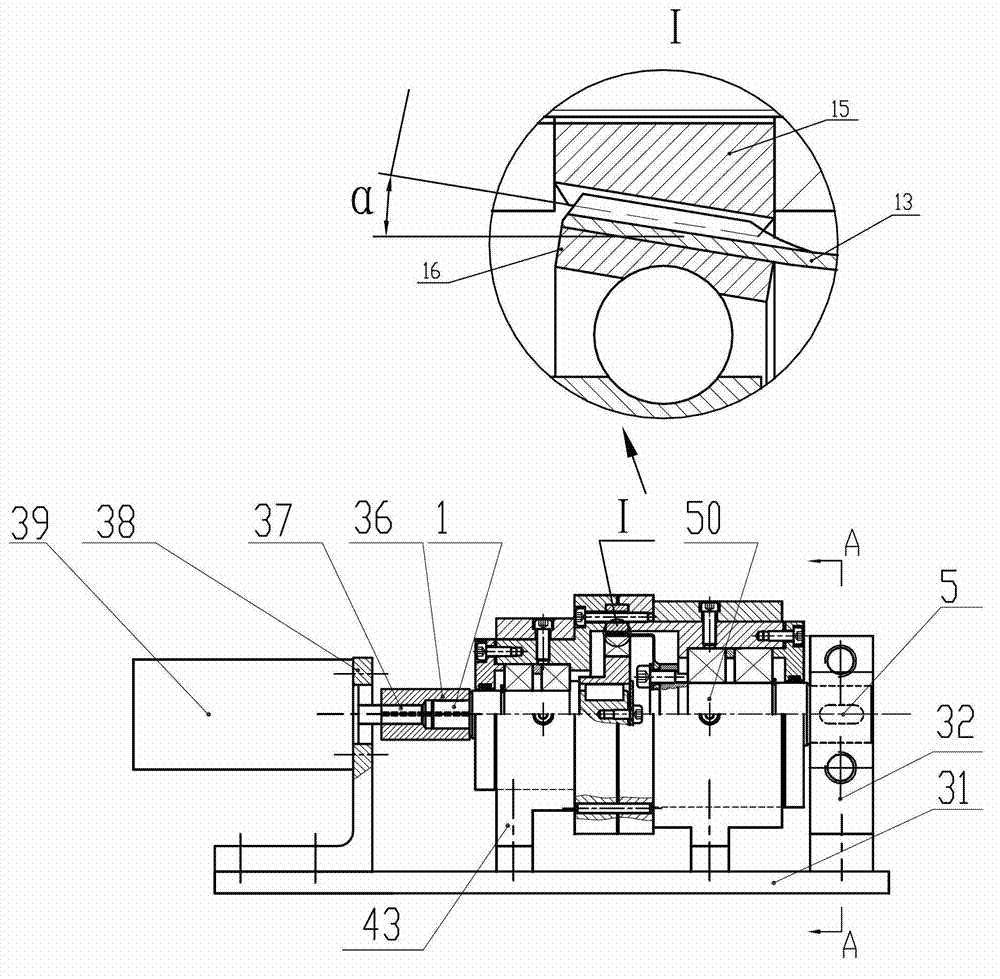

[0019] Specific implementation mode three: as Figure 1~4As shown, this embodiment is the transmission stiffness testing device of the short-tube flexible wheel harmonic reducer described in the second specific embodiment. The transmission stiffness testing device includes a base plate 31, a motor support base 38, a servo motor 39, a rigid coupling Device 36, harmonic reducer support seat 43, left lock clamping end 32 and right clamping lock end 41, motor support base 38 is fixed on the base plate 31, servo motor 39 is fixed on the motor support base 38, servo motor The motor shaft 37 of 39 is fixedly connected with the input shaft 1 through the rigid coupling 36, the harmonic reducer is fixed on the harmonic reducer support base 43, and the harmonic reducer support base 43 is fixed on the base plate 3-1 , the output shaft 5 of the harmonic reducer is clamped and locked by the left clamping end 32 and the right clamping end 41 through the lower clamping screw 40 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com