Coal-charging transmission gear for tamping coke oven

A technology for transmission devices and tamping coke ovens, applied in charging devices, coke ovens, petroleum industry, etc., can solve the problems of poor transmission rigidity, long transmission links, and poor stability of coal cakes, etc., so as to reduce the weight of the mechanism, The effect of increasing transmission stiffness and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

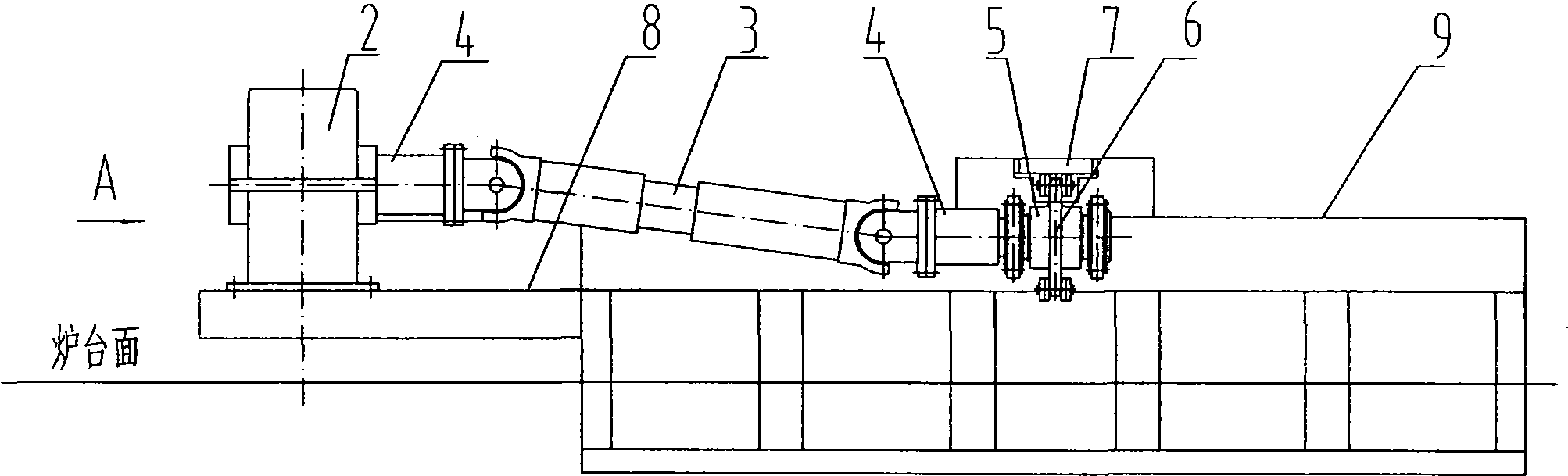

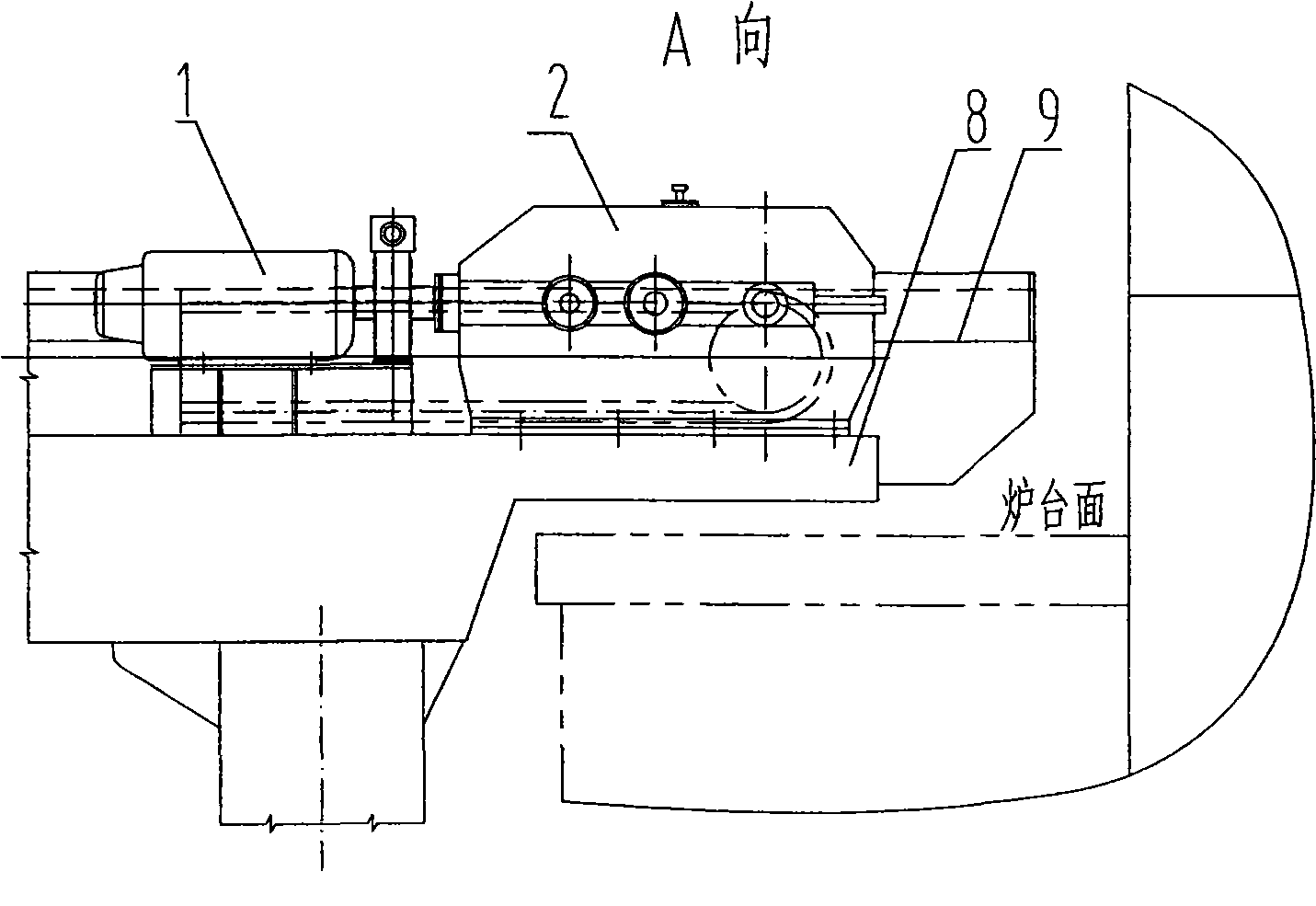

[0011] Such as figure 1 , 2 As shown, in order to solve the problem of the height difference between the reducer installation platform and the car body platform on the coke oven coal charging site, so that the reducer and the sprocket shaft cannot be directly connected, the present invention combines the installation platform 8 of the reducer with the car body platform 9 The heights are staggered, and the height of the reducer installation platform 8 is appropriately reduced, so that the reducer 2, the sprocket shaft 5 and the universal joint 3 are directly connected, and the inclination angle required for the use of the universal joint is satisfied.

[0012] A coal charging transmission device for tamping coke ovens, the motor 1 is connected with the universal coupling 3 through the reducer 2 through the connecting flange 4, and the other end of the universal coupling 3 is connected through the connecting flange 4 Linked with sprocket shaft 5. Sprocket shaft 5 drives sprock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com