Three-gear parallel shaft type double-motor three-planet-row hybrid power system

A parallel shaft, planetary row technology, applied in the field of power system, can solve the problems of low maximum speed of the motor, large axial length of the assembly, poor adaptability of the vehicle model, etc., and reduce the size of the motor, reduce the axial size, and reduce the cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

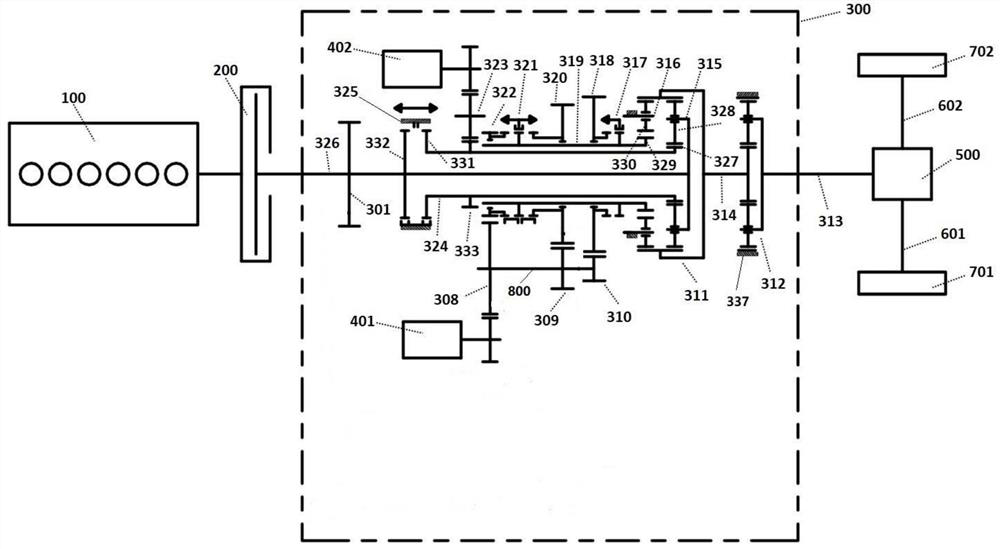

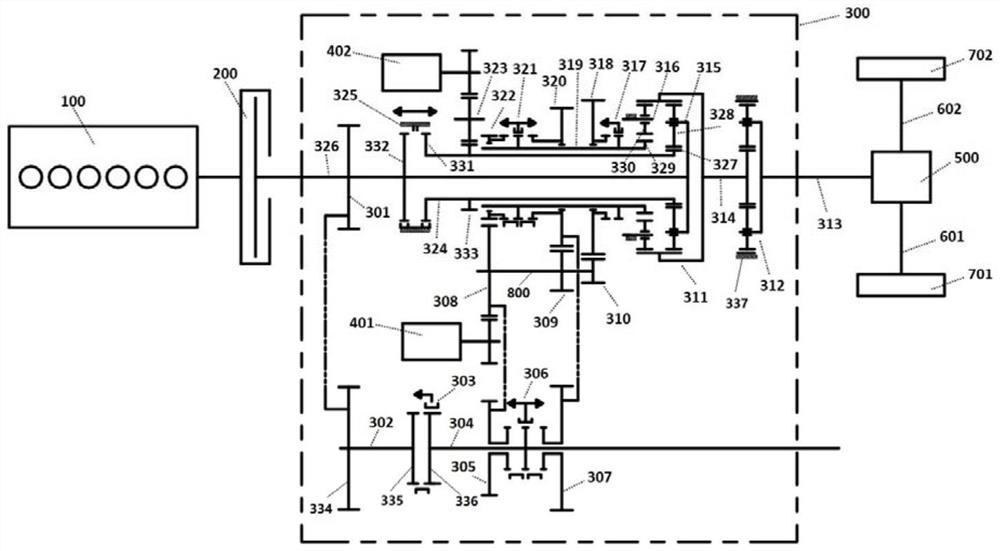

[0042] Such asfigure 1 , figure 2 As shown, it is an embodiment of the present invention, which provides a three-speed parallel-shaft dual-motor three-planetary hybrid power system, including an engine 100, a flexible connector 200, a housing 300, a central shaft 326, and a first hollow shaft 324 , the second hollow shaft 319, the output front shaft 314, the output rear shaft 313, the first planetary row, the second planetary row, and the third planetary row;

[0043] The central shaft 326, the first hollow shaft 324, the second hollow shaft 319, the output front shaft 314, the first planetary row, the second planetary row, the third planetary row, the first motor 402, and the second motor 401 are all arranged on Inside the casing 300;

[0044] The first hollow shaft 324 is sleeved on the central shaft 326, and the second hollow shaft 319 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com