Rock wool fiberizing centrifuge

A cotton fiber-forming centrifuge, centrifugal roller technology, applied in glass manufacturing equipment, manufacturing tools and other directions, can solve the problems of inconvenient installation, high production and maintenance costs, achieve convenient connection and disassembly, ensure stability and service life, Improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

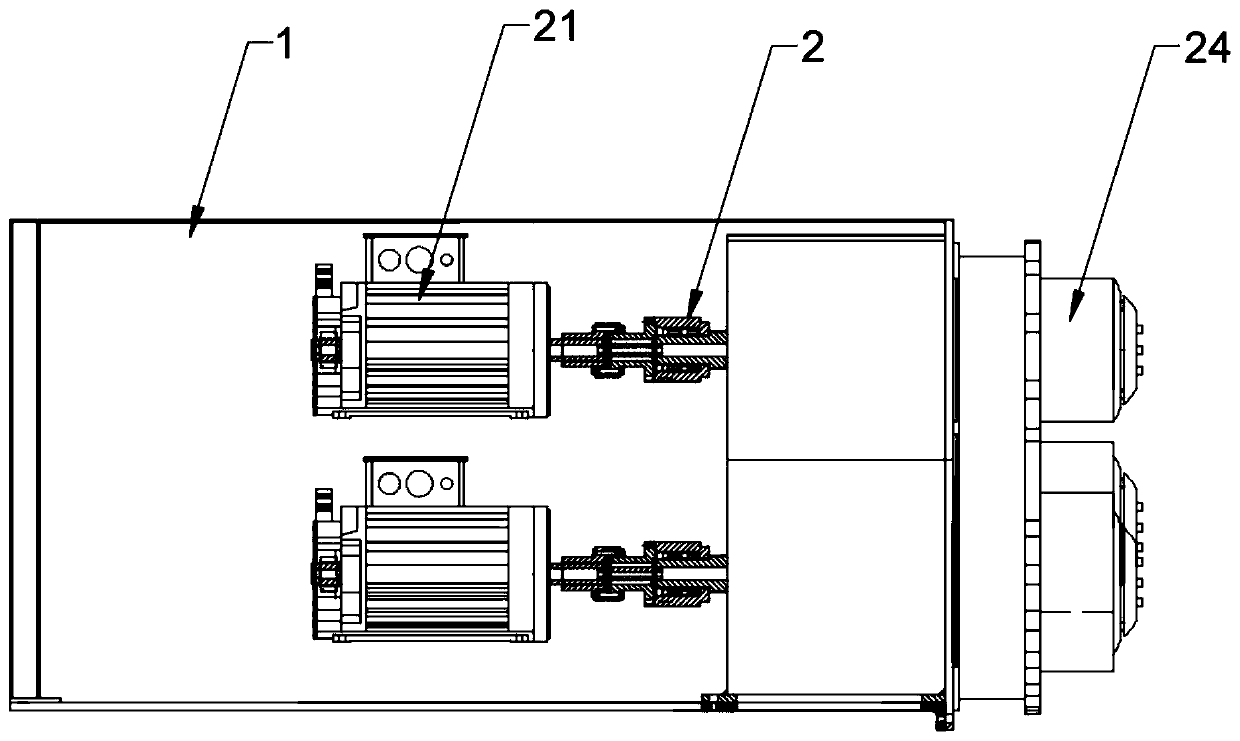

[0043] See figure 1 , the rock wool fiber-forming centrifuge of this embodiment includes a frame 1, a plurality of centrifugal roller assemblies 2 arranged on the frame 1, a split glue spray ring 3 arranged around the centrifugal roller assembly 2 provided, and a centrifugal Roller assembly 2 and the glue supply mechanism for the split glue spray ring.

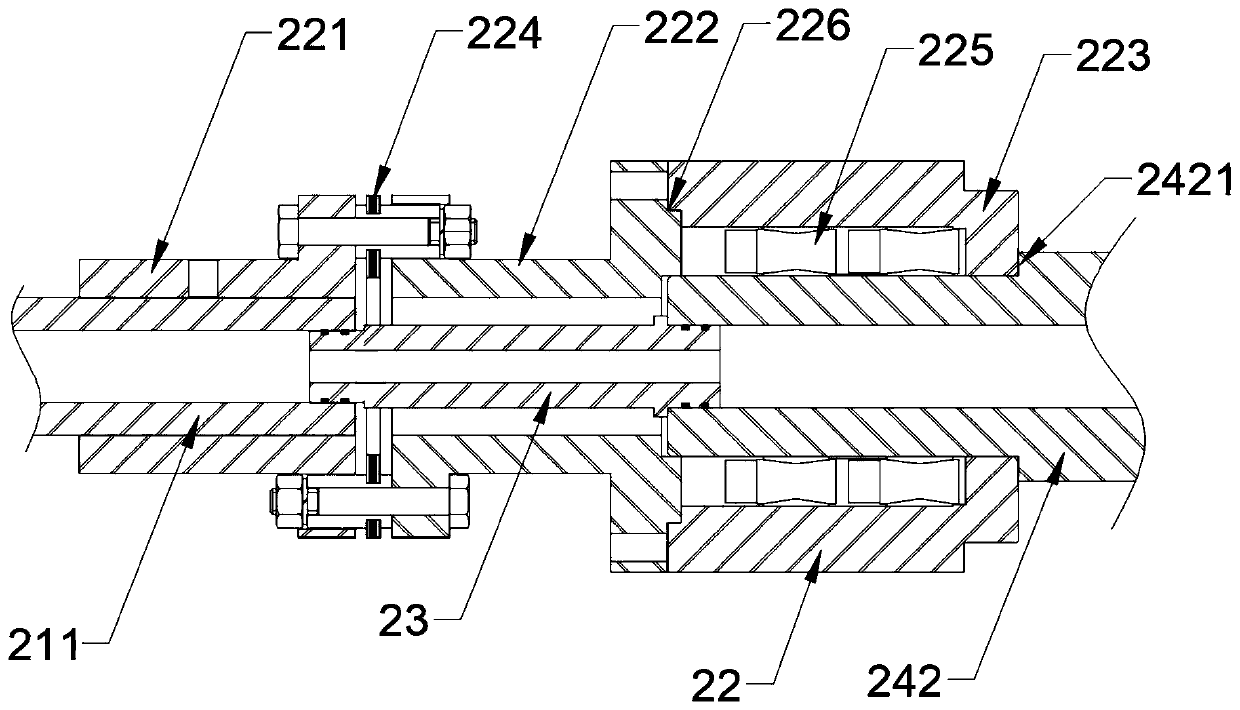

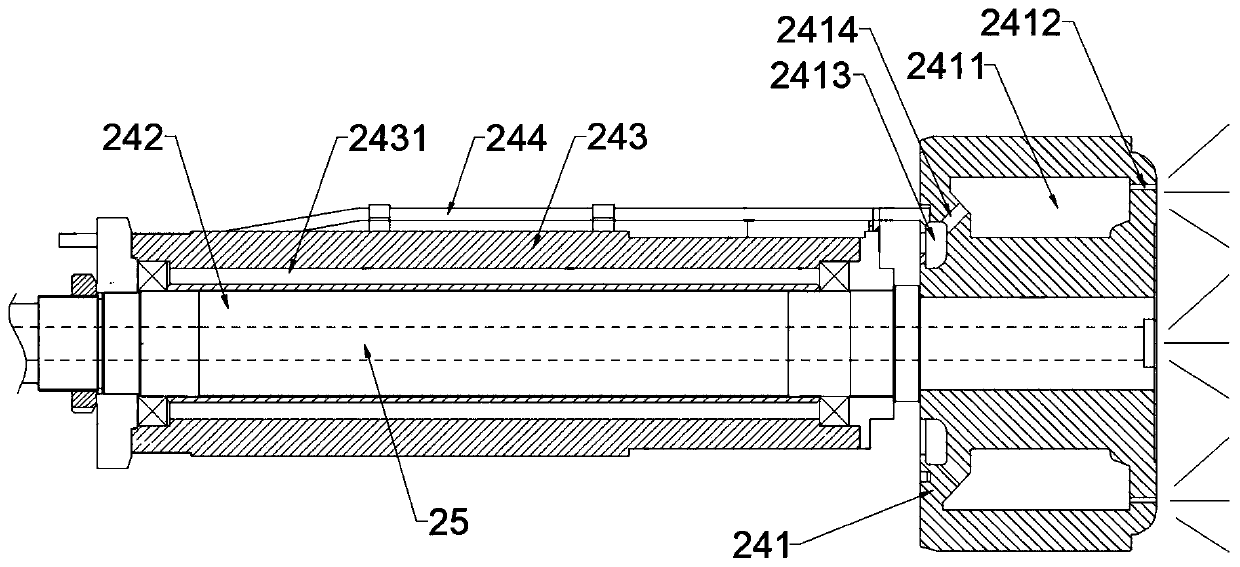

[0044] See figure 2 and image 3, The centrifugal roller assembly 2 includes a motor 21 , a coupling 22 , a connecting pipe 23 and a roller body 24 . The output shaft 211 of the motor 21 is a hollow shaft passing through the two ends of the motor 21, so glue can be fed from the output shaft 211 of the motor 21. The output shaft 211 of the motor 21 is fixedly connected with the roller body 24 through a coupling 22 .

[0045] The shaft coupling 22 includes a first shaft sleeve 221 , a second shaft sleeve 222 and a third shaft sleeve 223 fixedly connected by bolts in sequence. The first sleeve 221 and the third sleeve 223 a...

Embodiment 2

[0058] See Image 6 , this embodiment is basically the same as Embodiment 2, except that: the first sleeve 221 and the third sleeve 223 of the shaft coupling 22 of the centrifugal roller assembly 2 are respectively sleeved on the output shaft 211 of the motor 21 and the roller body 24; the sides of the first shaft sleeve 221 and the third shaft sleeve 223 are fixedly connected with the output shaft 211 of the motor 21 and the roller body 24 respectively by screws; between the first shaft sleeve 221 and the second shaft sleeve 222, and the Diaphragms 224 are disposed between the second bushing 222 and the third bushing 223 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com