Vertical lifting device for cassette

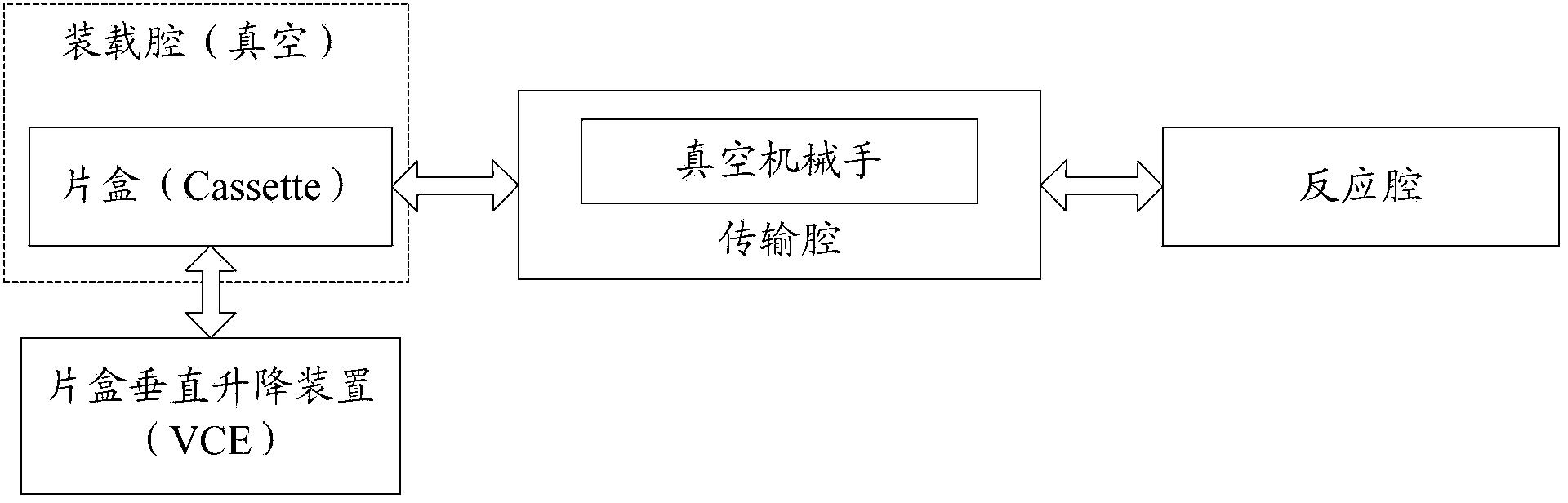

A technology of vertical lifting and film box, which is applied in the direction of lifting device, lifting frame, transportation and packaging, etc. It can solve the requirements of high neutrality of elastic connectors, high requirements of assembly accuracy of parts, and inconvenient structural disassembly, assembly and maintenance, etc. problems, to achieve the effect of reducing the number of transmission chain stages, reducing assembly and maintenance work, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

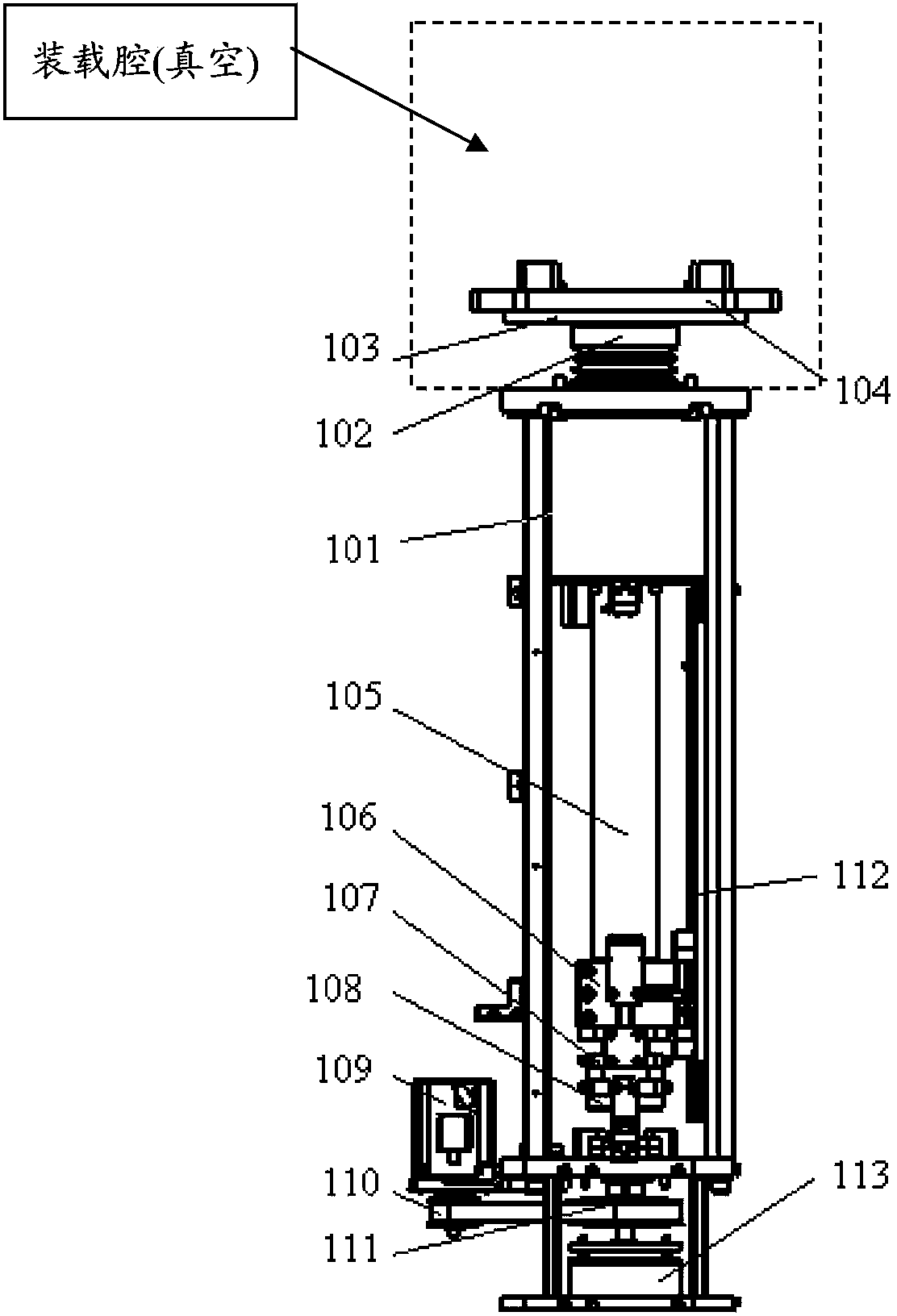

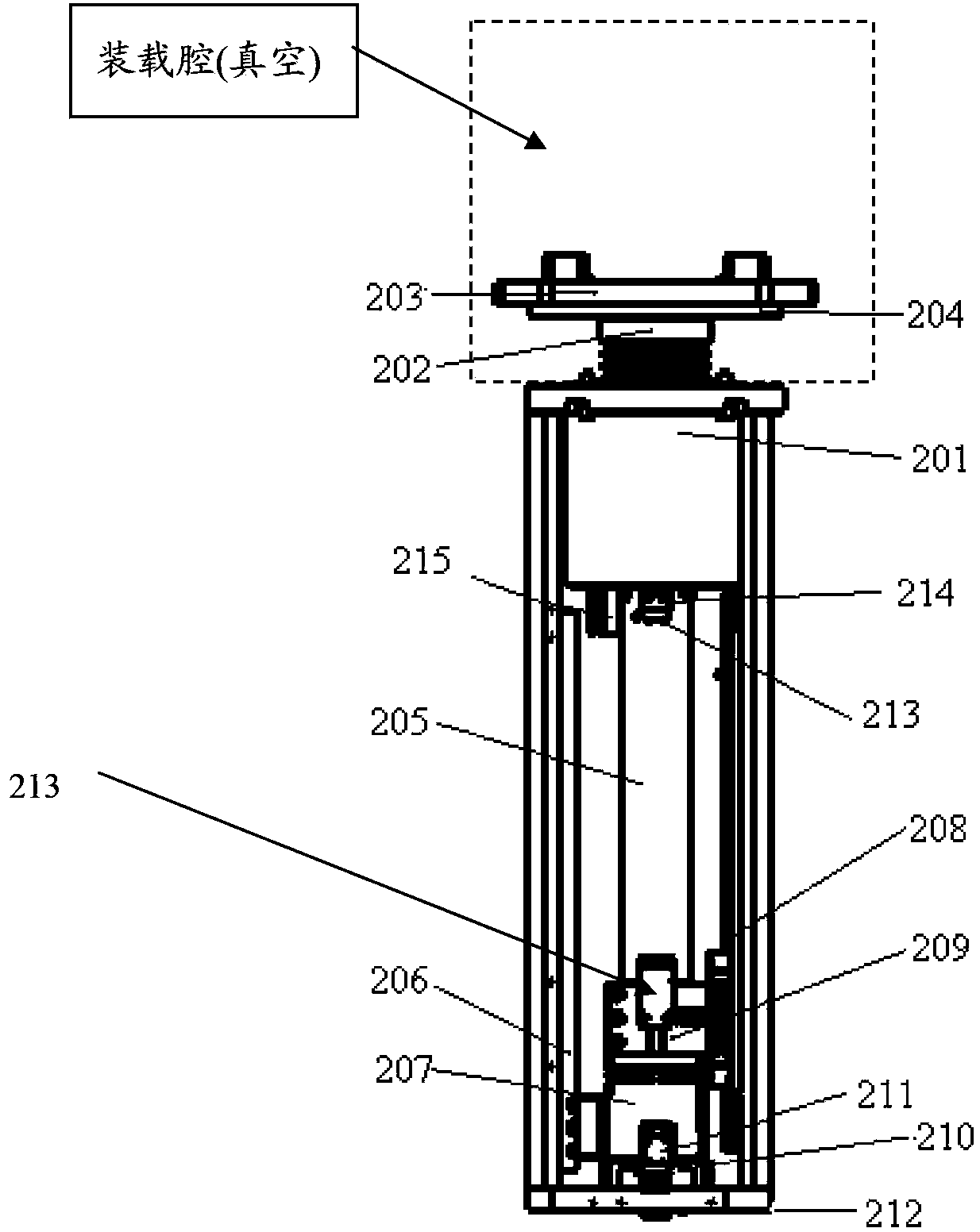

[0039] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0040] Aiming at the problems of complex structure, cumbersome installation, inconvenient disassembly and maintenance, high installation precision and low positioning accuracy of the vertical lifting device in the background technology, the embodiment of the present invention provides a new vertical lifting device. One of its core ideas is to drive the film cassette up and down by a linear motor, which reduces the number of transmission chain stages and basically realizes "zero-stage transmission"; uses a simple flexible structure instead of elastic connectors that need to be assembled from multiple parts, thereby simplifying the The structure of the cassette vertical lifting device is improved, which is convenient for installation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com