Hybrid power driving system

A drive system, hybrid technology, applied in hybrid vehicles, power plants, pneumatic power plants, etc., can solve the problems of reduced energy efficiency, large energy loss, low transmission efficiency, etc., to shorten the axial distance, improve Energy efficiency, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

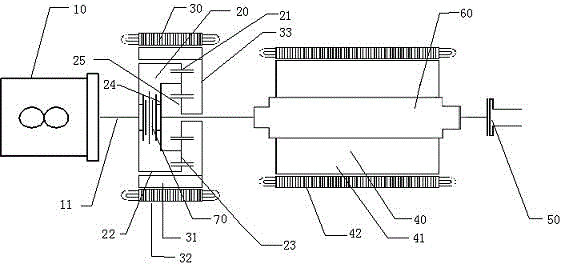

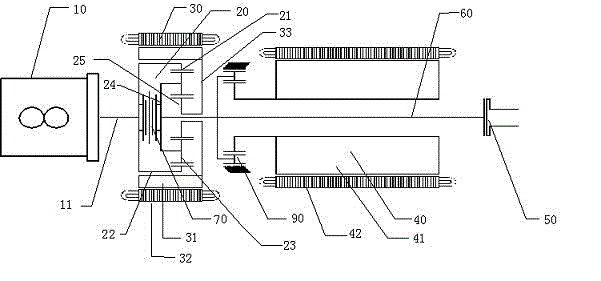

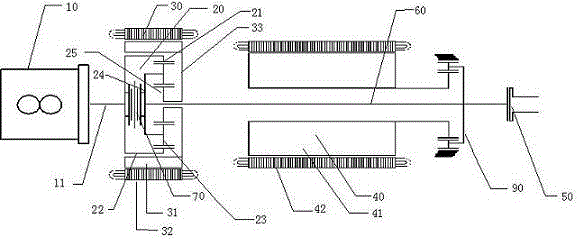

[0030] figure 1 Shown is a hybrid drive system described in this embodiment, including

[0031] an engine 10 having an output shaft 11;

[0032] A planetary gear mechanism 20, which includes a ring gear 21, a plurality of planetary gears fixed coaxially with the output shaft 11 at the center of the ring gear 21, a plurality of planetary gears internally meshed with the ring gear 21, and planetary gears fixed with the planetary gear 23 The carrier 24 and the sun gear 25 externally meshed with the planetary gear 23;

[0033] The generator 30 has a generator rotor 31 and a generator stator 32, and the generator rotor is coaxially fixed with the sun gear 25. In this embodiment, the generator rotor 31 is provided with a fixing device 33. The fixing device 33 is fixed coaxially with the sun gear 25, and the fixing device may be a fixing bracket;

[0034] The motor 40 has a motor rotor 41 and a motor stator 42, the motor rotor 41 is connected with the planet carrier 24 through an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com