Ring structured travelling wave type contactless liquid medium ultrasonic wave electric machine

An ultrasonic motor, traveling wave type technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the difficulty of high-precision control system design, drive rotor rotation Weakness and high stator resonance frequency, the speed identification strategy is simple, the system cost is reduced, and the motor life is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

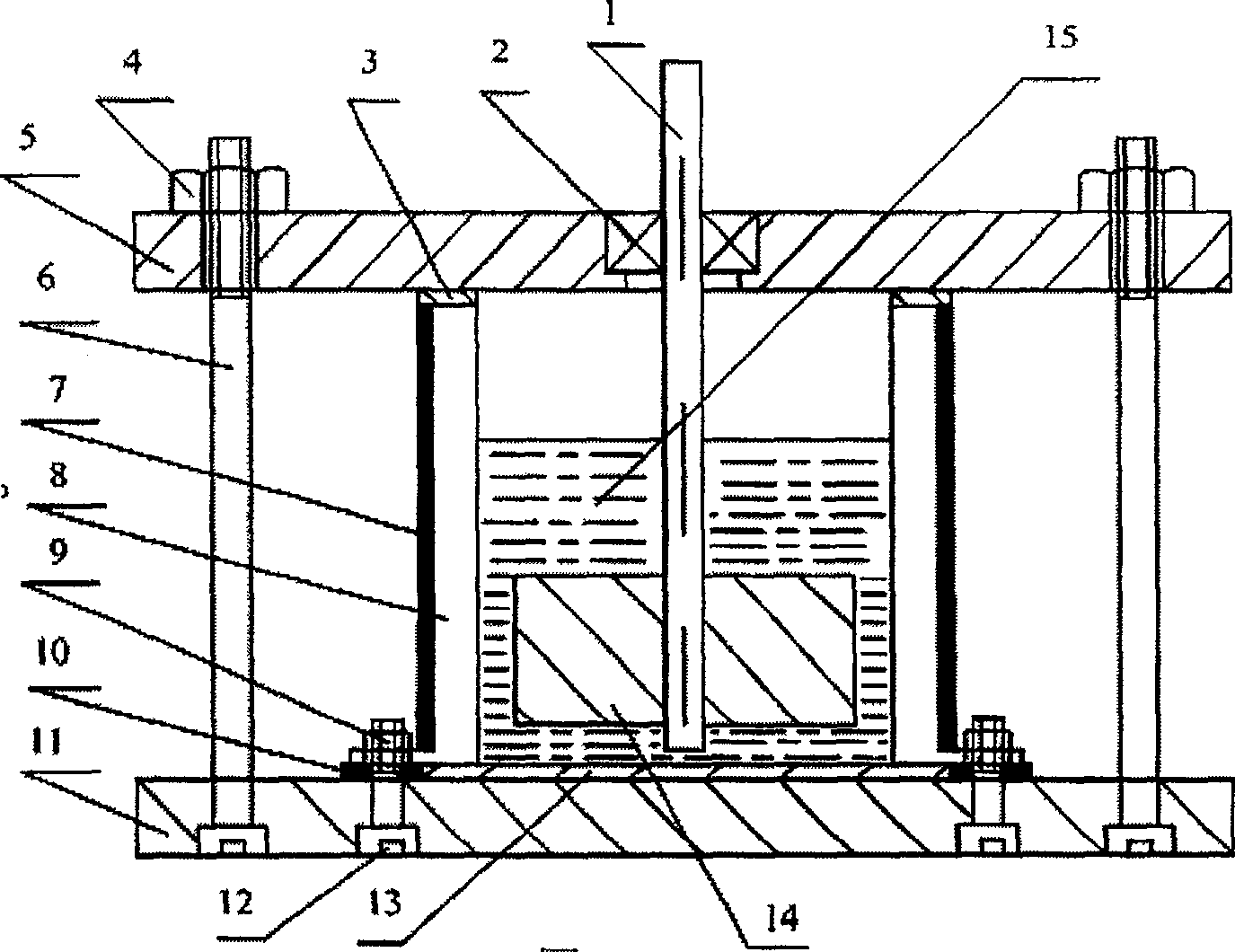

[0023] The invention is a novel ultrasonic motor which uses the strong sound field generated by the vibration of the stator to excite the sound flow in the liquid, and drives the rotor to rotate through the sound flow. It is mainly composed of stator, rotor, liquid medium and bracket. like figure 1 As shown, the stator body 7 is circular, and the piezoelectric ceramic sheet 3 is pasted on the outside, and the lower surface is sealed with a rubber substrate 12. The boss at the bottom of the stator and the base 10 are fixed by a screw 11 and a nut 8. Between the boss and the base 10 Set gasket 9 between. The stator ring is filled with liquid 14 at a certain height, and the rotor 13 with blades is immersed in the liquid without direct contact with the stator. The rotating shaft 1 is installed on the cover plate 5 through the bearing 2 . The cover plate 5 and the base 11 of the bracket assembly are fixedly connected together by the screw rod 6 and the nut 4 .

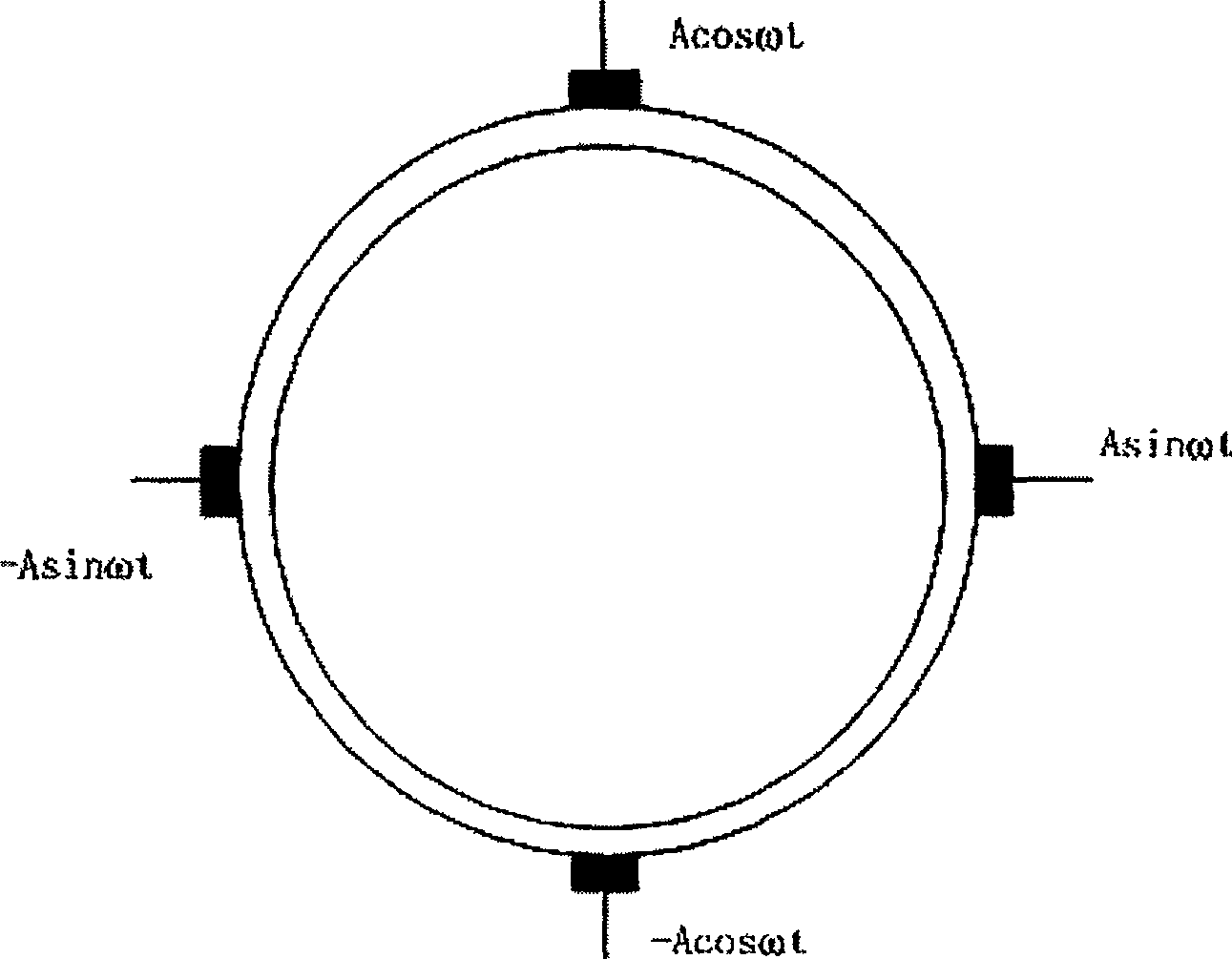

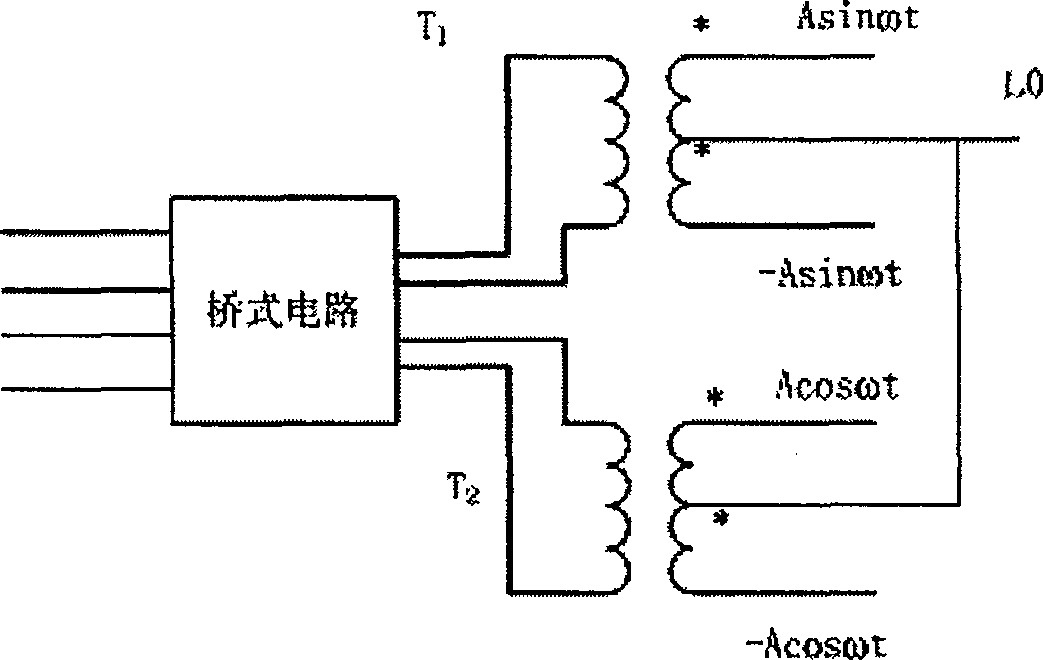

[0024] figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com