Preparation method of submicron transition metal boride powder with low oxygen content

A transition metal, sub-micron-level technology, applied in the direction of metal borides, boron/borides, etc., can solve the problems of many impurities, low activity, coarse powder particle size, etc., and achieve strong controllability, low agglomeration degree, and oxygen content low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First weigh 100mmol of ZrO 2 and 400mmol of elemental boron, with ethanol as solvent, Si 3 N 4 The balls were used as ball milling media, mixed on a roller mill for 24 hours, and dried by rotary evaporation to obtain ZrO 2 / B mixed powder; then ZrO 2 / B mixed powder is placed in a graphite crucible, heated to 1000°C in a graphite furnace at an air pressure lower than 200Pa and kept for 2 hours to obtain ZrB 2 / B 2 o 3 Powder.

[0027] The above ZrB 2 / B 2 o 3 Put the powder in a beaker, add deionized water, heat and stir, the water temperature is controlled at 80°C, stir for 6 hours, and centrifuge for 20 minutes to obtain ZrB 2 Powder.

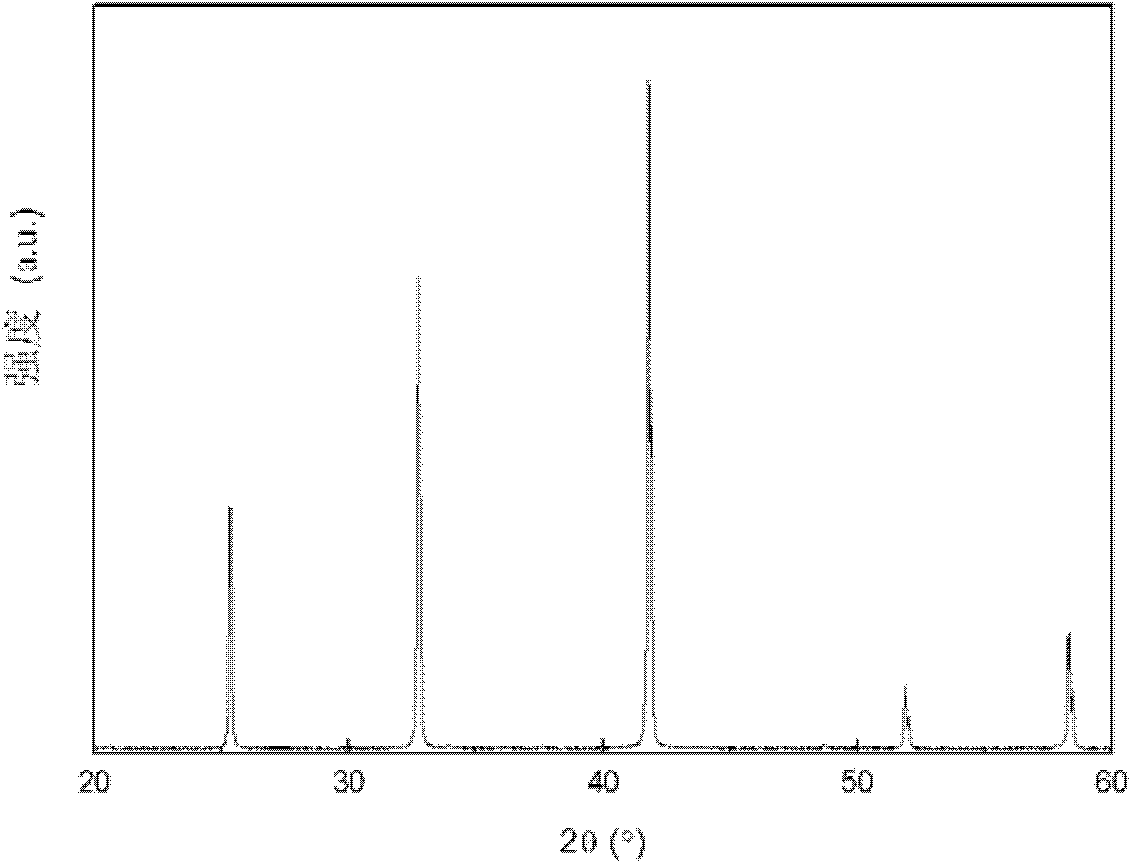

[0028] ZrB will be obtained 2 The powder is placed in a graphite crucible, heated to 1500°C in a graphite furnace with an air pressure lower than 200Pa and kept at a temperature of 3 hours to obtain the submicron ZrB with low oxygen content 2 Powder.

[0029] Oxygen content was measured with an oxygen and nitrogen analyzer...

Embodiment 2

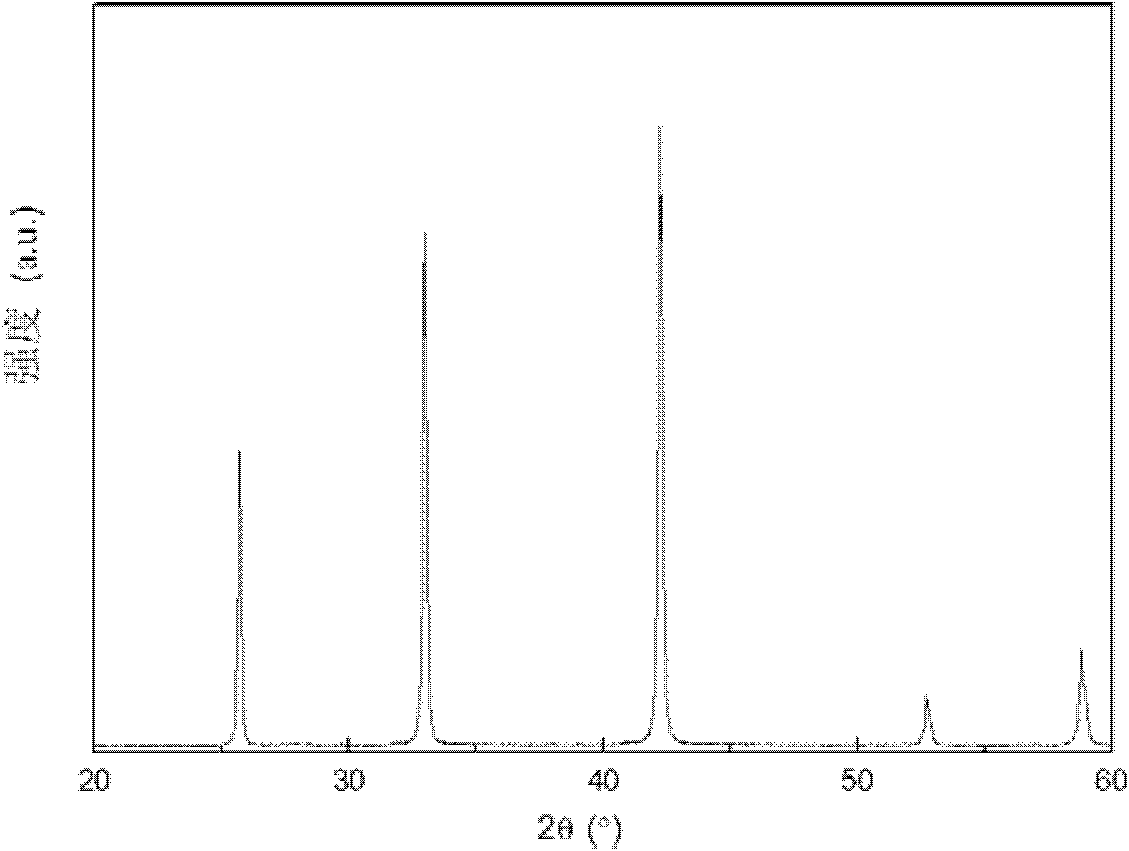

[0033] First weigh 100mmol of HfO 2 and 400mmol of elemental boron, with ethanol as solvent, Si 3 N 4 The balls are used as the ball milling medium, mixed on a roller ball mill for 24 hours, and dried by rotary evaporation to obtain HfO 2 / B mixed powder; then HfO 2 / B mixed powder is placed in a graphite crucible, heated to 1000°C in a graphite furnace at an air pressure lower than 200Pa and kept for 2 hours to obtain HfB 2 / B 2 o 3 Powder.

[0034] The above HfB 2 / B 2 o 3 Put the powder in a beaker, add deionized water, heat and stir, the water temperature is controlled at 80°C, stir for 6 hours, and centrifuge for 20 minutes to obtain HfB 2 Powder.

[0035] HfB will be obtained 2The powder is placed in a graphite crucible, heated to 1500°C in a graphite furnace with an air pressure lower than 200Pa and kept for 3 hours to obtain the low-oxygen content submicron HfB 2 Powder.

[0036] The measured oxygen content was 0.2 wt%.

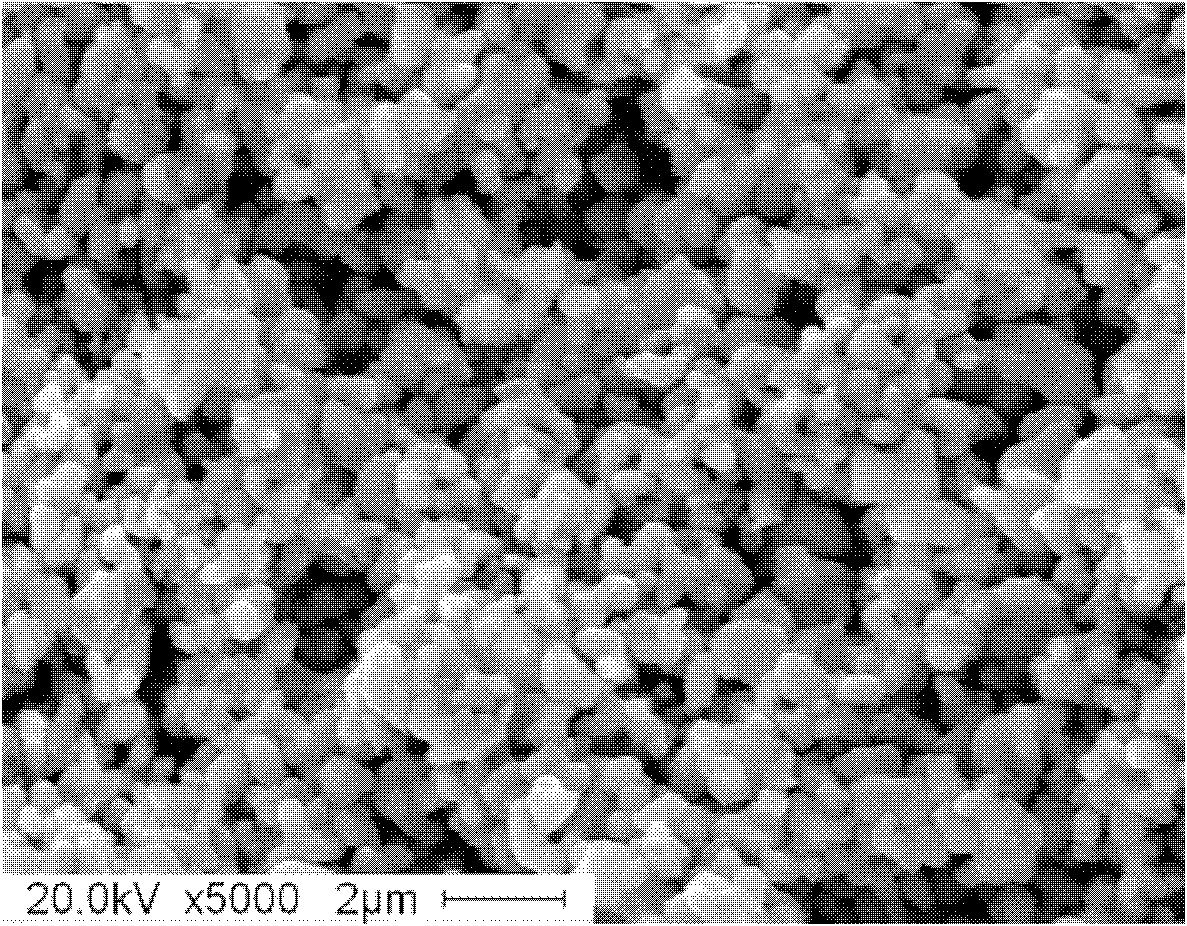

[0037] image 3 The HfB prepared...

Embodiment 3

[0040] The difference between this example and Example 1 is that "400 mmol of elemental boron" is replaced with "300 mmol of elemental boron", and the rest of the content is the same as that of Example 1.

[0041] Know through detecting and analyzing: the ZrB that present embodiment makes 2 The average particle diameter of the powder is 400nm, and the oxygen content is 0.5wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com