Electrochemical energy device and manufacturing method thereof

An electrochemical and energy technology, applied in the field of capacitors, can solve the problems of not optimistic application prospects, no increase in capacitance, low decomposition voltage, etc., and achieve superior electrochemical performance and alkali resistance stability, promote migration, and short reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044]Dissolve 1g of CS powder in 50ml of 2% acetic acid solution, stir until a transparent and uniform solution; add PDDA aqueous solution according to the mass ratio of CS to PDDA = 1:0.5, and continue stirring to prepare a uniform solution of PDDA, and cast the mixed solution into plastic In a disc, dry naturally to form a film. The film was peeled off and placed in an oven. After physical cross-linking at 120°C for 1 hour, it was soaked in 4% glutaraldehyde-acetone solution and stirred for 1 hour. After that, the film was taken out and fully washed by soaking in deionized water.

[0045] The membrane prepared by the above method was immersed in 2M KOH solution for ion exchange for 24 hours and then taken out, and the KOH adsorbed on the surface of the membrane was repeatedly washed with deionized water to neutrality to obtain a basic anion exchange composite membrane.

Embodiment 2

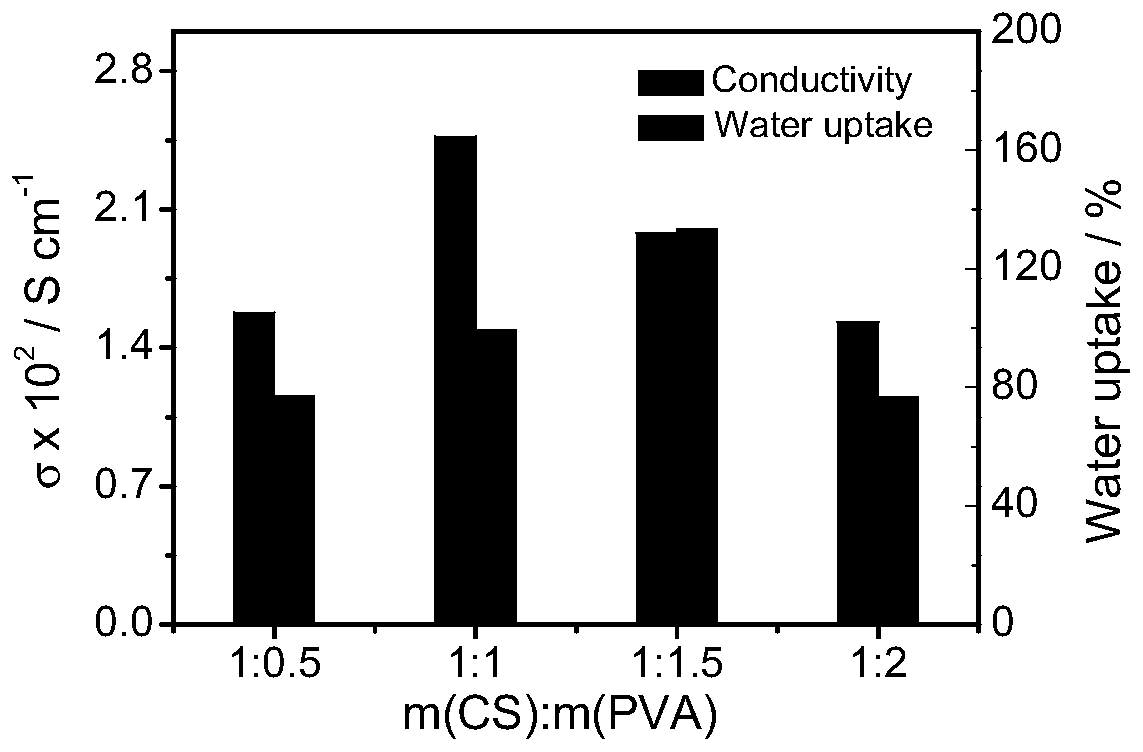

[0047] Dissolve 1g of CS powder in 50ml of 2% acetic acid solution, stir until a transparent and homogeneous solution; add PDDA aqueous solution according to the mass ratio of CS to PDDA = 1:0.5, and continue stirring to prepare a homogeneous solution of PDDA; the mass ratio of CS to PDDA is 1:0.5 PVA aqueous solution was added to the PDDA uniform solution, stirred for 24 hours to obtain a uniform mixed solution, the mixed solution was cast into a plastic disc, and naturally dried to form a film. The film was peeled off and placed in an oven. After physical cross-linking at 120°C for 1 hour, it was soaked in 4% glutaraldehyde-acetone solution and stirred for 1 hour. After that, the film was taken out and fully washed by soaking in deionized water.

[0048] The membrane prepared by the above method was immersed in 2M KOH solution for ion exchange for 24 hours and then taken out, and the KOH adsorbed on the surface of the membrane was repeatedly washed with deionized water to neu...

Embodiment 3

[0050] Dissolve 1g of CS powder in 50ml of 2% acetic acid solution, stir until a transparent and homogeneous solution; add PDDA aqueous solution according to the mass ratio of CS to PDDA = 1:0.5, and continue stirring to prepare a homogeneous solution of PDDA; the mass ratio of CS to PDDA is 1:1 PVA aqueous solution was added to PDDA uniform solution, stirred for 24 hours to obtain a uniform mixed solution, the mixed solution was cast into a plastic disc, and naturally dried to form a film. The film was peeled off and placed in an oven. After physical cross-linking at 120°C for 1 hour, it was soaked in 4% glutaraldehyde-acetone solution and stirred for 1 hour. After that, the film was taken out and fully washed by soaking in deionized water.

[0051] The membrane prepared by the above method was immersed in 2M KOH solution for ion exchange for 24 hours and then taken out, and the KOH adsorbed on the surface of the membrane was repeatedly washed with deionized water to neutralit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com