High-nickel ternary positive electrode material as well as preparation method and application thereof

A positive electrode material, high-nickel technology, applied in the field of high-nickel ternary positive electrode materials and its preparation, can solve problems such as large internal stress, achieve the effects of reducing stress, good cycle stability, and suppressing microcracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

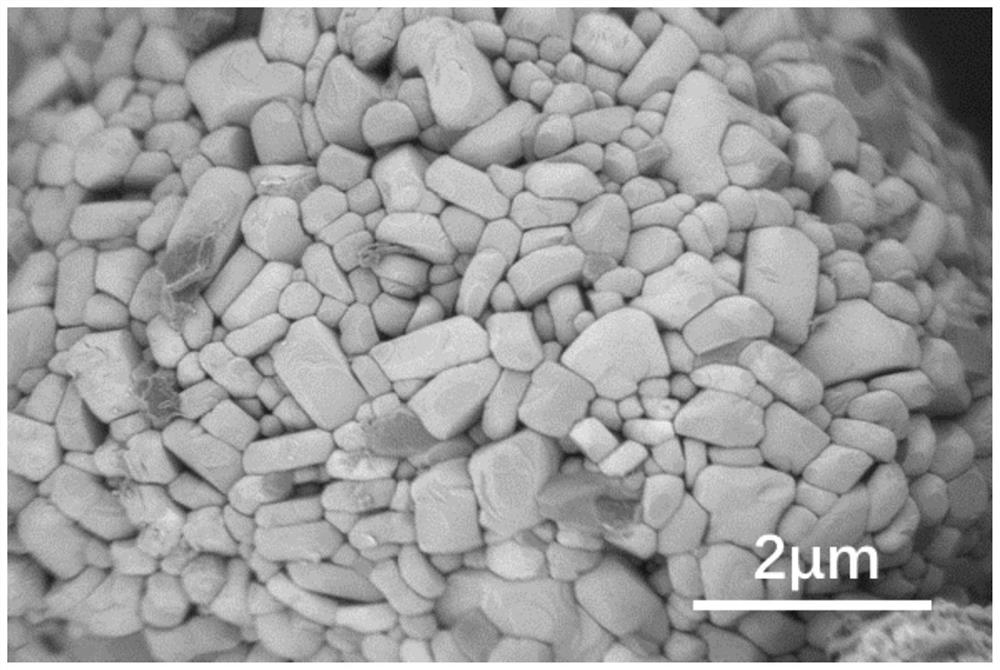

[0036] A method for preparing a high-nickel ternary positive electrode material, comprising the following steps:

[0037] (1) Preparation of precursor nickel cobalt manganese hydroxide (Ni0.96 co 0.01 mn 0.03 (OH) 2 ): 6056g of NiSO 4 ·6H 2 O, 67 g of CoSO 4 ·7H 2 O and 122g of MnSO 4 ·H 2 O was dissolved in 12L of deionized water, and the obtained metal sulfate aqueous solution was continuously injected into the batch reactor. At the same time, 14.4L of NH with a concentration of 2mol / L 3 ·H 2 O solution and 12 L of NaOH solution with a concentration of 4 mol / L were injected into the reactor, and the precursor was filtered after the precursor grew to about 10 μm, then washed, and finally vacuum-dried at 110 °C for 12 hours to obtain the precursor Ni 0.96 co 0.01 mn 0.03 (OH) 2 ;

[0038] (2) Take 500g Ni 0.96 co 0.01 mn 0.03 (OH) 2 The precursor was mixed with 230g of lithium hydroxide and 16.96g of diboron trioxide by dry ball milling. The ball milling time ...

Embodiment 2

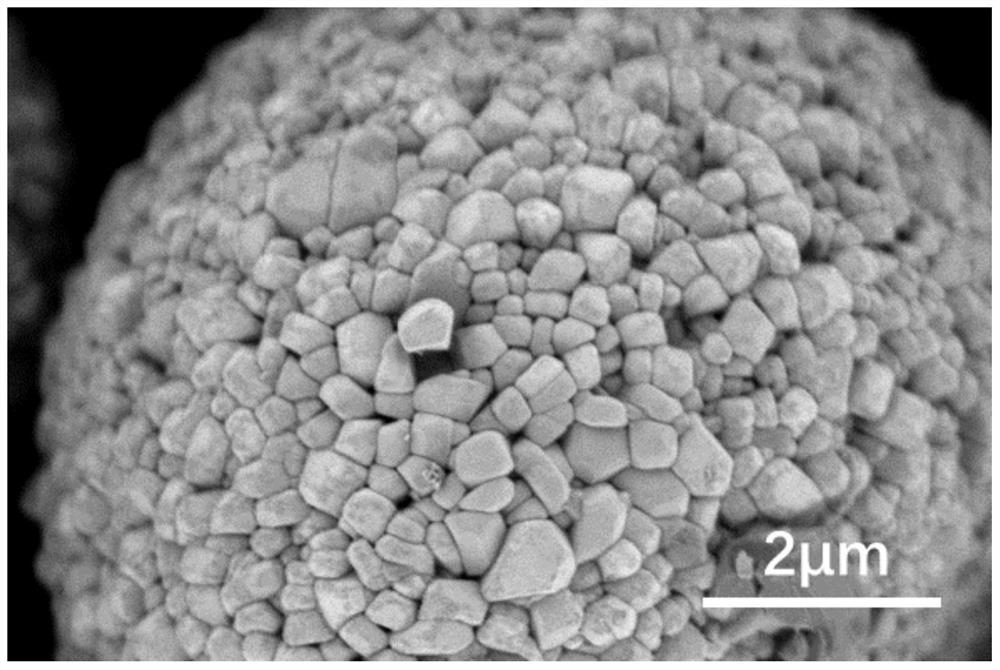

[0040] A method for preparing a high-nickel ternary positive electrode material, comprising the following steps:

[0041] (1) Preparation of precursor nickel cobalt manganese hydroxide (Ni 0.96 co 0.01 mn 0.03 (OH) 2 ): the preparation method is as described in step (1) of Example 1;

[0042] (2) Take 500g Ni 0.96 co 0.01 mn 0.03 (OH) 2 The precursor was mixed with 230g lithium hydroxide and 30.12g boric acid by dry ball milling, and the ball milling time was 5h. After mixing evenly, calcinate at 800°C for 20 hours in an oxygen atmosphere, cool naturally to room temperature after the calcination, and pass through a 300-mesh sieve to remove oversized particles, and then obtain a boron-doped high-nickel ternary cathode material LiNi 0.95 co 0.01 mn 0.03 B 0.01 o 2 .

Embodiment 3

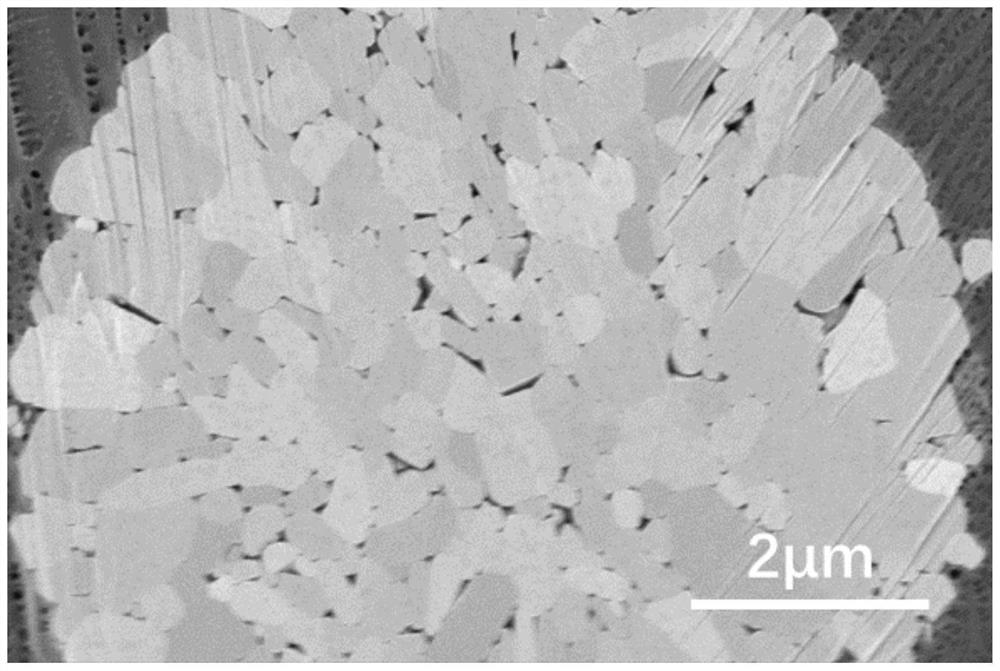

[0044] A method for preparing a high-nickel ternary positive electrode material, comprising the following steps:

[0045] (1) Preparation of precursor nickel cobalt manganese hydroxide (Ni 0.96 co 0.01 mn 0.03 (OH) 2 ): the preparation method is as described in step (1) of Example 1;

[0046] (2) Take 500g Ni 0.96 co 0.01 mn 0.03 (OH) 2 The precursor was mixed with 230g of lithium hydroxide and 19.49g of ammonium pentaborate by dry ball milling, and the ball milling time was 5h. After mixing evenly, calcinate at 800°C for 20 hours in an oxygen atmosphere, cool naturally to room temperature after the calcination, and pass through a 300-mesh sieve to remove oversized particles, and then obtain a boron-doped high-nickel ternary cathode material LiNi 0.95 co 0.01 mn 0.03 B 0.01 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com