Preparation method of boron oxide-modified microporous molecular sieve shape-selective catalyst

The technology of microporous molecular sieve and catalyst is applied in the field of preparation of boron oxide modified microporous molecular sieve shape-selective catalyst, can solve the problems of complicated preparation operation and high cost of shape-selective catalyst, and achieves improved shape-selective performance, low cost, and shape-selective effect. high performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

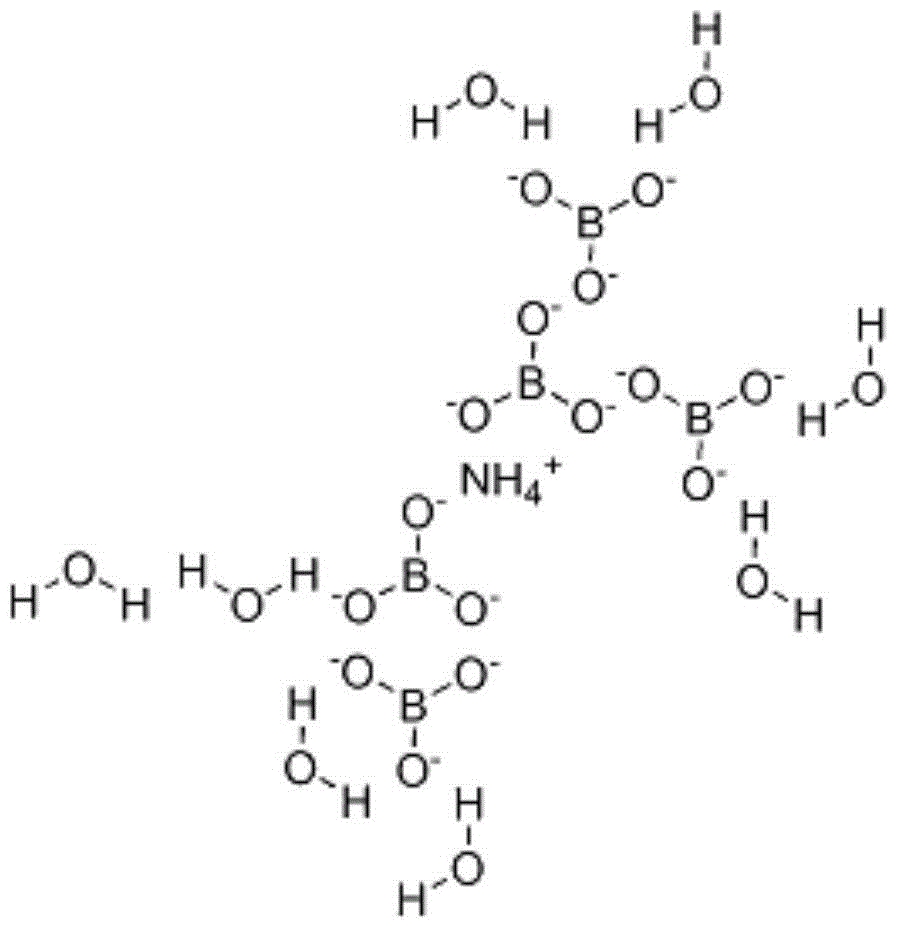

Image

Examples

Embodiment 1

[0017] Add ammonium pentaborate to deionized water, wherein the mass ratio of ammonium pentaborate to deionized water is 1:5, stir until completely dissolved; then add microporous molecular sieve ZSM-5 to the above solution, in which ammonium pentaborate and microporous The mass ratio of molecular sieve ZSM-5 was 1:2, stirred evenly, and stood at room temperature for 12 hours; the obtained material was evaporated to dryness in a water bath, then put into a 120°C oven to dry for 6 hours, and then transferred to a muffle furnace, in the air In the atmosphere, the temperature was raised to 550°C at a rate of 10°C / min, and kept at this temperature for 4 hours, and then lowered to room temperature to obtain a boron oxide-modified microporous molecular sieve shape-selective catalyst, denoted as Cat1.

Embodiment 2

[0019] Add ammonium pentaborate to deionized water, wherein the mass ratio of ammonium pentaborate to deionized water is 1:10, stir until completely dissolved; then add microporous molecular sieve ZSM-5 to the above solution, in which ammonium pentaborate and microporous The mass ratio of molecular sieve ZSM-5 was 1:2, stirred evenly, and stood at room temperature for 12 hours; the obtained material was evaporated to dryness in a water bath, then put into a 120°C oven to dry for 6 hours, and then transferred to a muffle furnace, in the air In the atmosphere, the temperature was raised to 550°C at a rate of 10°C / min, and kept at this temperature for 4 hours, and then lowered to room temperature to obtain a boria-modified microporous molecular sieve shape-selective catalyst, denoted as Cat2.

Embodiment 3

[0021] Add ammonium pentaborate to deionized water, wherein the mass ratio of ammonium pentaborate to deionized water is 1:5, stir until completely dissolved; then add microporous molecular sieve ZSM-5 to the above solution, in which ammonium pentaborate and microporous The mass ratio of molecular sieve ZSM-5 was 1:8, stirred evenly, and stood at room temperature for 12 hours; the obtained material was evaporated to dryness in a water bath, then put into a 120°C oven to dry for 6 hours, and then transferred to a muffle furnace. In the atmosphere, the temperature was raised to 550°C at a rate of 10°C / min, and kept at this temperature for 4 hours, and then lowered to room temperature to obtain a boron oxide-modified microporous molecular sieve shape-selective catalyst, denoted as Cat3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com