Boron fertilizer effervescence granule and method of producing the same

A boron fertilizer and effervescent technology, which is applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of complicated processes, increased use costs for farmers, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

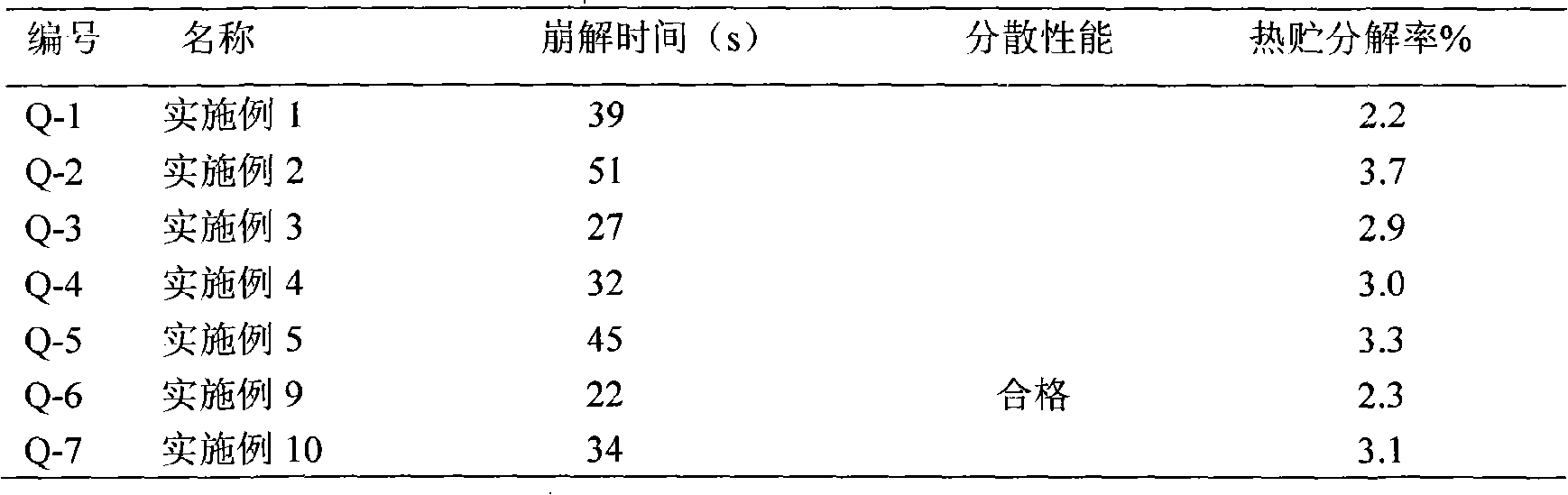

Examples

Embodiment 1

[0073] Weigh the raw materials of each component according to the following ratio

[0074] Boric acid 80 parts

[0075] Potassium bicarbonate 10 parts

[0076] Succinic acid half ester sulfonate fatty acid amide 5 parts

[0077] Sodium dodecylbenzenesulfonate 5 parts

[0078] The above components are mixed evenly, and the mother powder is prepared by pulverizing, and the mother powder is uniformly mixed with an appropriate amount of alcohol solution, then extruded and granulated, dried, analyzed and tested, and put into storage to obtain boric acid effervescent granules.

Embodiment 2

[0080] Weigh the raw materials of each component according to the following ratio

[0081] Sodium tetraborate decahydrate 61 parts

[0082] 3 parts caproic acid

[0083] Calcium carbonate 5.4 parts

[0084] Starch 30.6 parts

[0085] The above components are mixed, pulverized to prepare mother powder, mixed evenly with an appropriate amount of alcohol solution, then extruded and granulated, dried, analyzed and checked for storage to obtain sodium tetraborate decahydrate (borax) effervescent granules.

Embodiment 3

[0087] Weigh the raw materials of each component according to the following ratio

[0088] Sodium tetraborate pentahydrate 70 parts

[0089] Sodium bicarbonate 8 parts

[0090] Tartaric acid 13 parts

[0091] Alkylphenol polyoxyethylene ether succinate sulfonate 9 parts

[0092] The above components are mixed, pulverized to prepare mother powder, mixed evenly with an appropriate amount of alcohol solution, then extruded and granulated, dried, analyzed and tested, and put into storage to obtain sodium tetraborate pentahydrate effervescent granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tube height | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com