Electrolyte of aluminum electrolytic capacitor, preparation method thereof and aluminum electrolytic capacitor

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of short service life and poor high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

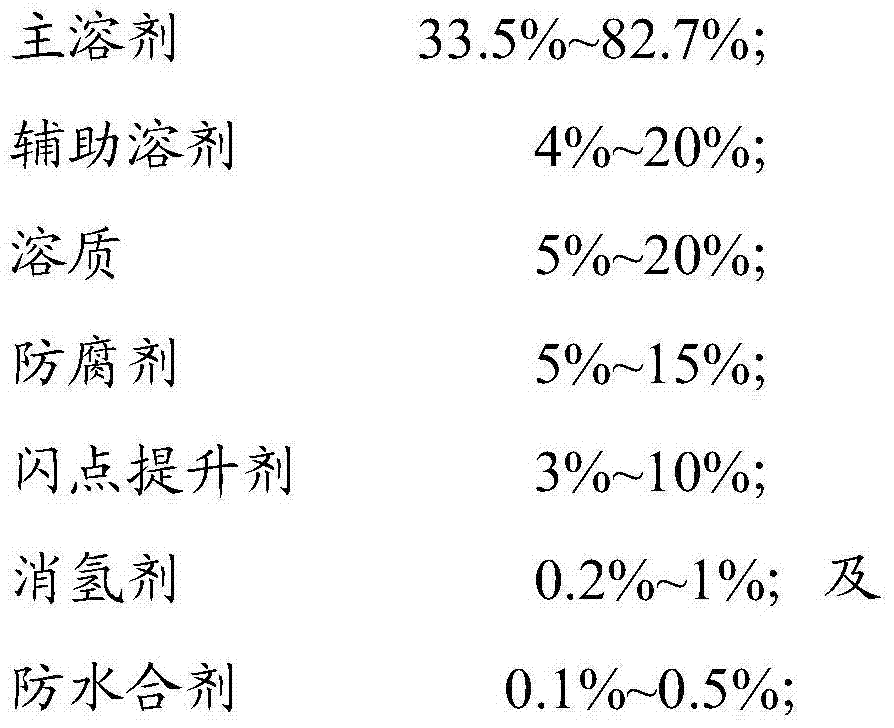

[0040] A method for preparing an electrolyte solution for an aluminum electrolytic capacitor according to an embodiment is used to prepare the electrolyte solution for the above-mentioned aluminum electrolytic capacitor, comprising the following steps:

[0041] Mix the main solvent and auxiliary solvent and heat it to 95°C-105°C, then add the solute to obtain a mixture, heat the mixture to 125°C-135°C, keep it at 125°C-135°C for 10 minutes, and cool it down to 100°C naturally Finally, add antiseptic, flash point raising agent, hydrogen extinguishing agent and water-repellent mixture, dissolve and mix evenly, cool naturally, and obtain the electrolytic solution of aluminum electrolytic capacitor.

[0042] Among them, in terms of mass percentage, the main solvent accounts for 33.5%-82.7%, the auxiliary solvent accounts for 4%-20%, the solute accounts for 5%-20%, the preservative accounts for 5%-15%, and the flash point enhancer accounts for 3%- 10%, hydrogen scavenger 0.2% to 1%...

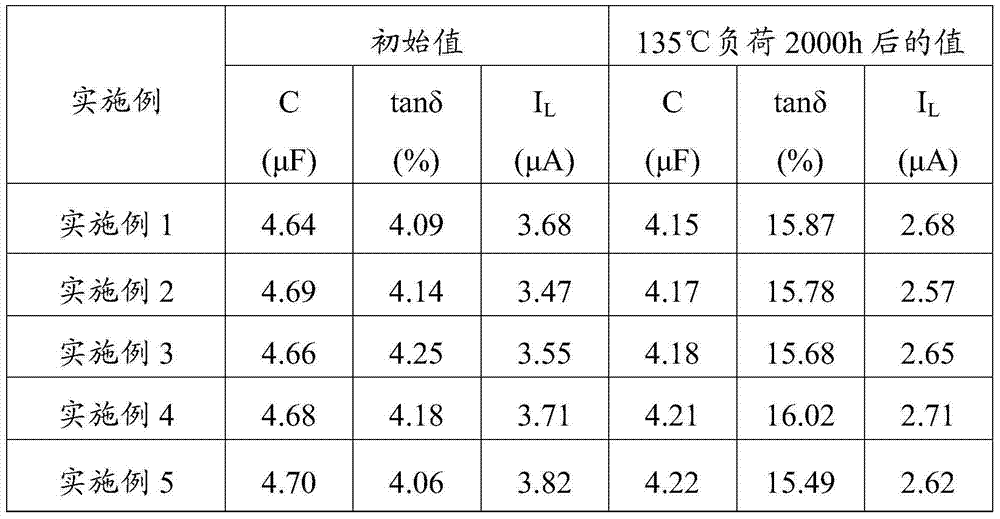

Embodiment 1

[0062] Fabrication of Aluminum Electrolytic Capacitors

[0063] 1. Mix the main solvent and the auxiliary solvent and heat it to 95°C, then add the solute to obtain the mixture, heat the mixture to 125°C, keep it at 125°C for 10 minutes, cool it down to 100°C naturally, add preservatives, flash Point enhancer, hydrogen remover and waterproof mixture, dissolved and mixed evenly, cooled naturally to obtain the electrolyte of aluminum electrolytic capacitors;

[0064] Wherein, the mass percent of main solvent, auxiliary solvent, solute, preservative, flash point raising agent, hydrogen suppressant and waterproof mixture is shown in Table 1 below.

[0065] The main solvent is ethylene glycol, the auxiliary solvent is polyethylene glycol 400, the solute is ammonium isosebacate, the preservative is ethylenediaminetetraacetic acid, the flash point enhancer is polyethylene glycol succinate, and the hydrogen remover It is p-nitrobenzoic acid, and the waterproof mixture is monobutyl ph...

Embodiment 2

[0070] Fabrication of Aluminum Electrolytic Capacitors

[0071] 1. Mix the main solvent and auxiliary solvent and heat it to 105°C, then add the solute to obtain the mixture, heat the mixture to 135°C, keep it at 135°C for 10 minutes, cool it down to 100°C naturally, add preservatives, flash Point enhancer, hydrogen remover and waterproof mixture, dissolved and mixed evenly, cooled naturally to obtain the electrolyte of aluminum electrolytic capacitors;

[0072] Wherein, the mass percent of main solvent, auxiliary solvent, solute, preservative, flash point raising agent, hydrogen suppressant and waterproof mixture is shown in Table 1 below.

[0073] The main solvent is ethylene glycol, the auxiliary solvent is a mixture of polyethylene glycol 400 and mannitol in a mass ratio of 2:1, and the solute is ammonium isosebacate and 2-butylammonium suberate (mass ratio is 1:1 ), the preservative is ethylenediaminetetraacetic acid and 8-carboxyquinoline (mass ratio is 5:2), and the fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com