High-voltage aluminium electrolysis capacitor

A technology of aluminum electrolytic capacitors and capacitors, applied in electrolytic capacitors, liquid electrolytic capacitors, capacitors, etc., can solve the problems of no high-voltage anode foil and cannot meet the needs of high-voltage capacitor production, and achieve the effect of eliminating technical hidden dangers and preventing breakdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

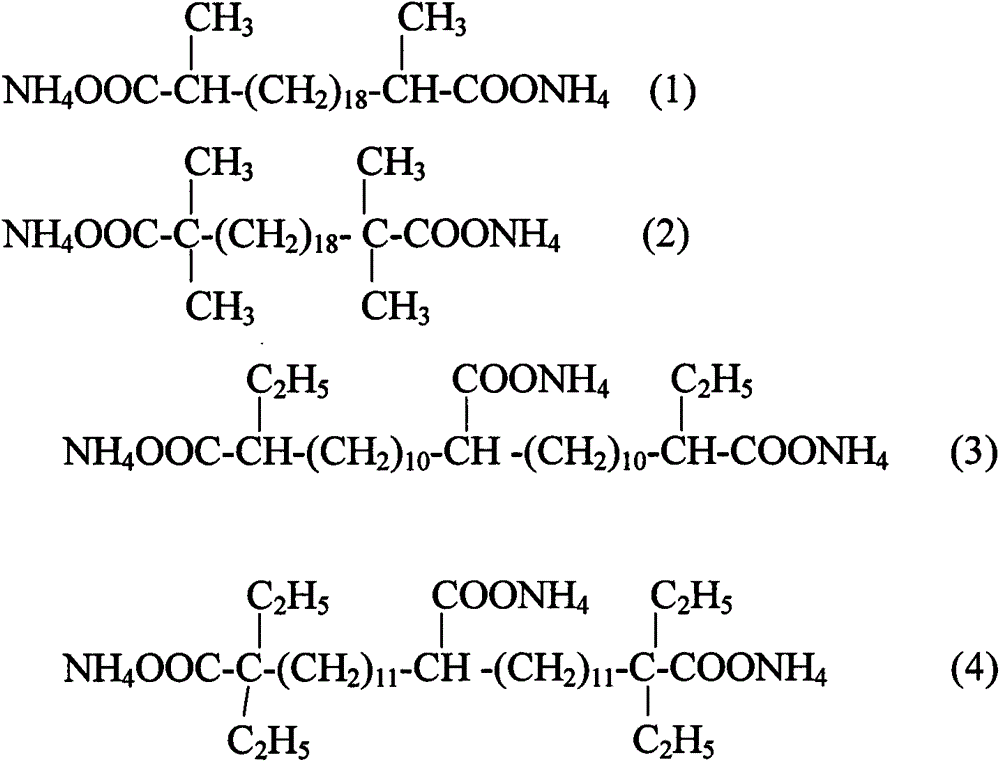

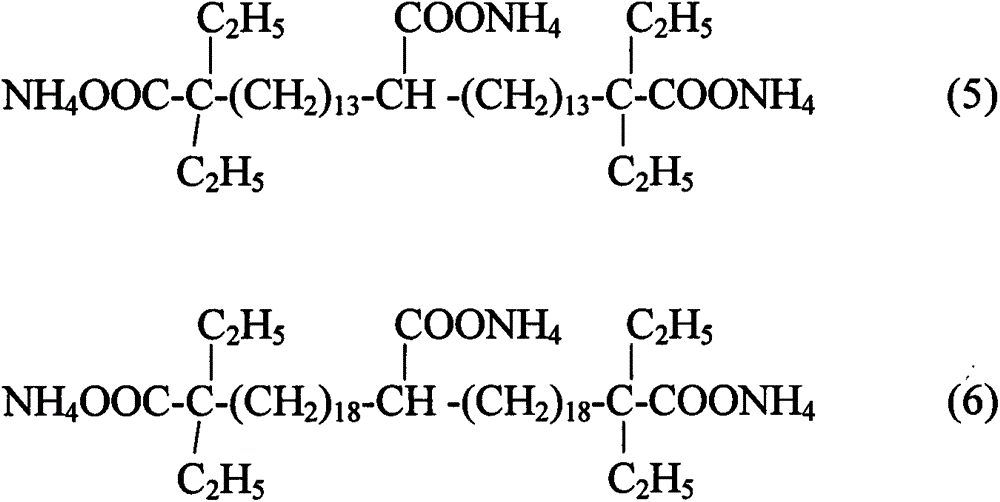

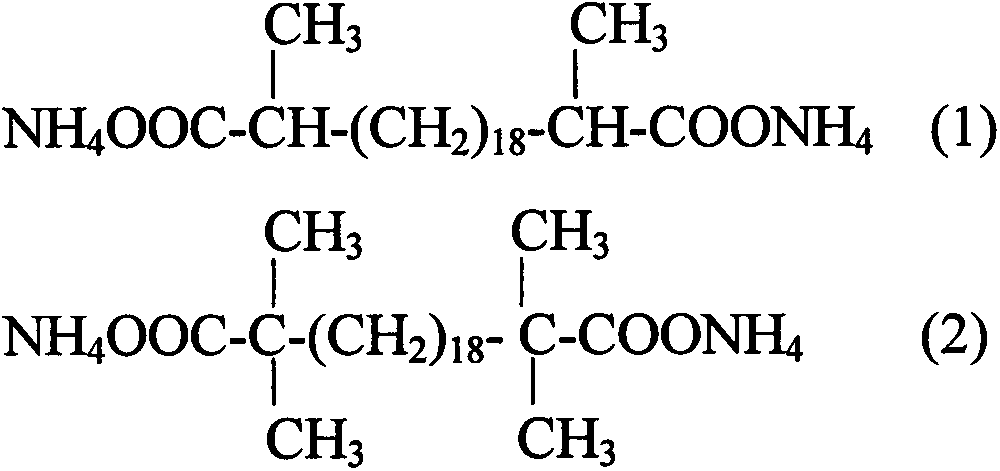

[0051] According to the usual production process, the capacitor is manufactured with a working voltage of 700V and a capacity of 6800uF. The special feature is that the anode foil is selected as the anode foil with a formation voltage of 950Vf. The composition of the electrolyte is as follows: (mass percentage, the same below):

[0052] Diethylene glycol 63%, 14% carboxylate ammonium salt described in the above (1) formula, ammonium pentaborate 10%, mannitol 12%, monobutyl phosphate 1%. The conductivity at 25°C is 0.4s / m, and its pH value at 25°C is 5.8.

Embodiment 2

[0054] This embodiment is basically the same as Embodiment 1, the difference being that the anode foil is selected as an anode foil with a formation voltage of 980Vf, and its electrolyte composition is as follows: (mass percentage, the same below):

[0055] Ethylene glycol 65%, 15% carboxylate ammonium salt described in the above (2) formula, ammonium pentaborate 8.5%, mannitol 10%, monobutyl phosphate 0.2%, nitroformic acid 1%, ammonium hypophosphite 0.3%. The conductivity at 25°C is 0.4s / m, and the pH value at 25°C is 7.2.

Embodiment 3

[0057] This embodiment is basically the same as Embodiment 1, the difference being that the anode foil is selected as an anode foil with a formation voltage of 1000Vf, and its electrolyte composition is as follows: (mass percentage, the same below):

[0058] Diethylene glycol butyl ether 75%, 8% carboxylate ammonium salt described in the above (3) formula, ammonium pentaborate 5%, mannitol 10.5%, monobutyl phosphate 0.5%, nitroformic acid 0.5%, ammonium hypophosphite 0.5% %. The conductivity at 25°C is 0.2 s / m, and its pH value at 25°C is 7.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com