Underground oil-water separation same-well injection-production system and pipe column

A technology of oil-water separation, injection and production in the same well, applied in wellbore/well components, production fluids, earth-moving drilling and production, etc., can solve the problems of increased water content of produced fluid, increased cost of gathering, transportation and sewage treatment, lifting, etc. , to achieve the effect of high lifting head and lower comprehensive development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment one (adopt above note)

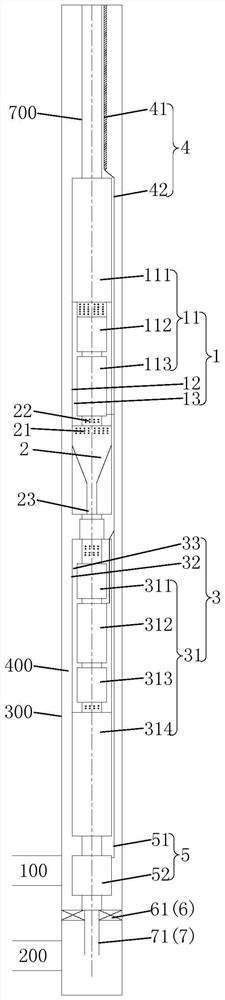

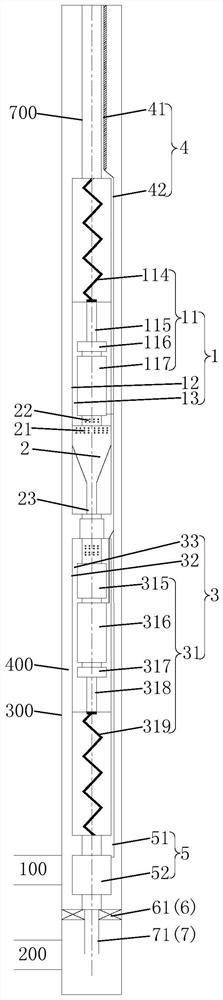

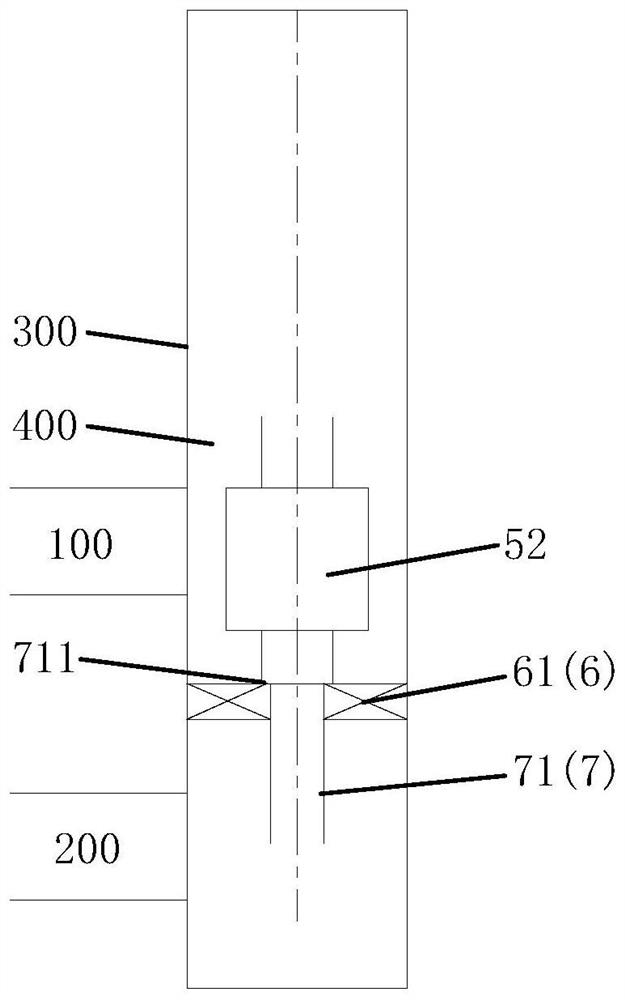

[0079] Such asfigure 1 , figure 2 , image 3 , Figure 4 As shown, in Embodiment 1, the production layer 100 is located above the water injection layer 200, and the isolation system 6 includes a first packer 61 arranged in the downhole casing 300 and located between the production layer 100 and the water injection layer 200. A packer 61 separates the production layer 100 from the water injection layer 200 to prevent the production layer 100 from colluding with the water injection layer 200. The oil jacket annulus 400 is located above the first packer 61, and the production layer 100 communicates with oil and water through the oil jacket annulus 400. The inlet 21 is connected, and the oil-water mixture in the production layer 100 flows through the oil jacket annulus 400 and the oil-water inlet 21 to enter the oil-water separation system 2; A seal is inserted between the sealing tube 71 and the first packer 61, and the upper end o...

Embodiment 2

[0083] Embodiment two (take note on)

[0084] Such as Figure 5 , Figure 6 As shown, in the second embodiment, the production layer 100 includes the first production layer 110, the water injection layer 200 includes the first water injection layer 210 above the first production layer 110, and the isolation system 6 includes the first production layer 110 and the second production layer. The second packer 62 between the first water injection layer 210 and the third packer 63 between the first water injection layer 210 and the oil jacket annulus 400; the second packer 62 and the third packer 63 Connected with the diversion system 7, there is a water injection annulus 500 between the diversion system 7 and the downhole casing 300, the water injection annulus 500 is located between the second packer 62 and the third packer 63 and is connected to the first water injection layer 210, the diversion system 7 has a water flow channel connecting the reinjection system 3 with the wa...

Embodiment 3

[0100] Embodiment three (take two ends and note the middle)

[0101] Such as Figure 11 As shown, in the third embodiment, the production layer 100 includes the first production layer 110 and the second production layer 120, the water injection layer 200 includes the first water injection layer 210, the first water injection layer 210 is located above the first production layer 110, the second Below the production layer 120, the downhole oil-water separation injection-production system in the third embodiment includes all the technical features of the second embodiment, and also includes the following technical features: the third packer 63 is located below the second production layer 120, and the second production The oil-water mixture in the layer 120 flows through the oil jacket annulus 400 and the oil-water inlet 21 into the oil-water separation system 2 in sequence.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com