Preparation method of dioctyl sodium sulfosuccinate

A technology of diisooctyl sulfonate sodium succinate and diisooctyl butenedioate, which is applied in the fields of sulfonic acid preparation, sulfonate preparation, organic chemistry, etc., and can solve the problem of inability to obtain diisooctyl sulfonate succinate Sodium acid sodium products, limited use range of penetrant products, difficult to guarantee the residual amount of isooctyl alcohol, etc., to achieve the effect of enhancing the effect of reflux alcohol removal, reducing the total feeding amount, and reducing the residue of isooctyl alcohol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Put 267Kg of isooctyl alcohol and 98Kg of maleic anhydride into the esterification reaction kettle, feed nitrogen, start stirring, heat up to 80°C and keep it for 1.5 hours, add 4Kg of dibutyltin oxide, 3Kg of sodium phosphite, and heat up to 115 Keep warm at ℃ for 1.5 hours, continue to heat up, and keep warm for 4 hours after reaching 200 ℃, cool the material to 60 ℃, and filter with 1 μ filter cloth to obtain diisooctyl butenedioate.

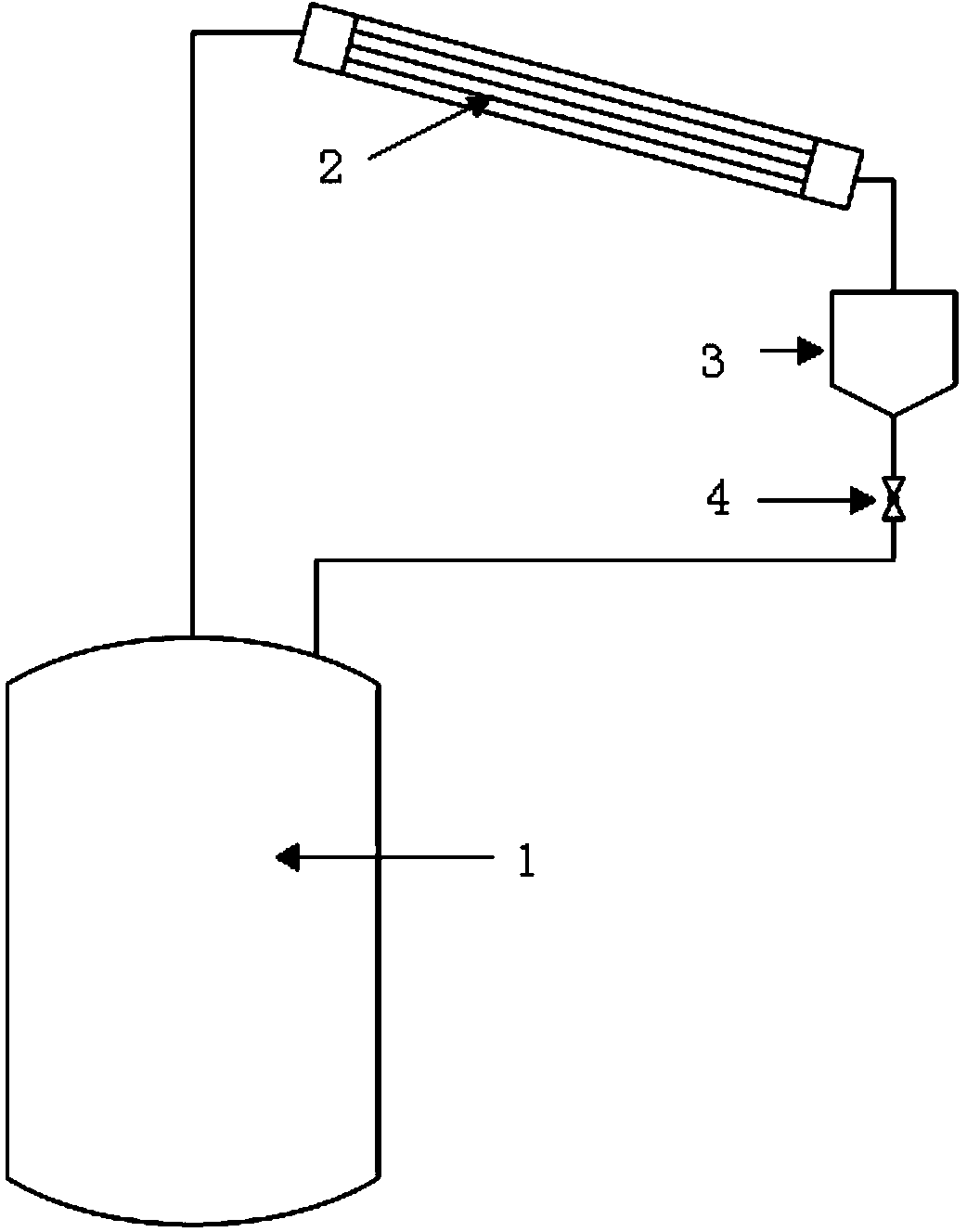

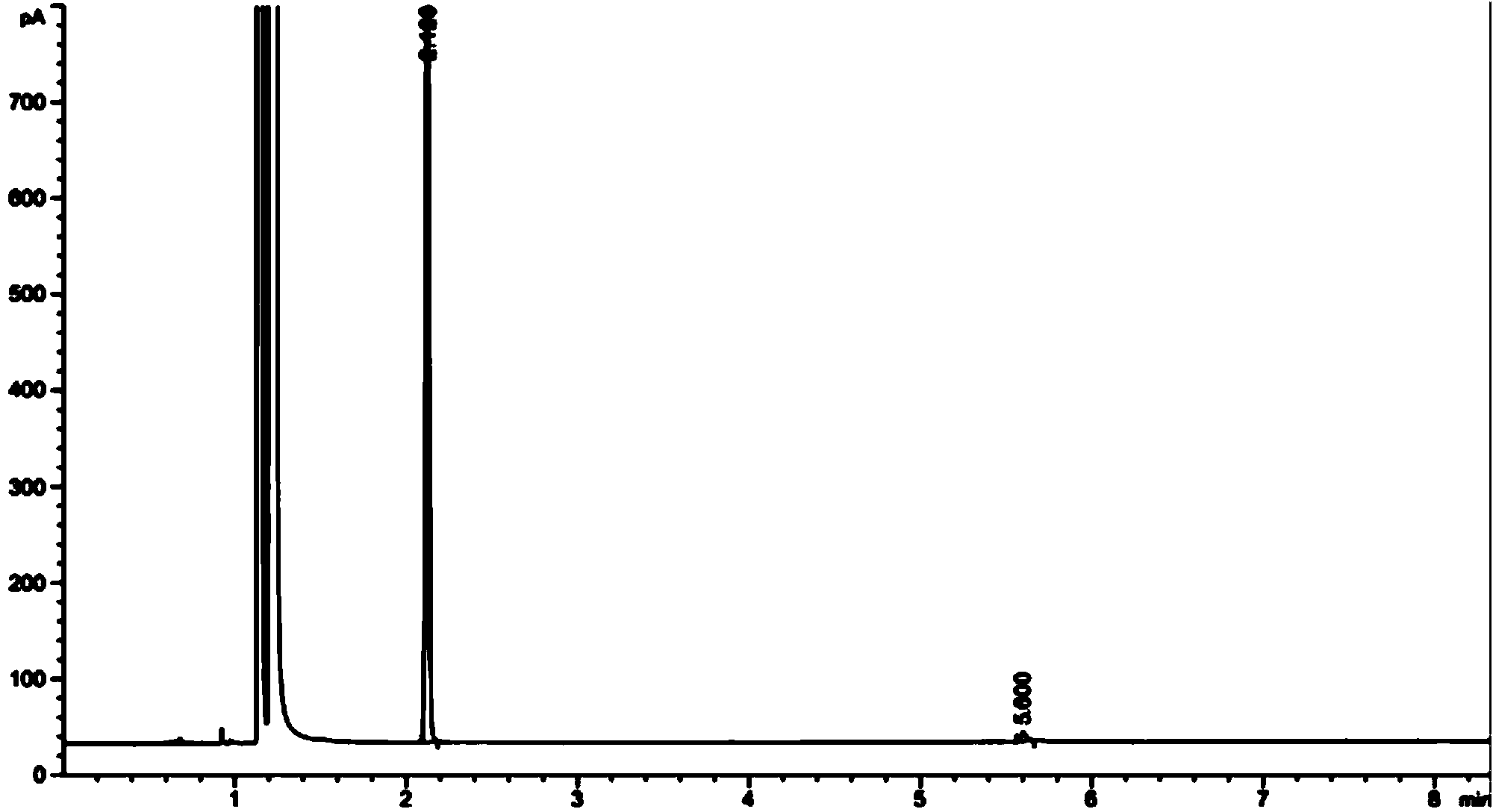

[0040] Put 340Kg of diisooctyl butenedioate and 130Kg of water into the sulfonation reactor 1, start stirring, neutralize with sodium hydroxide until the acid value is 0-0.3mgKOH / g, add 108Kg of sodium bisulfite, open Condensate water and heat up to 110-115°C for reflux reaction. Sulfonation reaction equipment such as figure 1 As shown, observe the total amount of liquid condensed by the condenser 2 through the liquid level gauge of the reflux header tank 3, control the lower reflux control valve 4, and only return the water in the lo...

Embodiment 2

[0042] Put 273Kg of isooctyl alcohol and 98Kg of maleic anhydride into the esterification reaction kettle, feed nitrogen, start stirring, heat up to 90°C and keep it warm for 1 hour, add 3Kg of boric acid, 1Kg of phosphoric acid, 3Kg of sodium hypophosphite, and heat up to 115°C Keep warm for 2 hours, continue to heat up, and keep warm for 4.5 hours after reaching 200°C, cool the material to 60°C, and filter with 1μ filter cloth to obtain diisooctyl butenedioate.

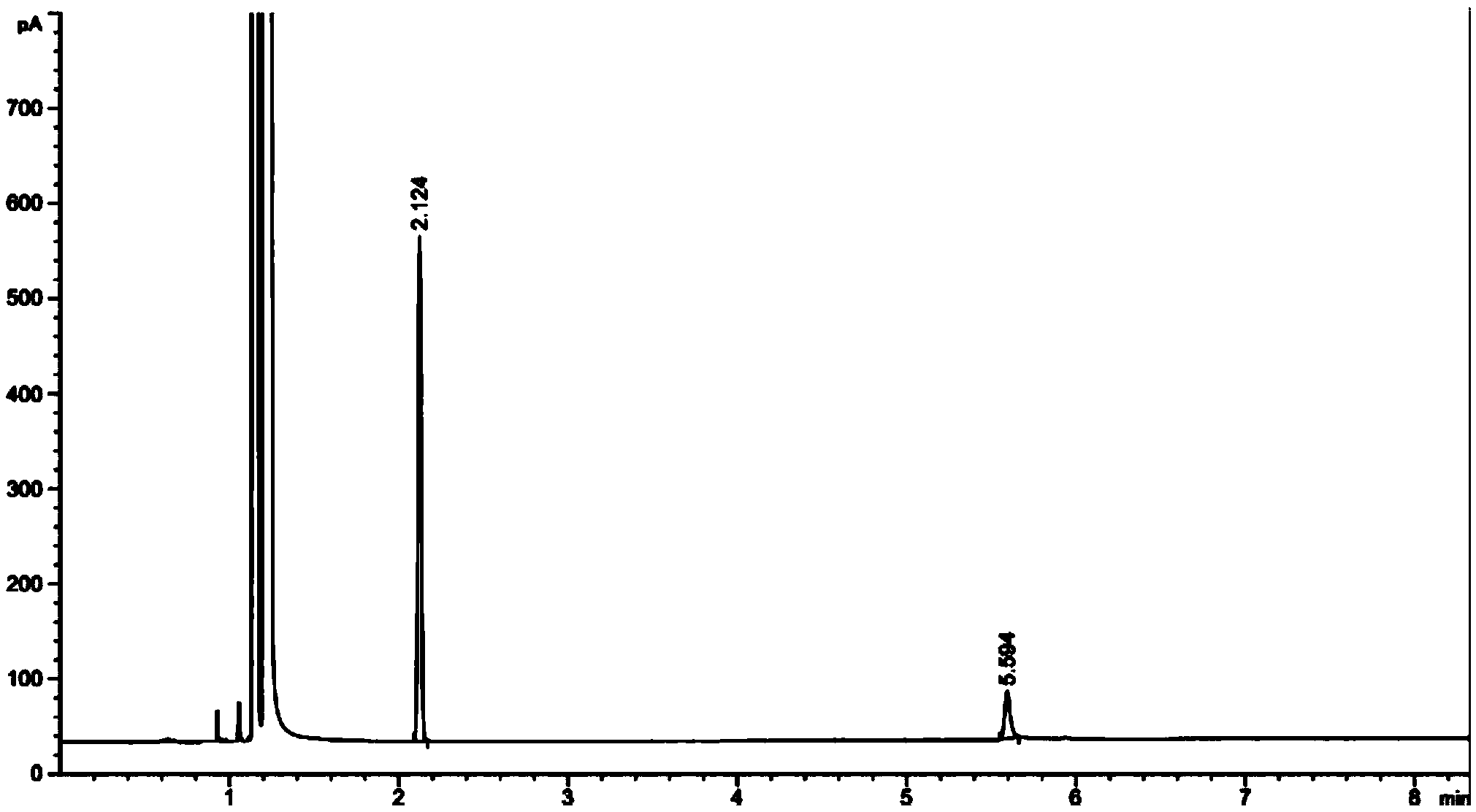

[0043]Put 340Kg of diisooctyl butenedioate and 120Kg of water into the sulfonation reactor 1, start stirring, neutralize with sodium hydroxide until the acid value is 0-0.3mgKOH / g, add 110Kg of sodium bisulfite, open Condensate water and heat up to 110-115°C for reflux reaction. Through the liquid level gauge of the reflux header tank 3, observe the total amount of liquid condensed by the condenser 2, control the lower reflux control valve 4, and only return the water in the lower layer of the reflux header tank 3, ...

Embodiment 3

[0045] Put 260Kg of isooctyl alcohol and 98Kg of maleic anhydride into the esterification reaction kettle, blow in nitrogen, start stirring, raise the temperature to 60°C and keep it for 2 hours, add 0.1Kg of p-toluenesulfonic acid, 0.1Kg of loaded phosphotungstic acid, 2Kg Hypophosphorous acid, heat up to 115°C and keep warm for 3 hours, continue to heat up, and keep warm for 5 hours after reaching 185°C, cool the material to 60°C, filter with 1 μ filter cloth to obtain diisooctyl butenedioate.

[0046] Put 340Kg of diisooctyl butenedioate and 89Kg of water into the sulfonation reactor 1, start stirring, neutralize with sodium hydroxide until the acid value is 0-0.3mgKOH / g, add 104.1Kg of sodium bisulfite, and start Large condensed water, heated to 110 ~ 115 ° C for reflux reaction. Through the liquid level gauge of the reflux header tank 3, observe the total amount of liquid condensed by the condenser 2, control the lower reflux control valve 4, and only return the water in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com