Oil refining and chemical sewage processing and recovering equipment and method thereof

A technology for chemical sewage and recovery equipment, applied in water/sewage treatment equipment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve the problem of sewage discharge treatment not completely solved, concentrated water cannot be discharged up to standard, and discharge is not allowed And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

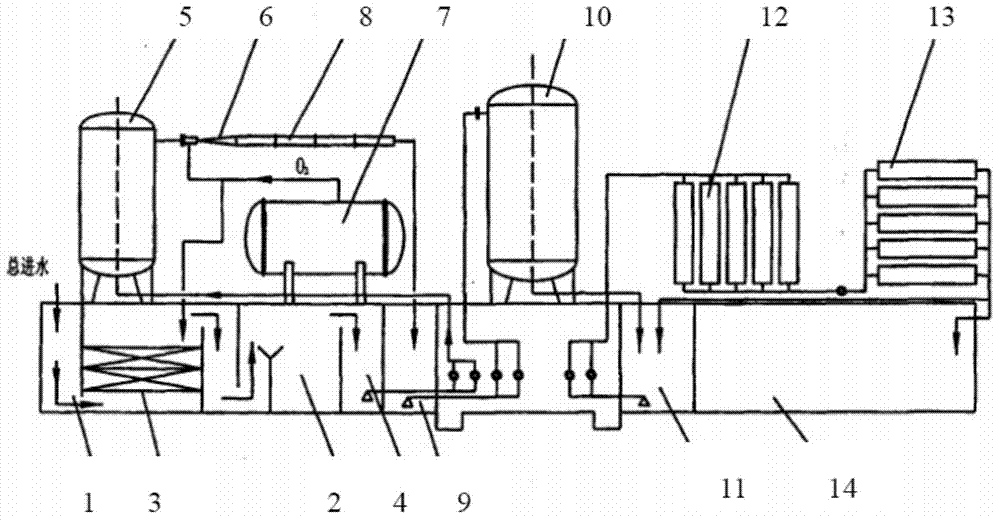

[0044] Such as image 3 As shown in the figure, the oil refining and chemical sewage recovery and utilization equipment for implementing the method according to the first embodiment of the present invention are shown. The equipment includes a mixing reaction tank 1 connected in sequence, an anti-blocking air flotation tank 2, and a multi-stage Equipped with biofilter 3, clear water pool 4, high-efficiency precision filter 5, jet device 6, ozone generator 7, mixer 8, intermediate pool 9, biological activated carbon filter 10, water purification pool 11, if the reuse water does not need desalination It can be used in industrial pipe network. If desalination is required, hollow ultrafiltration membrane (or hollow microfiltration membrane) 12, RO reverse osmosis membrane 13 and desalinated water pool 14 are added.

[0045] The working process of the oil refining and chemical sewage recycling equipment of embodiment 1 of the present invention is as follows Figure 4 Shown:

[00...

Embodiment 2

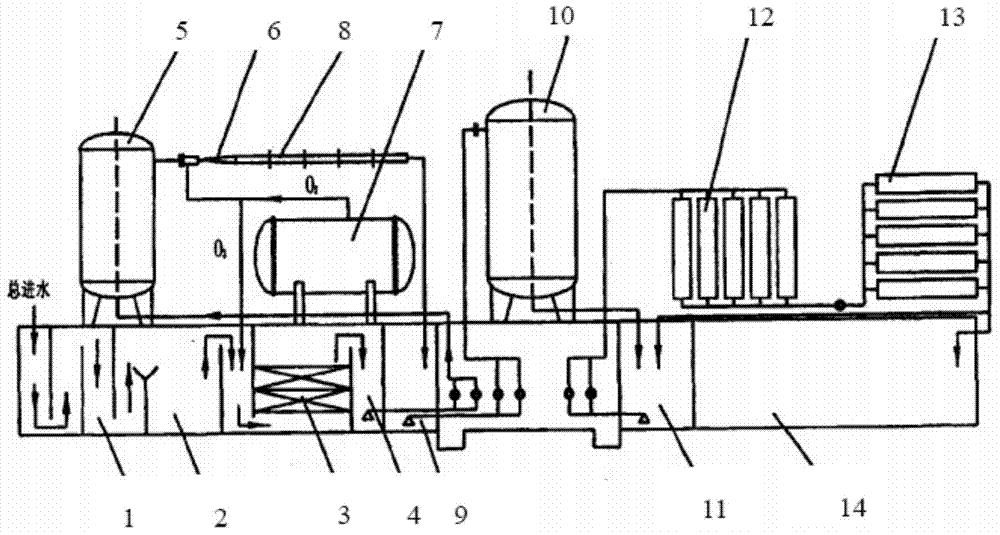

[0052] Such as figure 2 As shown in the figure, the oil refining and chemical sewage recycling equipment for implementing the method according to the second embodiment of the present invention is shown, and the equipment includes a mixing reaction tank 1 connected together in sequence, a multi-stage biofilter 3, Air flotation pool 2, clear water pool 4, high-efficiency precision filter 5, jet device 6, ozone generator 7, mixer 8, intermediate pool 9, biological activated carbon filter 10, water purification pool 11, if the reused water can be fed without desalination The industrial pipe network is used. If desalination is required, hollow ultrafiltration membrane (or hollow microfiltration membrane) 12, RO reverse osmosis membrane 13 and desalinated water pool 14 are added.

[0053] The working process of the oil refining and chemical sewage recycling equipment of embodiment 2 of the present invention is as follows Figure 5 Shown:

[0054] a. After the secondary treatment...

Embodiment 3

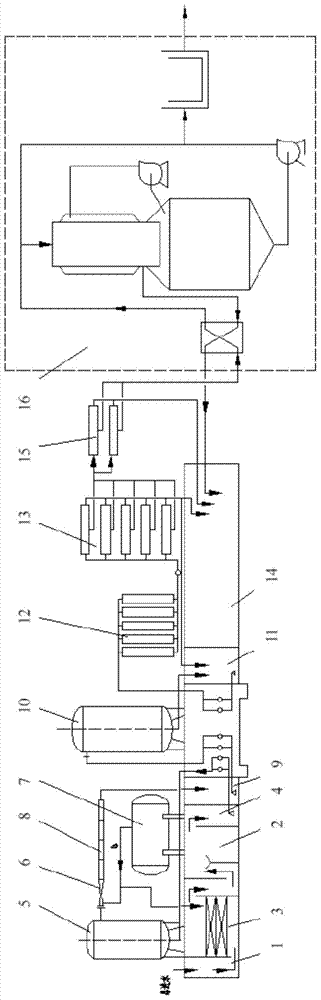

[0060] Such as figure 1 As shown in the figure, the oil refining and chemical sewage recycling equipment for implementing the method according to the third embodiment of the present invention is shown, and the equipment includes a mixing reaction tank 1 connected together in sequence, a multi-stage biofilter 3, Anti-blocking air flotation pool 2, clear water pool 4, high-efficiency precision filter 5, jet device 6, ozone generator 7, mixer 8, intermediate pool 9, biological activated carbon filter 10, water purification pool 11, hollow ultrafiltration membrane (or hollow Microfiltration membrane) 12, RO reverse osmosis membrane 13, desalinated water tank 14, reverse osmosis (nanofiltration) membrane 15, mechanical vapor compression system 16.

[0061] The working process of the oil refining and chemical sewage recycling equipment of embodiment 3 of the present invention is as follows Image 6 Shown:

[0062] a. The secondary treated oil refining and chemical sewage enters th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com