Method for increasing yield of oil well through combined application of gel foam and in-situ micro-emulsion

A technology of gel foam and microemulsion, which is applied in drilling compositions, chemical instruments and methods, earthwork drilling and production, etc. It can solve the problem of not improving the efficiency of water flooding and washing oil, expanding the swept volume, and dealing with the effect of oil well increase and other problems, to achieve the effect of strong ability to solubilize crude oil, obvious effect and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following examples further illustrate the content of the present invention, but should not be construed as limiting the present invention. Without departing from the spirit and essence of the present invention, any modifications or substitutions made to the methods, steps or conditions of the present invention fall within the scope of the present invention.

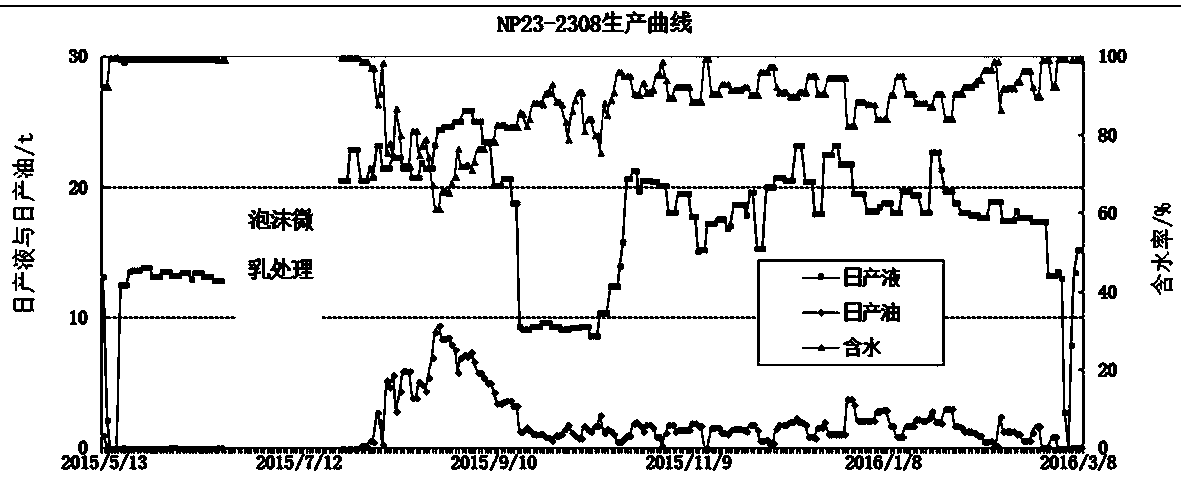

[0027] 1. Field effect of combined application of gel nitrogen foam system and in-situ microemulsion system slug

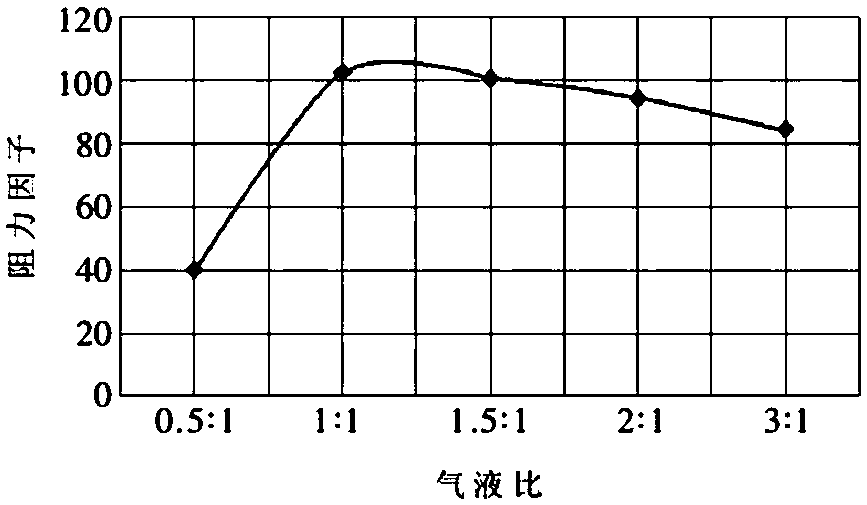

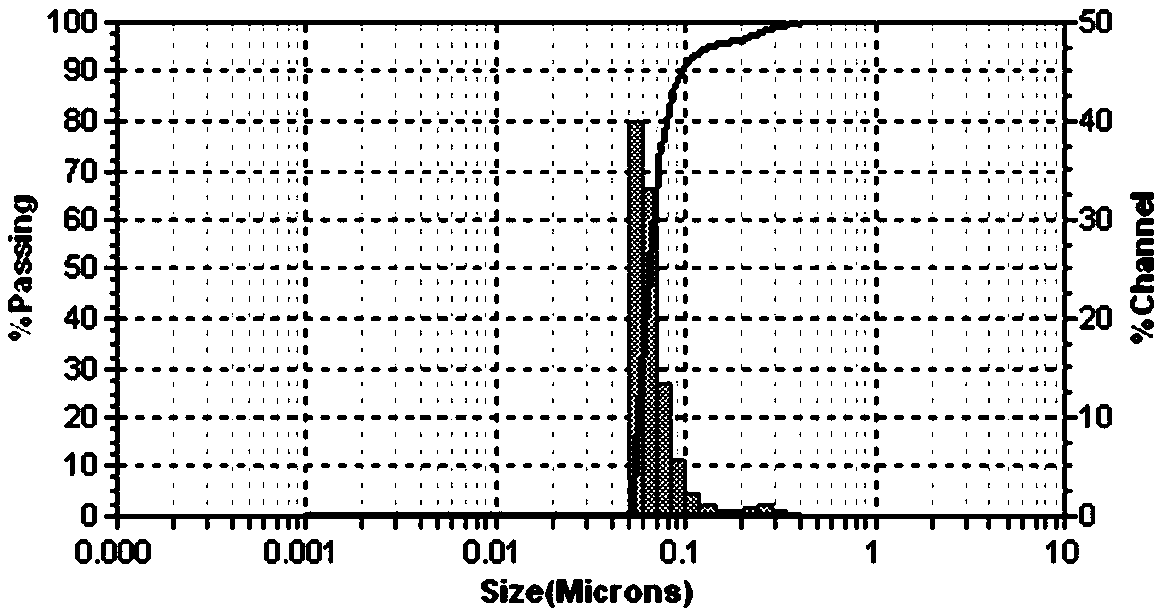

[0028] There are many types of edge water and bottom water reservoirs in Jidong Nanpu Oilfield of PetroChina, and the reservoir heterogeneity is serious. Due to water channeling, edge water immersion and bottom water coning, the water cut of oil wells rises sharply in the early stage of natural energy opening of the oilfield. Seriously affect the oilfield development effect. The reservoir and development parameters of the oil well in the present invention are reservoir temperature of 50-100°C, por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com