Multi-channel reservoir physical model of heavy oil thermal production well to be constructed and application thereof

A physical model and well construction technology, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of less related reports and less research, and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

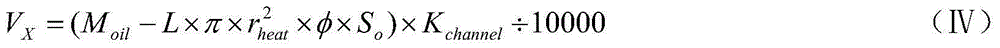

[0122] Using the physical model of the present invention, the indoor simulation experiment and construction design before the plugging construction of the heavy oil thermal recovery production well A1 in an oil field are carried out. The maximum permeability of the reservoir of the A1 well to be constructed is 500mD, and the minimum permeability is 100mD. 6 rounds have been produced, and the construction design and implementation effect of this well are taken as an example to illustrate the method of utilizing the physical model of the present invention and the simulation experiment method to carry out construction design. The specific process is as follows:

[0123] (1) Establishment of multi-channel reservoir physical model for heavy oil thermal recovery wells to be constructed

[0124] Formation sand, crude oil and formation water samples produced in Well A1 were used to establish a multi-channel physical model of the reservoir in the construction well of heavy oil thermal r...

Embodiment 2

[0164] Using the physical model of the present invention, the indoor simulation experiment and construction design before the plugging construction of the heavy oil thermal recovery production well A2 in an oil field are carried out. The maximum permeability of the reservoir of the A2 well to be constructed is 1000mD, and the minimum permeability is 300mD. 4 rounds have been produced, and the construction design and implementation effect of this well are taken as an example to illustrate the method of utilizing the physical model of the present invention and the simulation experiment method to carry out construction design. The specific process is as follows:

[0165] (1) Establishment of multi-channel reservoir physical model for heavy oil thermal recovery wells to be constructed

[0166] Formation sand, crude oil, and formation water samples from Well A2 were used to establish a reservoir physical model for the construction well of heavy oil thermal recovery sealing channelin...

Embodiment 3

[0206] Utilize the physical model of the present invention to carry out the indoor simulation experiment and construction design before the plugging construction of the A3 well of heavy oil thermal recovery production well in an oil field, the maximum permeability of the reservoir of the A3 well to be constructed is 800mD, and the minimum permeability is 100mD. Production 2 rounds, take the construction design and implementation effect of this well as an example to illustrate the method of utilizing the physical model of the present invention and the simulation experiment method to carry out construction design, and the specific process is as follows:

[0207] (1) Establishment of multi-channel reservoir physical model for heavy oil thermal recovery wells to be constructed

[0208] Formation sand, crude oil and formation water samples from Well A3 were used to establish a reservoir physical model for the construction well of heavy oil thermal recovery sealing channeling and wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com