Method for determining real-time steering fracturing parameters based on composite temporary plugging system

A parametric and systematic technology, applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of high pertinence and effectiveness of difficult fracturing schemes, uniform reconstruction of difficult horizontal well sections, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for determining real-time diversion fracturing parameters based on a composite temporary plugging system. The aim is to increase the complexity of the fracture network in the reconstruction of the horizontal section and achieve uniform reconstruction of the horizontal section. The real-time steering fracturing technology uses a composite temporary plugging system including soluble temporary plugging balls and temporary plugging particles to achieve temporary plugging of perforation holes and fractures of different scales, and at the same time comprehensively analyzes data such as geological parameters, construction pressure, and microseismic real-time monitoring , to form a real-time optimization of the amount, timing and frequency of the composite temporary plugging material, realize uniform reconstruction of the horizontal section, and increase the complexity of the fracturing fracture network. The real-time steering fracturing techno...

Embodiment 2

[0100] As a beneficial and preferred embodiment of the present invention, this embodiment discloses a real-time diversion fracturing technology based on a composite temporary plugging system. The specific implementation steps mainly include two aspects: real-time evaluation of composite temporary plugging effect and real-time optimization technology of temporary plugging parameters.

[0101] (1) Examples of real-time evaluation methods for composite temporary plugging effects mainly include construction pressure evaluation methods and microseismic event coverage evaluation methods.

example

[0103] During the fracturing process of stage i of shale gas well E1 in block W, the construction displacement before and after the temporary plugging agent is put in is Q1m 3 / min, the stable construction pressure before delivery is p t1 MPa, the construction pressure is stable at p after putting in t2 MPa, the temporarily blocked steering pressure is (p t2 -p t1 ) MPa.

[0104] ②Prediction example of the number of effective holes

[0105] Assuming that the perforation shape is a short cylindrical channel, the perforation friction is:

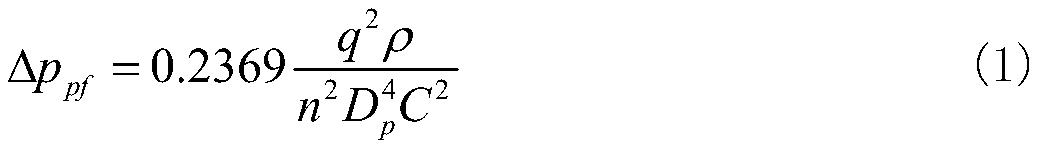

[0106]

[0107] Liquid friction calculation:

[0108]

[0109] Frictional resistance along the clear water △p w The calculation of:

[0110] For turbulent flow, a=(log 10 n+3.93) / 50,b=(1.75-log 10 n) / 7, for Newtonian fluid, n=1. Calculation of friction along the clear water:

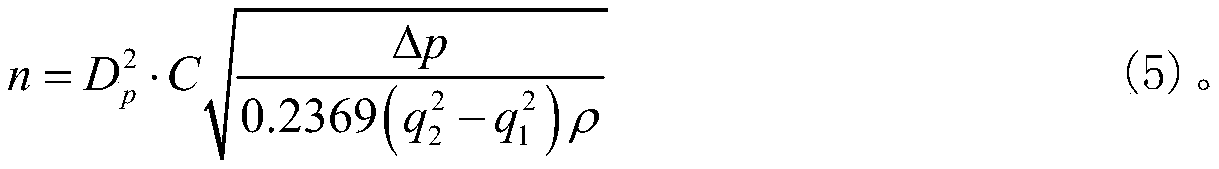

[0111] Calculation of the number of effective holes:

[0112] Perform at least two different displacements (q 1 ,q 2 ) in the pumping phase, the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com