Method and device for evaluating fracturing fluid flowback capacity of shale staged fracturing horizontal well

A staged fracturing and fracturing fluid technology, which is applied in the directions of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve problems that cannot guide shale development well and have no shale staged fracturing The fracturing fluid flowback ability evaluation method and device of fractured horizontal wells, etc., to achieve the effect of increasing the production of shale gas wells and improving the stimulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

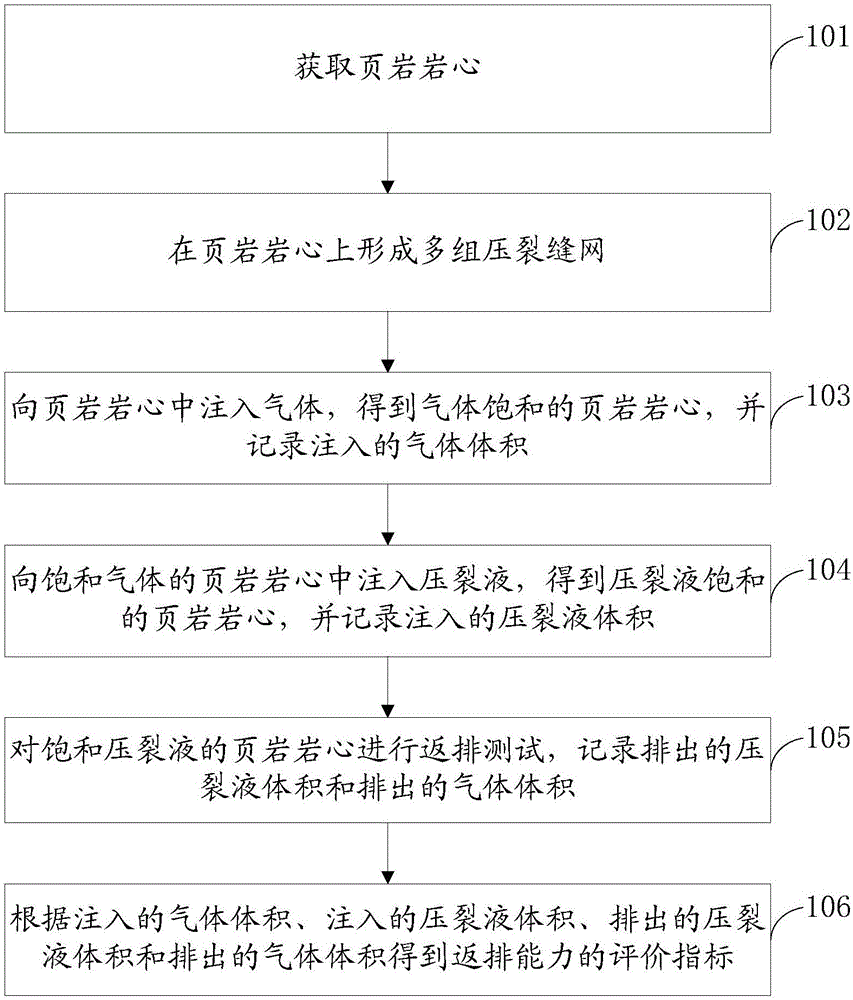

[0049] The embodiment of the present invention provides a shale staged fracturing horizontal well fracturing fluid flowback ability evaluation method and device, the following will combine specific implementation methods, such as figure 1 The processing flow shown is described in detail, and the method includes:

[0050] Step 101: obtaining a shale core;

[0051] Specifically, several shale cores collected in the field are obtained.

[0052] Step 102: forming multiple sets of fracturing fracture networks on the shale core;

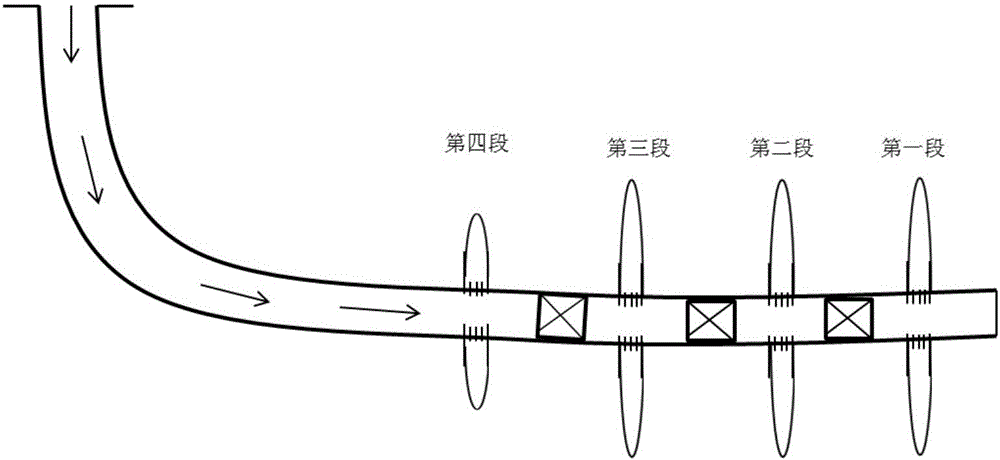

[0053]Specifically, the test should be carried out according to the status of the actual staged fracturing horizontal well in shale. At present, shale gas development mainly adopts staged multi-stage fracturing technology for horizontal wells. The entire horizontal well section is segmented through chemical isolation, mechanical isolation or special control, and the entire horizontal section is realized by stage-by-stage fracturing. remodel. Mechanical...

Embodiment 2

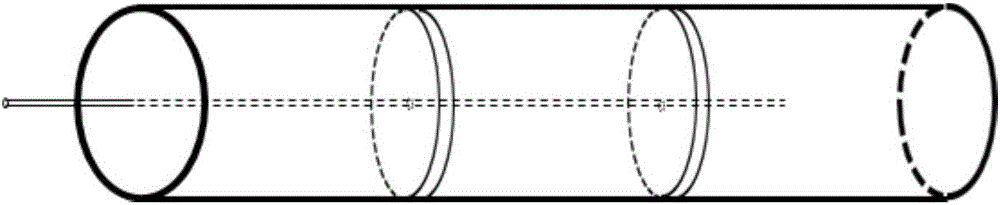

[0081] This embodiment provides a shale staged fracturing horizontal well fracturing fluid flowback mechanism test device, such as Figure 4 As shown, it includes a constant temperature box, a core holder, a fracturing fluid container, a gas container, a hydraulic pump, a confining pressure pump, a measuring cylinder, a flow meter, a first pressure gauge, and a second pressure gauge;

[0082] Specifically, the hydraulic pump is respectively connected to one end of the fracturing fluid container and one end of the gas container through a pipeline, and the other end of the fracturing fluid container and the other end of the gas container are connected to the first end of the core holder through a pipeline, and the core holder The second end of the holder, the measuring cylinder and the flowmeter are connected in turn through pipelines, the confining pressure pump is connected with the third end of the core holder, and the first pressure gauge and the second pressure gauge are loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com