Reselection recovery method and device for gold

A recovery method and magnetic separator technology, applied to chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of increasing grinding costs and affecting flotation indicators, so as to improve the recovery rate of gravity separation and reduce labor The effect of increasing the strength and the total recovery rate of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are further detailed descriptions of the present invention.

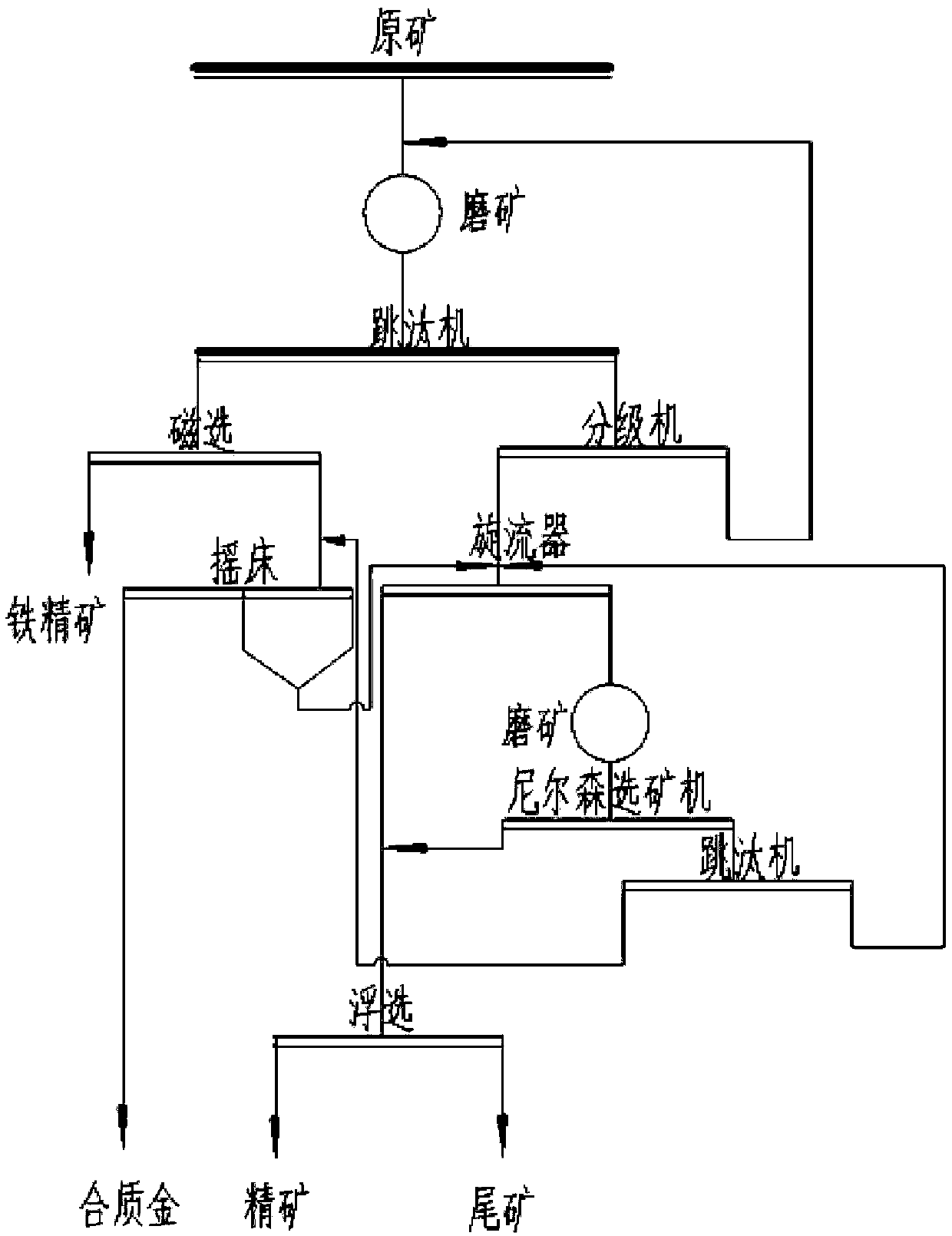

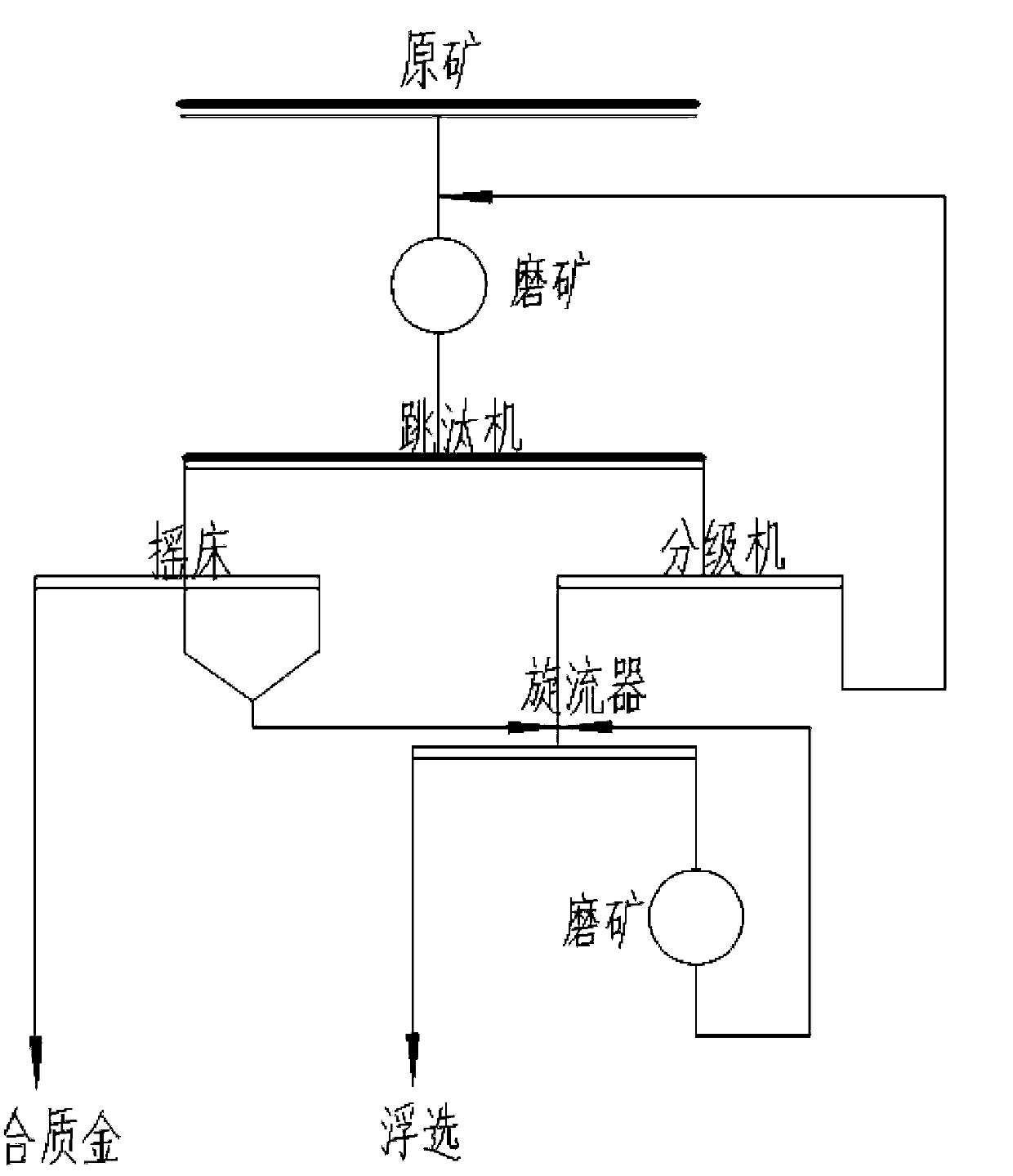

[0026] The connection relation between each equipment of the present invention is as follows:

[0027] The outlet of the grinding machine is connected to the inlet of the jig machine, the outlet of the jig machine is connected to the inlet of the magnetic separator, the concentrate of the magnetic separator is iron concentrate, and the tailings outlet of the magnetic separator is connected to the inlet of the shaker;

[0028] Shaking table concentrate is exported for smelting, which is smelted into high-quality gold, and the tailings in the shaking table are connected to the cyclone import;

[0029] The outlet of the jig tailings is connected to the inlet of the classifier, the overflow of the classifier is connected to the inlet of the cyclone, and the outlet of the classifier is connected to the inlet of a grinding machine;

[0030] The overflow outlet of the cyclone is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com