Judgment method for high temperature corrosion degree of boiler water cooling wall in large power station

A technology for high-temperature corrosion and power plant boilers, applied in combustion methods, combustion chambers, outer covers/linings, etc., can solve problems such as long maintenance periods, safety accidents, and high maintenance costs, and achieve the effect of ensuring uniqueness and overcoming limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

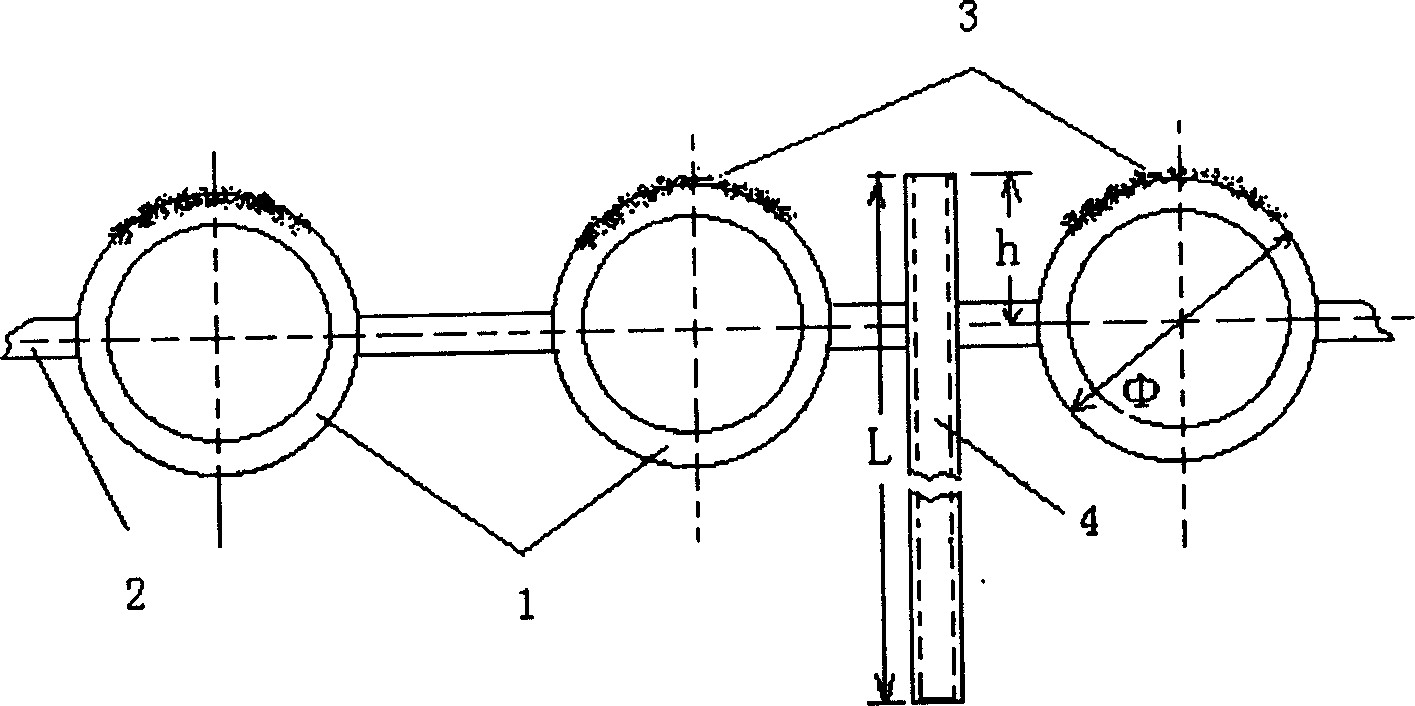

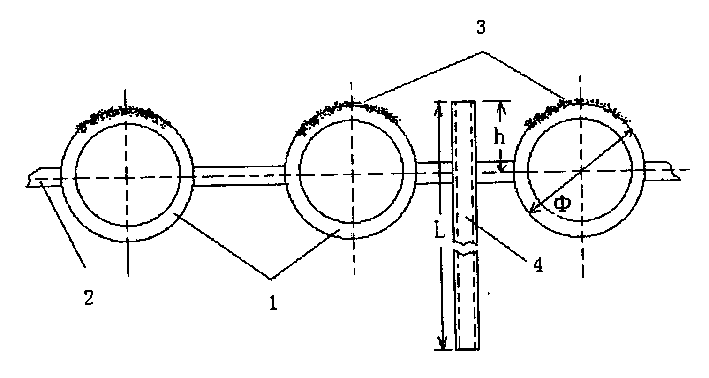

[0025] Hunan Shimen Power Plant installed 2×300MW units. During the overhaul of the №1 boiler in 1999, serious high-temperature corrosion was found in the water wall around the high-load area of the burner. The results of the wall thickness measurement show that the design specification of the water-cooled wall tube is φ63.5×8mm, the wall thickness of the severely corroded part is only 6.8-7.1mm, and the thickness has been reduced by 0.9-1.2mm, and the corrosion rate is about 0.7-1.3mm / (10 4 ) h. If the development continues at this speed, large-area water-cooled wall explosion and leakage accidents may occur in recent years. Therefore, it is imminent to analyze and study its high-temperature corrosion mechanism and main influencing factors as soon as possible, seek the best technical way to solve the problem, and improve the safety and reliability of the boiler heating surface.

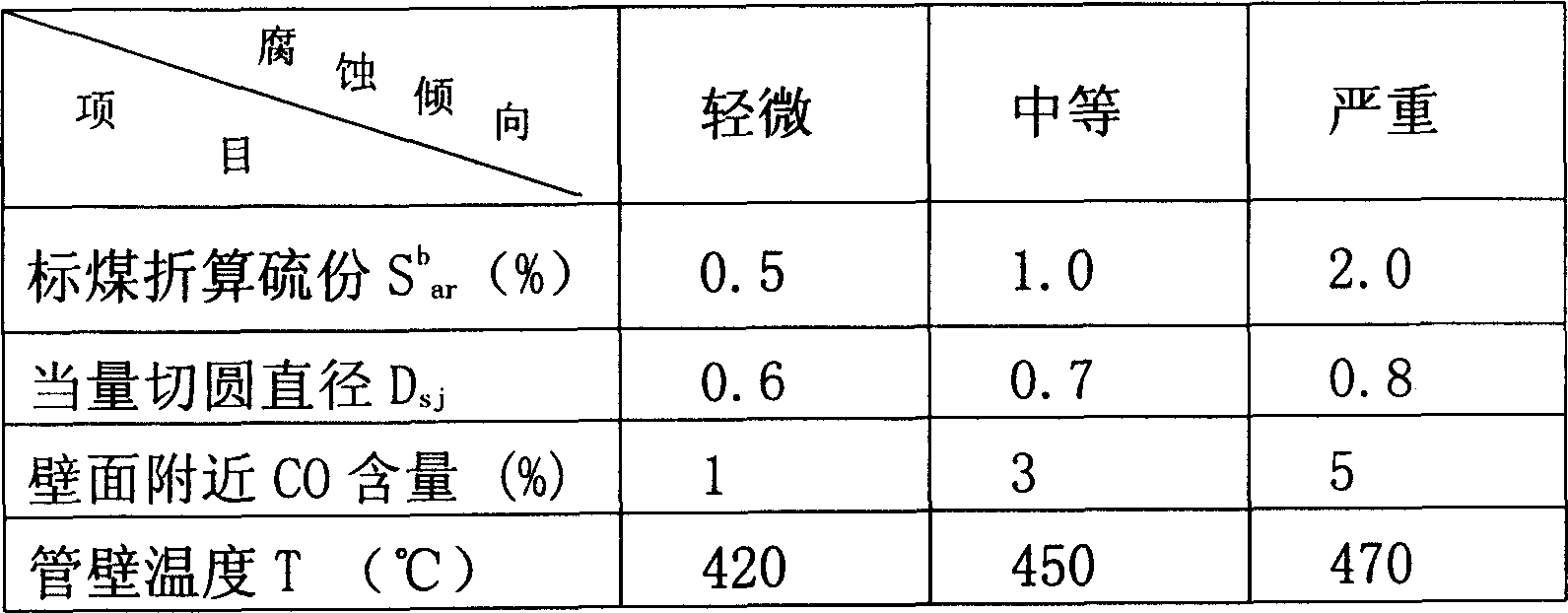

[0026] Firstly, determine the four major influencing factors of high temperature corrosion: Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com