Hydraulic sand jet perforation, fracture and sand filling integrated technological method

A process method and hydraulic jetting technology, which are applied in earth-moving drilling, production of fluids, wellbore/well components, etc., can solve the problems of reduced construction efficiency, easy damage of packers, and inability to meet construction techniques, and improve the transformation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The oil well is 3500m deep, with upper and lower oil layers, the inner diameter of the casing is 124.3mm, and the outer diameter of the tubing is 73.03mm;

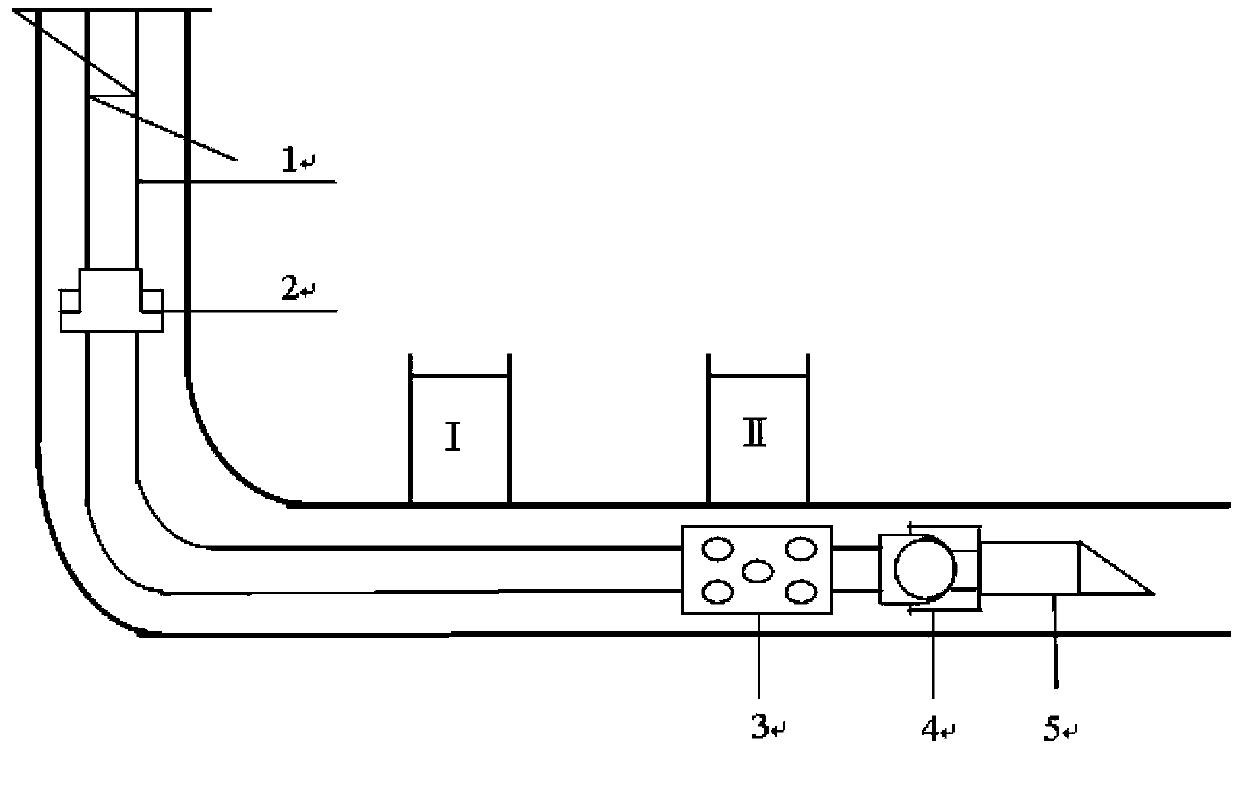

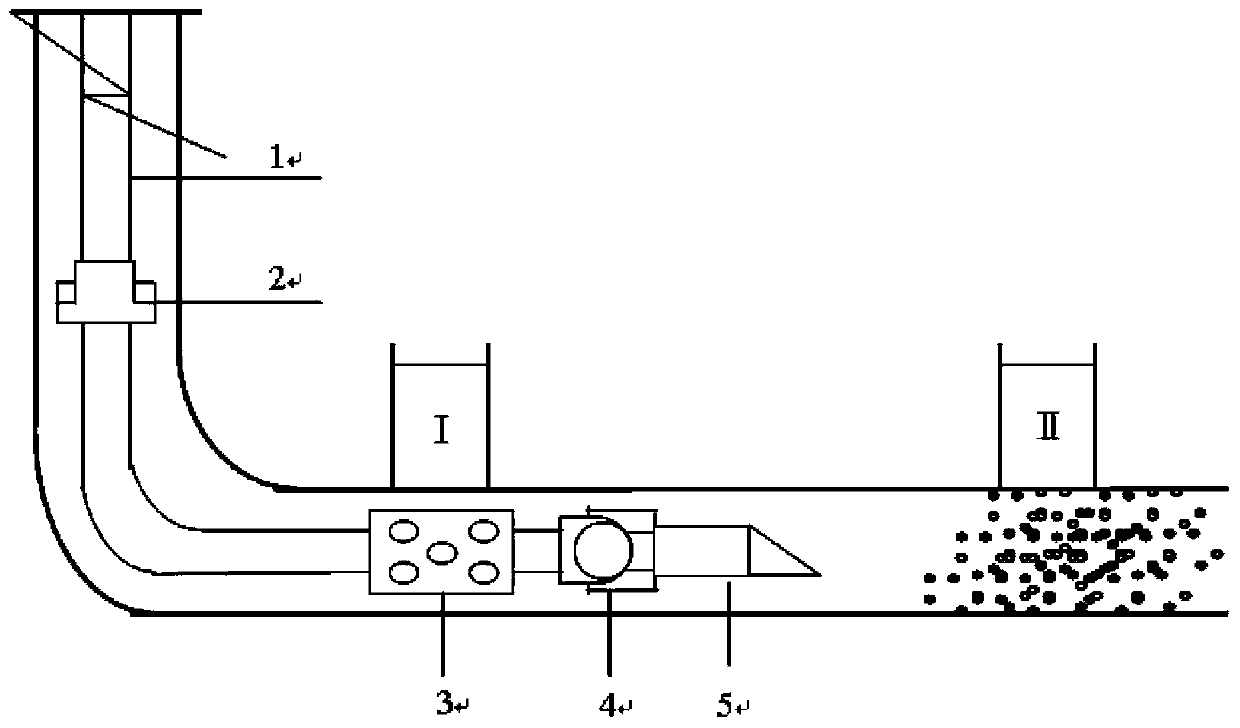

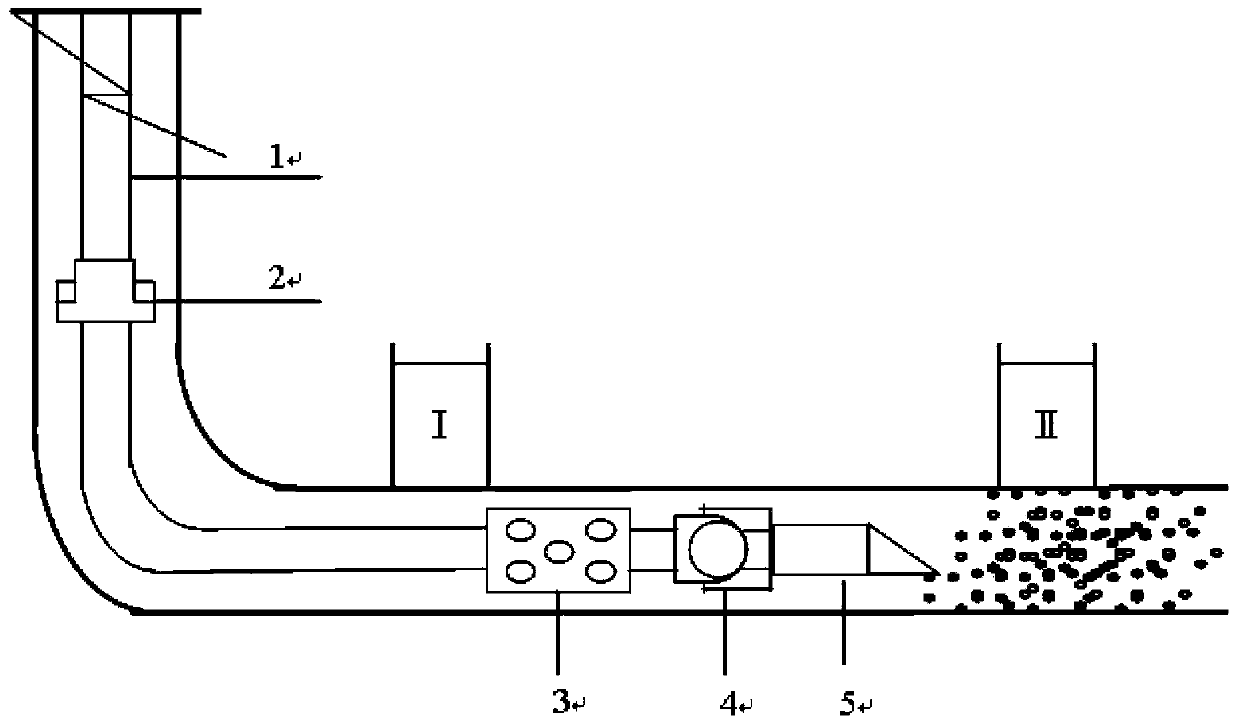

[0021] This method uses hydraulic sand blasting perforation and fracturing process pipe string operations, and the pipe string is connected to the safety joint 2, the hydraulic injector 3, the check valve 4 and the inclined tip 5 sequentially through the oil pipe 1 from top to bottom, and the terminal of the inclined tip 5 is 30 ° beveled slope, the water jet 3 is provided with eight symmetrically arranged nozzles, the nozzle aperture is 6 mm, and its process steps are as follows:

[0022] A. Run in hydraulic sand blasting perforation and fracturing process string: run in this process string so that the hydraulic injector 3 reaches the lower layer II position where perforation is required;

[0023] B. Positive washing: before perforating, wash the well with well-washing fluid. The displacement of the well...

Embodiment 2

[0029] Example 2: The oil well is 3500m deep, with upper and lower oil layers, the inner diameter of the casing is 124.3mm, and the outer diameter of the tubing is 73.03mm;

[0030] This method uses hydraulic sand blasting perforation and fracturing process pipe string operations, and the pipe string is connected to the safety joint 2, the hydraulic injector 3, the check valve 4 and the inclined tip 5 sequentially through the oil pipe 1 from top to bottom, and the terminal of the inclined tip 5 is Bevel with 40° bevel. The water power injector 3 has eight symmetrically arranged nozzles with a diameter of 6 mm. The process steps are as follows:

[0031] A. Run in hydraulic sand blasting perforation and fracturing process string: run in this process string so that the hydraulic injector 3 reaches the lower layer II position where perforation is required;

[0032] B. Positive washing: before perforating, wash the well with well-washing fluid. The displacement of the well-washing...

Embodiment 3

[0038] Example 3: The oil well is 3500m deep, with upper and lower oil layers, the inner diameter of the casing is 124.3mm, and the outer diameter of the coiled tubing is 1.75inmm;

[0039] This method uses hydraulic sand blasting perforation and fracturing process pipe string operations, and the pipe string is connected to the safety joint 2, the hydraulic injector 3, the check valve 4 and the inclined tip 5 sequentially through the oil pipe 1 from top to bottom, and the terminal of the inclined tip 5 is 40° oblique angle, the water jet 3 has three uniformly arranged nozzles, the nozzle aperture is 6mm, and the process steps are as follows:

[0040] A. Run in hydraulic sand blasting perforation and fracturing process string: run in this process string so that the hydraulic injector 3 reaches the lower layer II position where perforation is required;

[0041] B. Positive washing: before perforating, wash the well with well-washing fluid. The displacement of the well-washing we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com