High-purity barium hydroxide octahydrate purification production system and method

A kind of barium hydroxide, pure octahydrate technology, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of leakage, toxicity, harm to workers' health, etc., to prevent dust flying and improve safety factor , the effect of preventing escape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

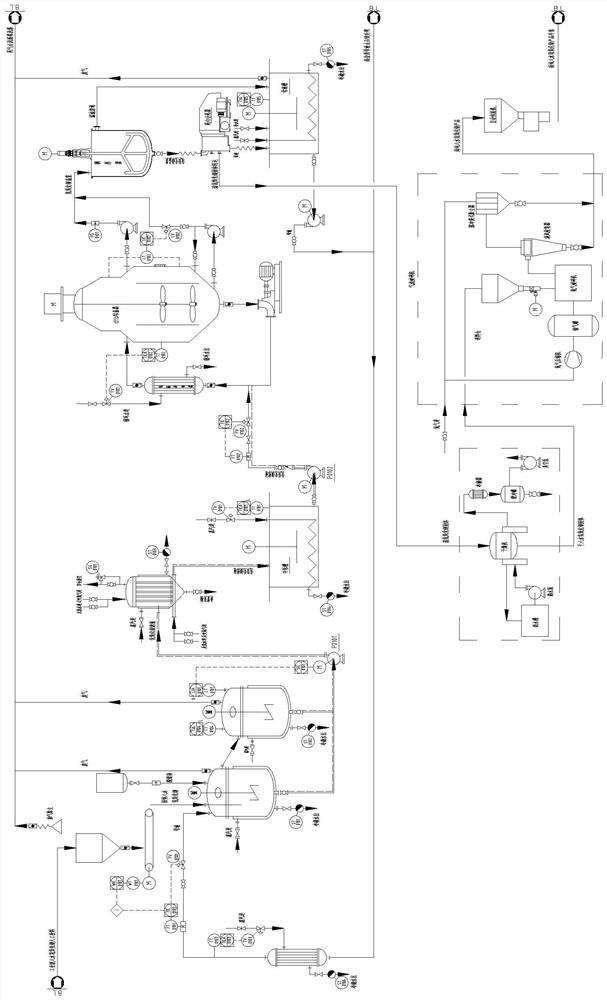

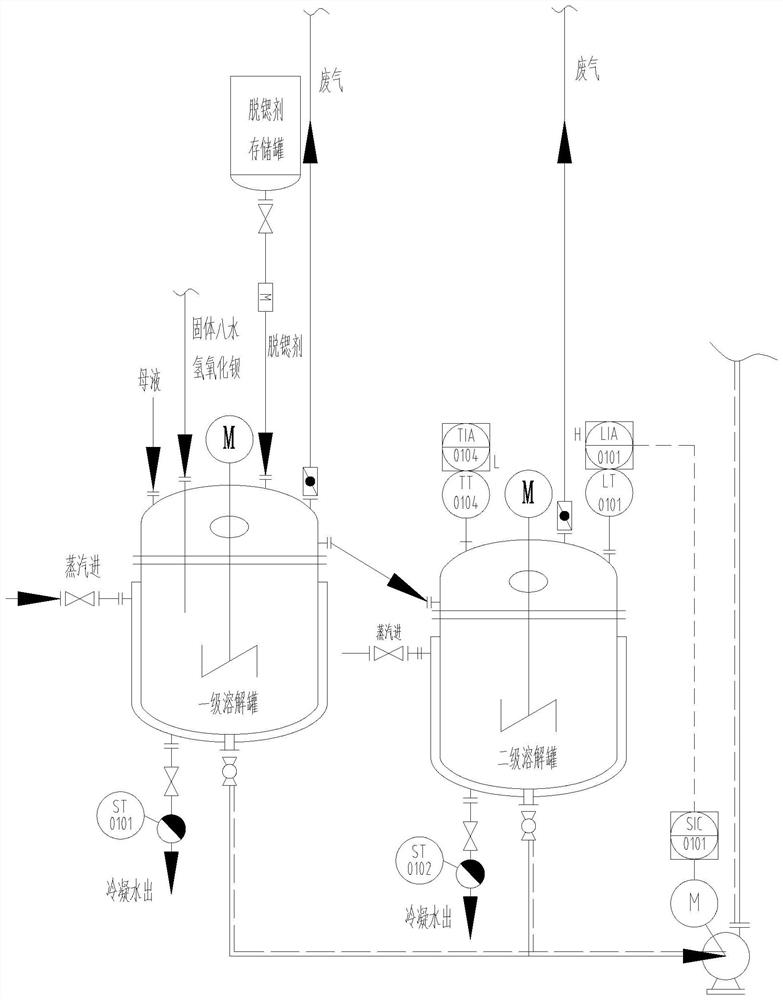

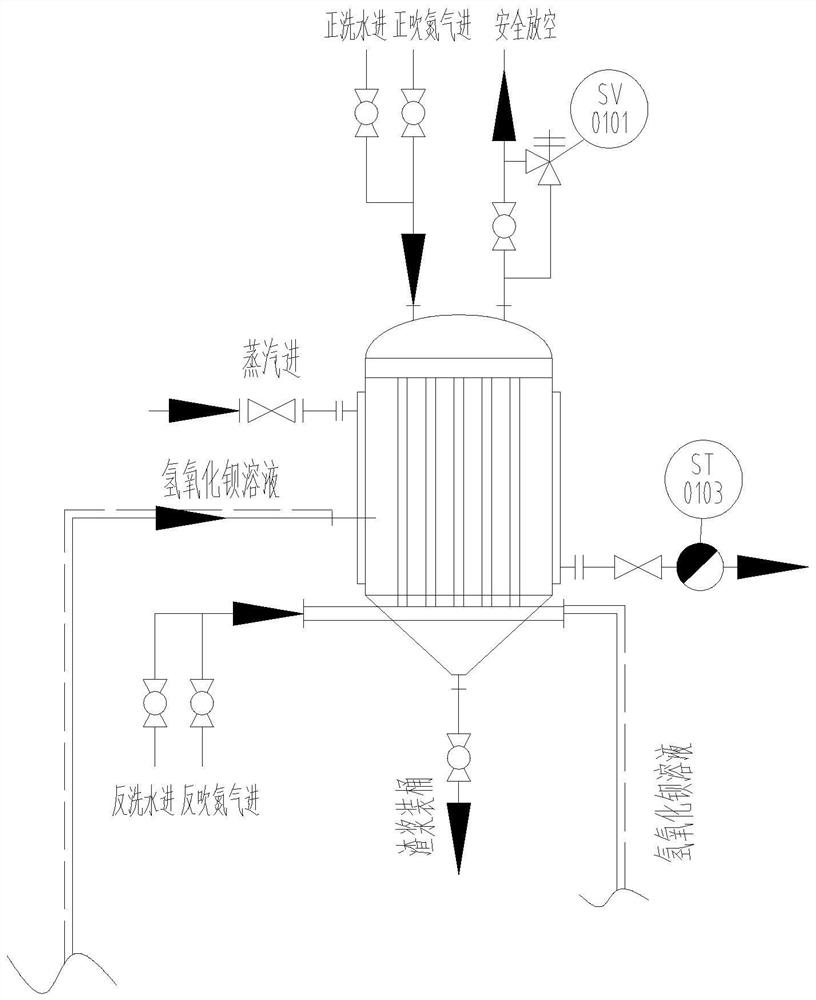

[0043] Such as figure 1 As shown, a high-purity octahydrate barium hydroxide purification production system includes a raw material warehouse, a mother liquor tank, a dissolution tank, a precision filter, a transfer tank, a DTB crystallization system, a thickener, a centrifugal separator, and a drying machines, jet crushers and automatic packaging machines. Among them, the raw material warehouse and the dissolution tank are connected by a metering belt, and the mother liquor tank, dissolution tank, precision filter, transfer tank, DTB crystallization system, thickener, centrifugal separator, dryer, air flow crusher and automatic packaging machine pass through the pipeline. Connected in turn, the pipelines are equipped with pump bodies and valves for controlling the normal transportation of materials. In this embodiment, the outer sides of the pipelines are equipped with insulation layers to keep the transported slurry warm and prevent crystals from being precipitated in the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com