Longitudinal absorber for reducing perforation instantaneous shock vibration force

A technology of instantaneous impact and vibration force, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of the decline of the sliding sealing performance of the inner and outer shaft sleeves, the possibility of accidental detonation, and the false detonation of the detonation device when the pressure is increased. problem, to achieve the effect of changing the environment of liquid compression and vibration reduction, solving the fragile dynamic seal, and improving safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

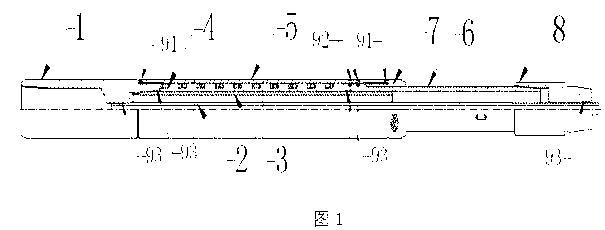

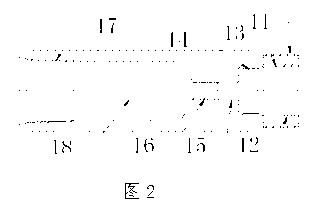

[0047] see figure 1 , the present invention reduces the structure of the longitudinal shock absorber of perforation instantaneous impact vibration force by upper joint 1, pressure guiding pipe 2, inner sleeve 3, spring 4, outer shell 5, outer sleeve 6, fixed ring 7, lower joint 8. The sealing member 93, the top wire 91 and the damping shear pin 92 are composed of the inner side of which is the pressure guiding tube 2, which is sequentially connected with the inner sleeve 3, the spring 4, and the outer sleeve 6, and the outermost end is the outer shell 5 and The fixed ring 7 is connected to the upper joint 1 and the lower joint 8 at the left and right ends of the outer side respectively, the sealing member 93 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com