Grinding device for mechanical accessory machining

A technology for mechanical accessories and grinding mechanisms, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc. It can solve problems such as inability to accurately adjust the grinding angle, affect the grinding effect of accessories, and large vibration force, etc., to achieve It is convenient for fine grinding, has good shock absorption effect and reduces the effect of vibration impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

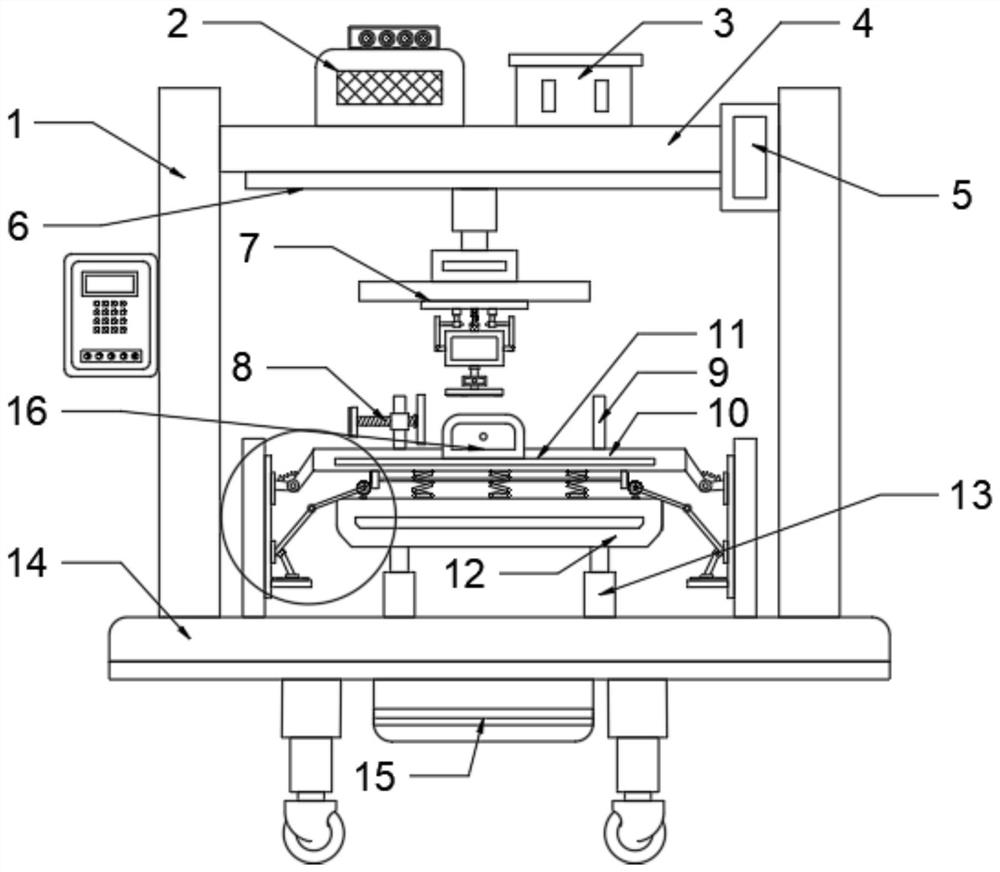

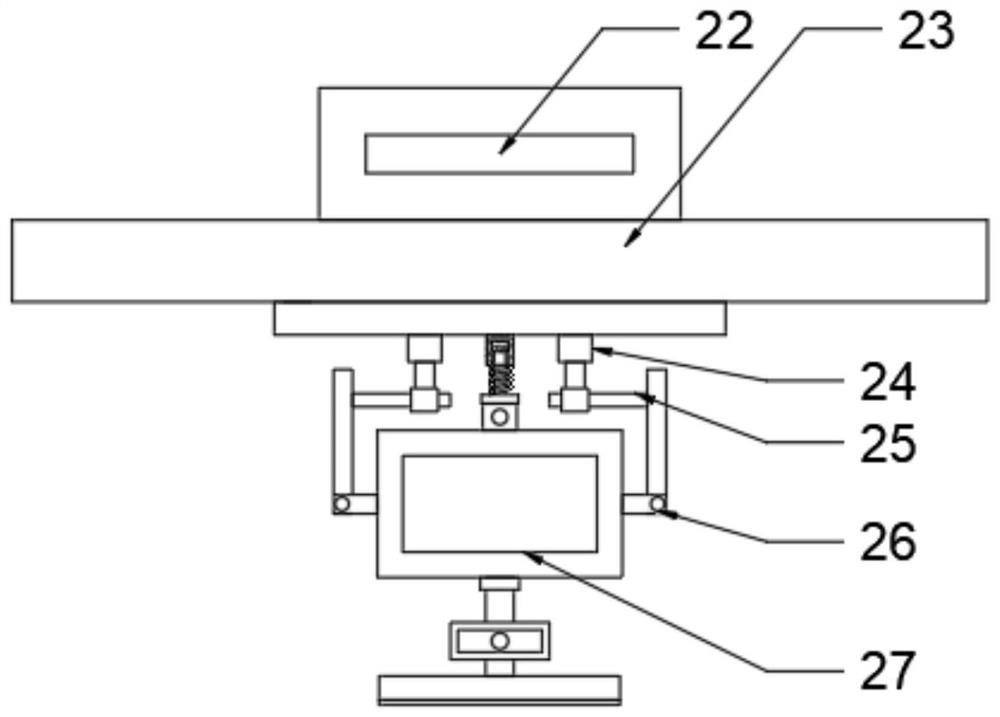

[0022] see Figure 1~4 , in an embodiment of the present invention, a grinding device for mechanical parts processing includes a base 14; a mounting frame 1 is installed on the top of the base 14; a top seat 4 is installed between the mounting frames 1; The bottom end of the seat 4 is connected to the grinding mechanism 7 through a horizontal adjustment mechanism; the top of the base 14 is provided with a placement plate 10 corresponding to the grinding mechanism 7; the placement plate 10 is provided with a clamping mechanism; the bottom of the placement plate 10 is installed There is a buffer mechanism; the placement plate 10 is connected to the fixed platform 12 through a buffer spring; the bottom of the fixed platform 12 is connected to the top of the base 14 through a hydraulic cylinder 13 .

[0023] Further, the horizontal adjustment mechanism includes No. 1 drive box 5 and slide rail 6; the No. 1 drive box 5 is installed on the top seat 4; the No. 1 drive box 5 is provid...

Embodiment 2

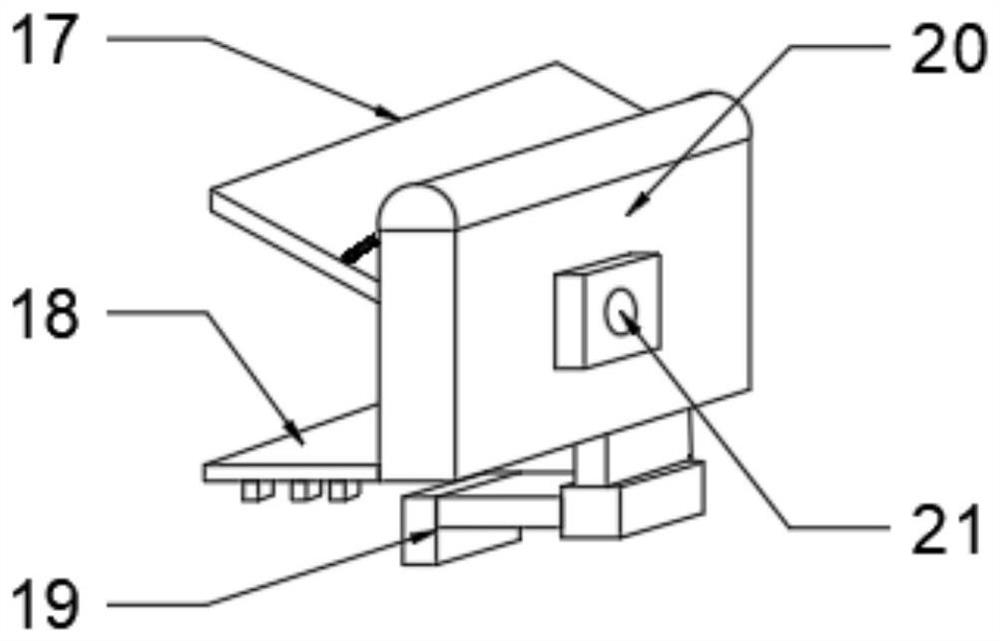

[0029] see figure 1 Or 2, a dust removal and drying mechanism 16 is installed on the placement plate 10; the dust removal and drying mechanism 16 includes a work box 20; a connector 21 is installed on one side of the work box 20; the other side of the work box 20 Pressure nozzle, waste baffle 17 and limit plate 18 are installed; Described waste baffle 17 is hinged working box 20; The top of described waste baffle 17 is connected working box 20 by spring bar; Described limit plate The bottom of 18 is equipped with a limit moving block; the top corresponding limit moving block of the placement plate 10 is provided with a limit moving groove; the connector 21 communicates with the working box 20; the connector 21 communicates with the water tank 3 through a water pipe; The connector 21 is connected to the dust removal fan 2 through the air pipe; the dust removal fan 2 is provided with a carbon fiber pipe heater; the water pipe and the air pipe are equipped with electromagnetic va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com